A newbie question, but here goes. Lets say you have a part with holes you can measure but not move to your mill or lathe. Youd like to make a copy of this part but whats making me scratch my head is how do you measure existing holes in relation to where they are located. I mean how could i measure existing holes to know EXACTLY where to layout holes to drill and copy a part.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Copying something precisely.

- Thread starter SoIll914

- Start date

- Joined

- Dec 20, 2012

- Messages

- 9,422

If the part to be reproduced can be removed then I would place it on the material you're going to make the new part from and trace the outline (to cut it to shape later) and then use transfer punches to mark the hole locations. Or, if the surface that your part will attach to has threaded holes you can make the new part minus the holes, thread some transfer screws into the holes, and put the new part in place. A tap over each transfer screw will mark the holes for you.

If the old part has square edges you can also just measure their locations. This is slower and has more potential for error. I would opt for the above myself.

If the old part has square edges you can also just measure their locations. This is slower and has more potential for error. I would opt for the above myself.

- Joined

- Sep 29, 2014

- Messages

- 2,102

What do you mean by "exactly"?

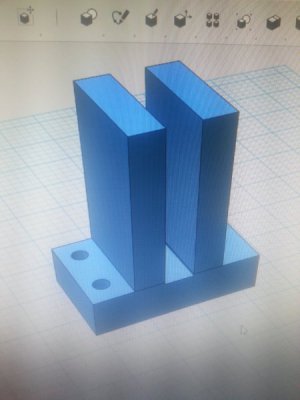

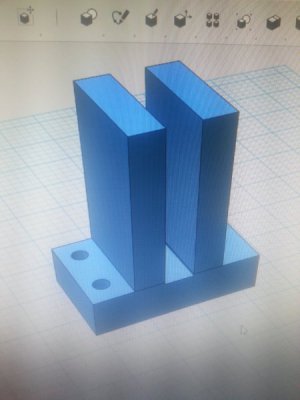

Basically this is the jist of the part. Probably 2" wide by 4" long by 5-6" tall. The thing im wanting to know is how to make these drill holes on a copied part line up as accurately as the part itself. Its not a part i think i can layout on paper and trace drill holes.

Edit: this part is a non critical part for a machine i run at my job. I wanted to try and make a replacement for practice but im new and do not know of the most accurate way to insure the bolt holes will line up.

Edit: this part is a non critical part for a machine i run at my job. I wanted to try and make a replacement for practice but im new and do not know of the most accurate way to insure the bolt holes will line up.

- Joined

- Feb 8, 2014

- Messages

- 11,176

I normally sit down and make a drawing of the part. This may take the form of a rough sketch with dimensions with pencil & paper for a simple part to a very detailed CAD drawing for something more complex.

The measuring is normally done with digital calipers, but I also have a small height gauge at my desk which simplifies some dimensions. Normally I will find the hole centers by measuring both hole edge to hole edge, then do the math to find the centers. The get hole edge to part edge in both the X and Y axis.

For maximum accuracy I use gauge pins in the holes and measure over those, then use a surface plate and height gauge or indicators for deriving the hole to edge distances. Measurements may also require the use of radius gauges and angle gauges.

How you approach the job depends on how accurate you need to be, using calipers will normally get you close enough for most work.

The measuring is normally done with digital calipers, but I also have a small height gauge at my desk which simplifies some dimensions. Normally I will find the hole centers by measuring both hole edge to hole edge, then do the math to find the centers. The get hole edge to part edge in both the X and Y axis.

For maximum accuracy I use gauge pins in the holes and measure over those, then use a surface plate and height gauge or indicators for deriving the hole to edge distances. Measurements may also require the use of radius gauges and angle gauges.

How you approach the job depends on how accurate you need to be, using calipers will normally get you close enough for most work.

- Joined

- Feb 8, 2014

- Messages

- 11,176

Basically this is the jist of the part. Probably 2" wide by 4" long by 5-6" tall. The thing im wanting to know is how to make these drill holes on a copied part line up as accurately as the part itself. Its not a part i think i can layout on paper and trace drill holes.

Edit: this part is a non critical part for a machine i run at my job. I wanted to try and make a replacement for practice but im new and do not know of the most accurate way to insure the bolt holes will line up.

If you can measure the original part, then just use those numbers to drill the holes on your mill. Start at one corner and get absolute X/Y dimensions to the hole locations. Even if you don't have a DRO, this is simple, just trust your dials and count turns. I did tool & die work that way for years.

- Joined

- Feb 8, 2014

- Messages

- 11,176

Do you not trust your vernier or your ability to use them? For most work, you will be fine. I don't know that accuracy this job requires, but you should be able to measure +/- 0.001. Typically you would drill the hole 0.016 to 0.032 oversize for standard clearance.