- Joined

- Nov 27, 2012

- Messages

- 7,912

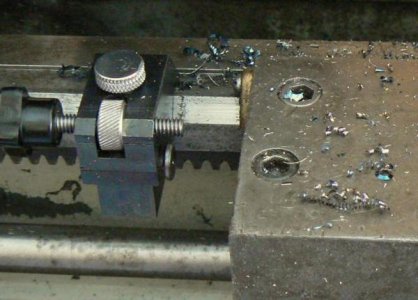

I'm a big fan of single diagonal knurling. I still use 2 wheels to achieve the knurl but with both the same directional wheels. I use 2 wheels cause knurling Ti 6Al4V is not that easy depending on the type of knurl desired. I use a K1-44 heavy duty scissor knurl.

Sorry for the brief hijack. Thanks for this thread to remind me that I need to finish working on my micrometer carriage stop.