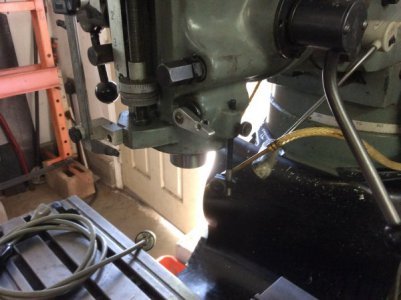

Guys been working on my BP putting it together and installing DRO.The repairs and the DRO is going slow cause I order parts little at a time as money permits.So during the times that I am waiting I watch Youtubes,and I see lot of people use coolant during their cuts I guess for longer tool life.One of the materials that I plan on using once I get some experience is stainless steel,and 6061,7515 aluminum along with mild steel who knows what else.I know there is other choices besides SS but thats what I want to use till I learn the hard way.Anyway back to my question I see on Youtube that most use I believe is a mist type,some look like system was purchase then I see some are home made but both I guess you have an air compressor hook up to it.But also believe after using will have to clean,dry then apply coat of oil to BP to prevent rust?So is a coolant system worth having,what system do you have and where to purchase on a limited type budget.Maybe I don't really need one being a weekend'er.Pros/Cons

Reason for asking while I have it out in middle of the room and can get to all sides,just want to get it all setup and be done with it.I look at this as small investments into the mill so that it will have it all and when the day comes that I can't use it anymore that it will be an easy sell.

Reason for asking while I have it out in middle of the room and can get to all sides,just want to get it all setup and be done with it.I look at this as small investments into the mill so that it will have it all and when the day comes that I can't use it anymore that it will be an easy sell.

Last edited: