F

f350ca

Forum Guest

Register Today

Hope this project fits the forum, it has a bit of everything.

This will be the third set of counters I've done over about 10 years. The basic counter recipe has stayed the same but the finishing is evolving.

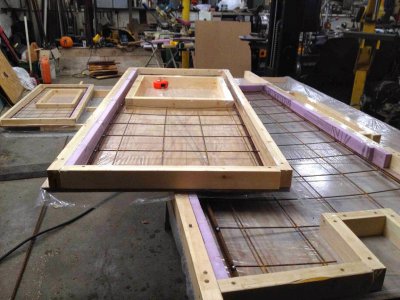

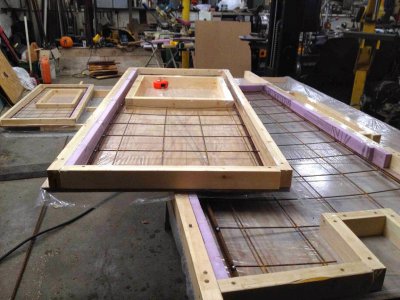

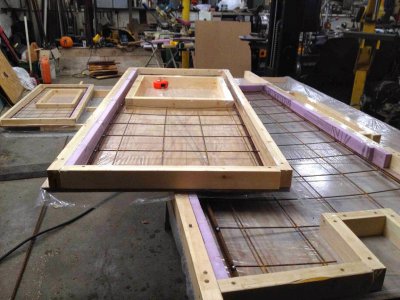

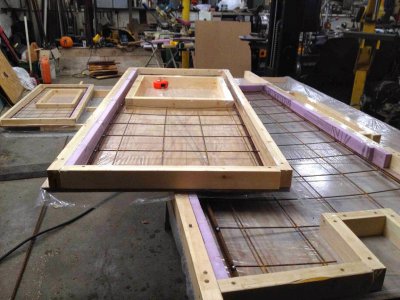

The counters are built with a regular portland cement core, about 1 1/2 inch thick. It is reinforced with 1/2 rebar around the perimeter and 6 x 6 mesh through the body. Fiber glass chop is used and a water reducer to minimize shrinkage. The surface is poured about 3/4 thick using a decorative stone mixed with white portland dyed to what ever colour. This set has white 3/8 marble chips with grey dyed cement.

These are cast in my shop and moved to location. They are heavy, I wouldn't be comfortable putting them on stock particle board carcasses. These are finishing off a set of cabinets I build last winter, the bases are formed from 3/4 birch plywood with hardwood faces.

Here are the forms set up with rebar and mesh in place. The styrofoam strips keep the base portland off the edges that need to be finished.

This will be the third set of counters I've done over about 10 years. The basic counter recipe has stayed the same but the finishing is evolving.

The counters are built with a regular portland cement core, about 1 1/2 inch thick. It is reinforced with 1/2 rebar around the perimeter and 6 x 6 mesh through the body. Fiber glass chop is used and a water reducer to minimize shrinkage. The surface is poured about 3/4 thick using a decorative stone mixed with white portland dyed to what ever colour. This set has white 3/8 marble chips with grey dyed cement.

These are cast in my shop and moved to location. They are heavy, I wouldn't be comfortable putting them on stock particle board carcasses. These are finishing off a set of cabinets I build last winter, the bases are formed from 3/4 birch plywood with hardwood faces.

Here are the forms set up with rebar and mesh in place. The styrofoam strips keep the base portland off the edges that need to be finished.