J,

As you surmised, it does have babbit spindle bearings. Even without the model number on the nameplate, you can tell because the other choice (tapered roller bearings) does not have removable bearing caps attached with two cap screws (hex head bolts). However, if they were properly lubricated (oiled before every use), odds are that they are still OK. All of the babbit bearing equipped machines came with shim packs under each bolt. Perhaps the first thing to do to evaluate them is to remove the bearing caps one at a time and mic the two packs that should be under each bearing cap. The original shim packs were 0.010" thick and were made up of five 0.002" shims. So, after you have gone through the bearing adjustment procedure, the remaining shim pack thickness is an indication of how much wear has occurred in the bearings. Unless they prove to be worn out, which is unlikely, I wouldn't worry about replacing the headstock with the Timken model.

From the rectangular motor switch mounting plate, the lathe was made no earlier than 1942. From the serial number compared to some with Timken bearings where the bearing dates are known, it was 1942.

To check the bearings, you need to find (or acquire) the Manual of Lathe Operation (MOLO) that came with the lathe. It will have black covers and the binding may in 1942 have been either white multi-finger plastic, or spiral wire binding. Most likely the wire and most likely the wire is in three pieces, but if you do find it, please report on what the binding was, and if wire, whether one piece, two pieces, or three.

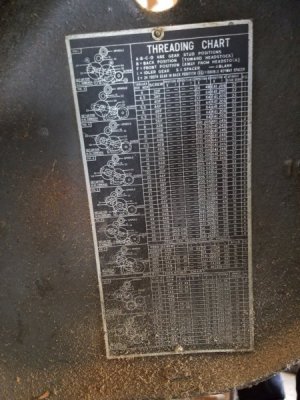

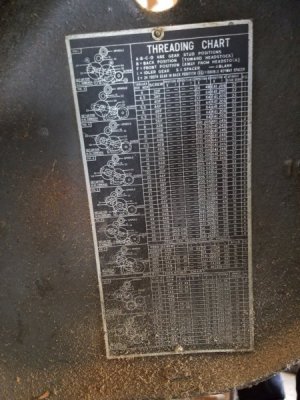

Starting on page 9 in the MOLO is the discussion of the babbit bearings, including how to adjust them. The manual also says on page 5 to use SAE 10 engine oil where oil is specified for lubrication. However, sometime in the late 1950's, Atlas changed this recommendation to SAE 20. Which is what I would use. If you cannot locate the original manual, they are often listed on eBay. As over the years, there have been at least 10 versions, you need to make sure which version you are buying. If the covers are gray with an Atlas logo or black with the word Craftsman on the front cover, they will not cover babbit bearings. The one that you need will have black covers with the Atlas logo, and on the first or second page of Part 7 - Threading, will mention the Atlas F-Series Ten Inch lathe. Most likely, it will have white plastic binding but may still have the wire binding.

As far as a fair price to pay for it, you do need to find out how many accessories, if any, are there. All that is visible in the photos is the 3-jaw chuck and either a live center or a small drill chuck in the tailstock. As a general rule of thumb, each accessory, if bought separately, will cost you between $100 and $200. So, assuming that the spindle bearings are still in good condition, start with $400 for the lathe and add $75 to $100 for each significant accessory found. Generally, don't add anything for cutters and other minor bits.