- Joined

- Feb 24, 2019

- Messages

- 957

I have a project that I'm designing in my head. I've purchased a couple components that I am sure I can fit together using liquid nitrogen, rather than press fitting.

I have a bearing that has a .750 OD which will fit into a 19mm ID piece. .002 size isn't worrisome in those dimensions. I'll freeze the bearing and it should compression fit nicely when it comes back to temp.

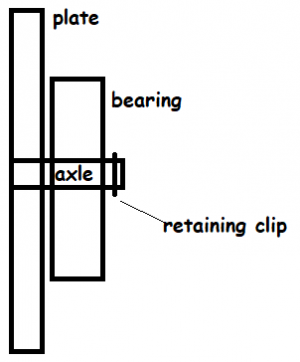

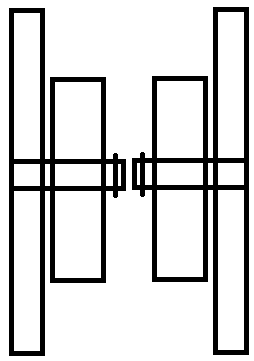

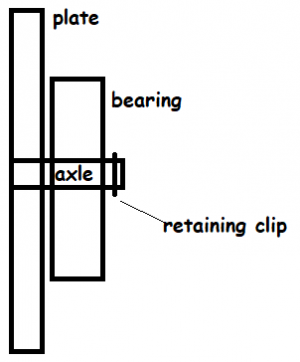

Now I need to think about the axle for the bearing. The ID of the bearing is .250"

I want to compression fit the axle to a vertical plate. I am imagining the .250" axle, dropped in nitrogen, but don't know how much it will shrink. Yes, I know different metals have a different shrink ratio which is part of where I'm hung up. I don't know what type of metal (steel alloy) I want to use for the vertical plate or axle.

I also don't mind heating the vertical plate to expand it a little while fitting the axle.

For the metal plate, I'd have the initial part waterjet cut and then do the final machining. It can't be so hard that I can't machine it with my Smithy and the HSS reamer(s) I will buy but mild steel won't work at all.

So, I guess my questions are:

What would be the best alloy to use for the axle plate?

What would be the best alloy to use for the axle itself?

What size ream would I need for a .250" axle using Nitrogen compression using the axle alloy from above?

Yeah, I can research all this. I'm not asking anyone to do the research work for me. Just opening a discussion.

I have a bearing that has a .750 OD which will fit into a 19mm ID piece. .002 size isn't worrisome in those dimensions. I'll freeze the bearing and it should compression fit nicely when it comes back to temp.

Now I need to think about the axle for the bearing. The ID of the bearing is .250"

I want to compression fit the axle to a vertical plate. I am imagining the .250" axle, dropped in nitrogen, but don't know how much it will shrink. Yes, I know different metals have a different shrink ratio which is part of where I'm hung up. I don't know what type of metal (steel alloy) I want to use for the vertical plate or axle.

I also don't mind heating the vertical plate to expand it a little while fitting the axle.

For the metal plate, I'd have the initial part waterjet cut and then do the final machining. It can't be so hard that I can't machine it with my Smithy and the HSS reamer(s) I will buy but mild steel won't work at all.

So, I guess my questions are:

What would be the best alloy to use for the axle plate?

What would be the best alloy to use for the axle itself?

What size ream would I need for a .250" axle using Nitrogen compression using the axle alloy from above?

Yeah, I can research all this. I'm not asking anyone to do the research work for me. Just opening a discussion.