- Joined

- Apr 24, 2022

- Messages

- 182

Hello all,

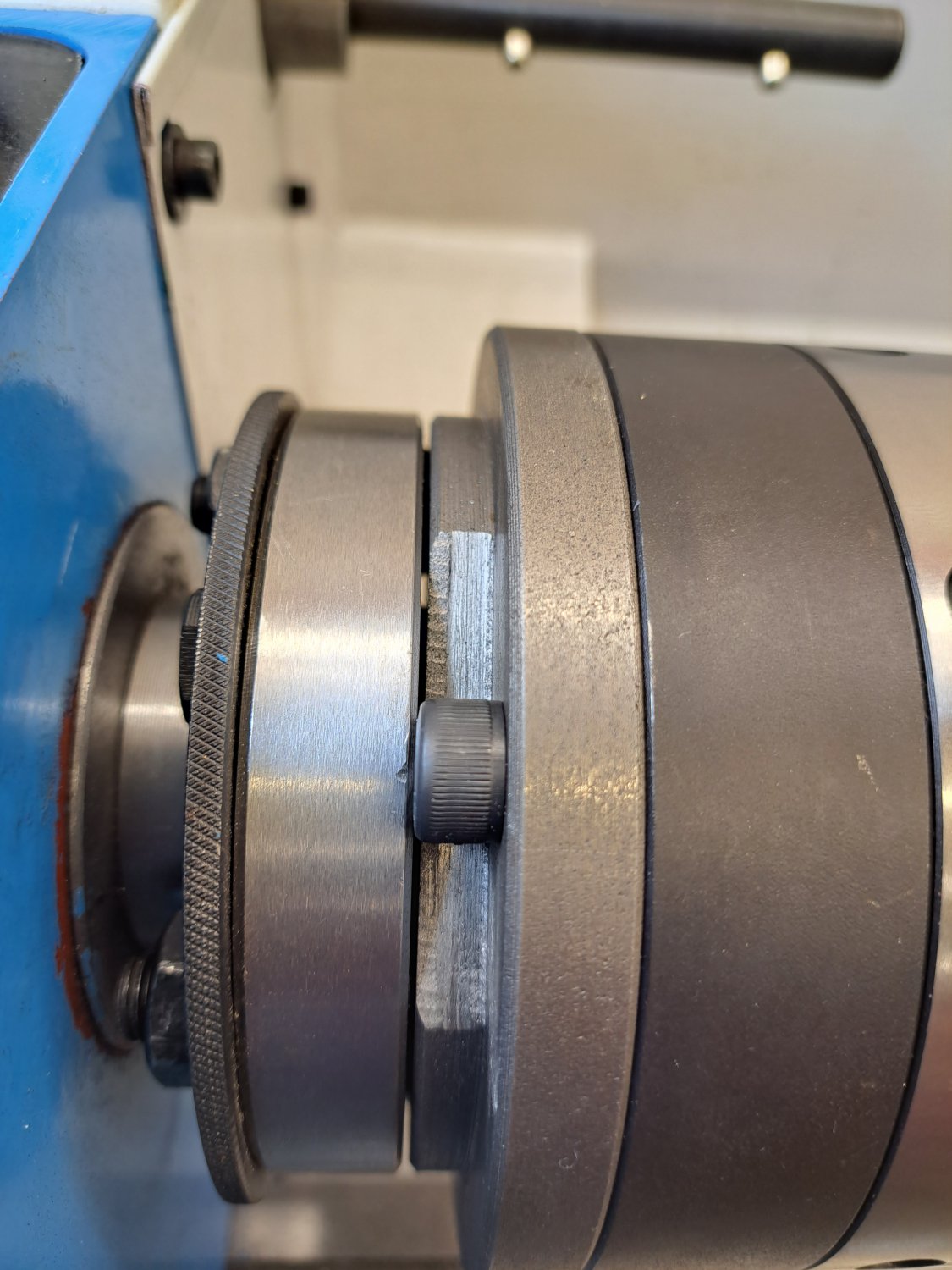

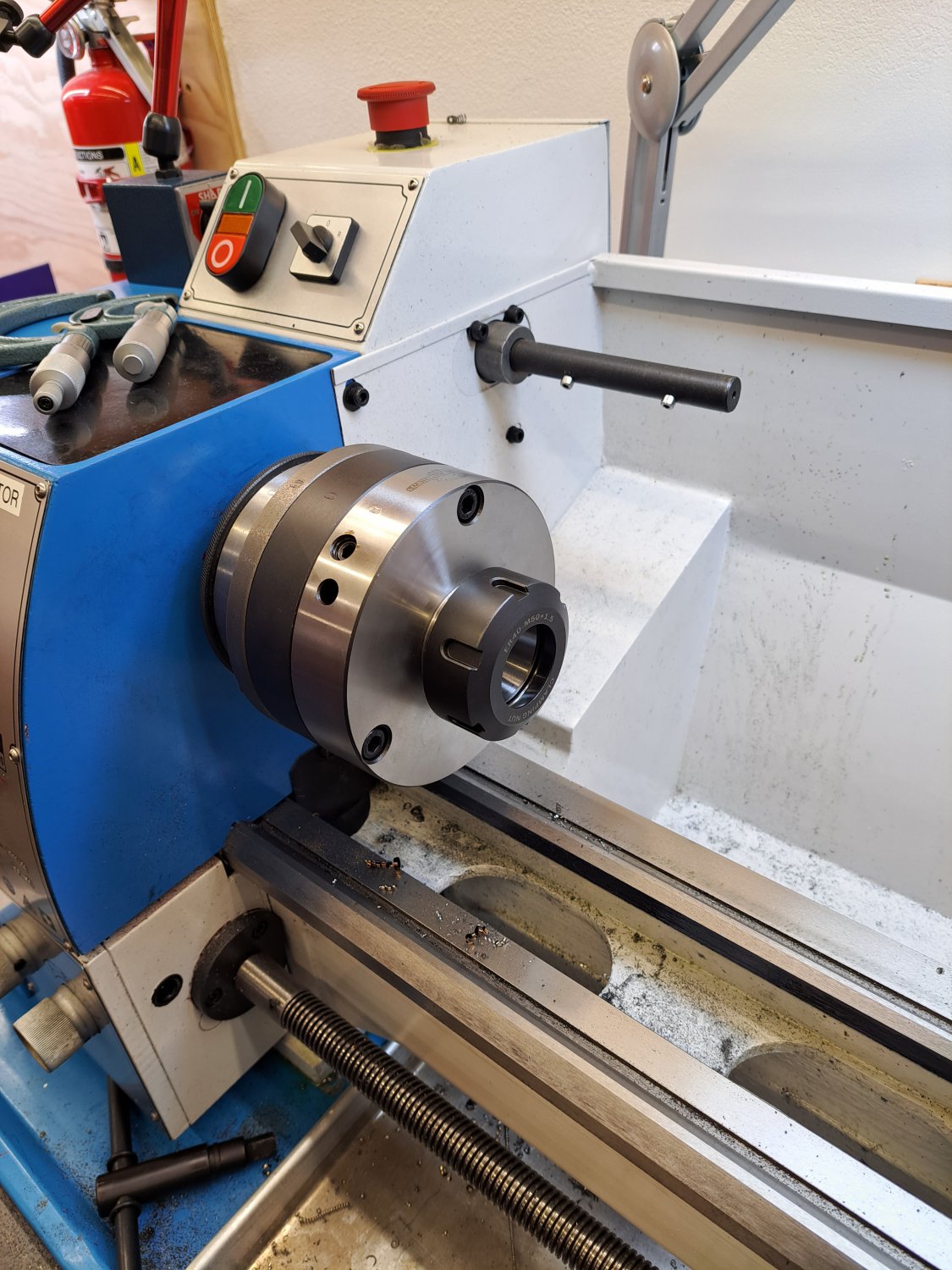

Thought I'd share how I adapted a PM Tru-Set ER40 collet chuck with D1-4 mount to fit a PM1022 or 1030-V spindle. The PM D1-4 collet chuck doesn't fit the 1022 or 1030 lathes out of the box, but adapting it is pretty straight forward.

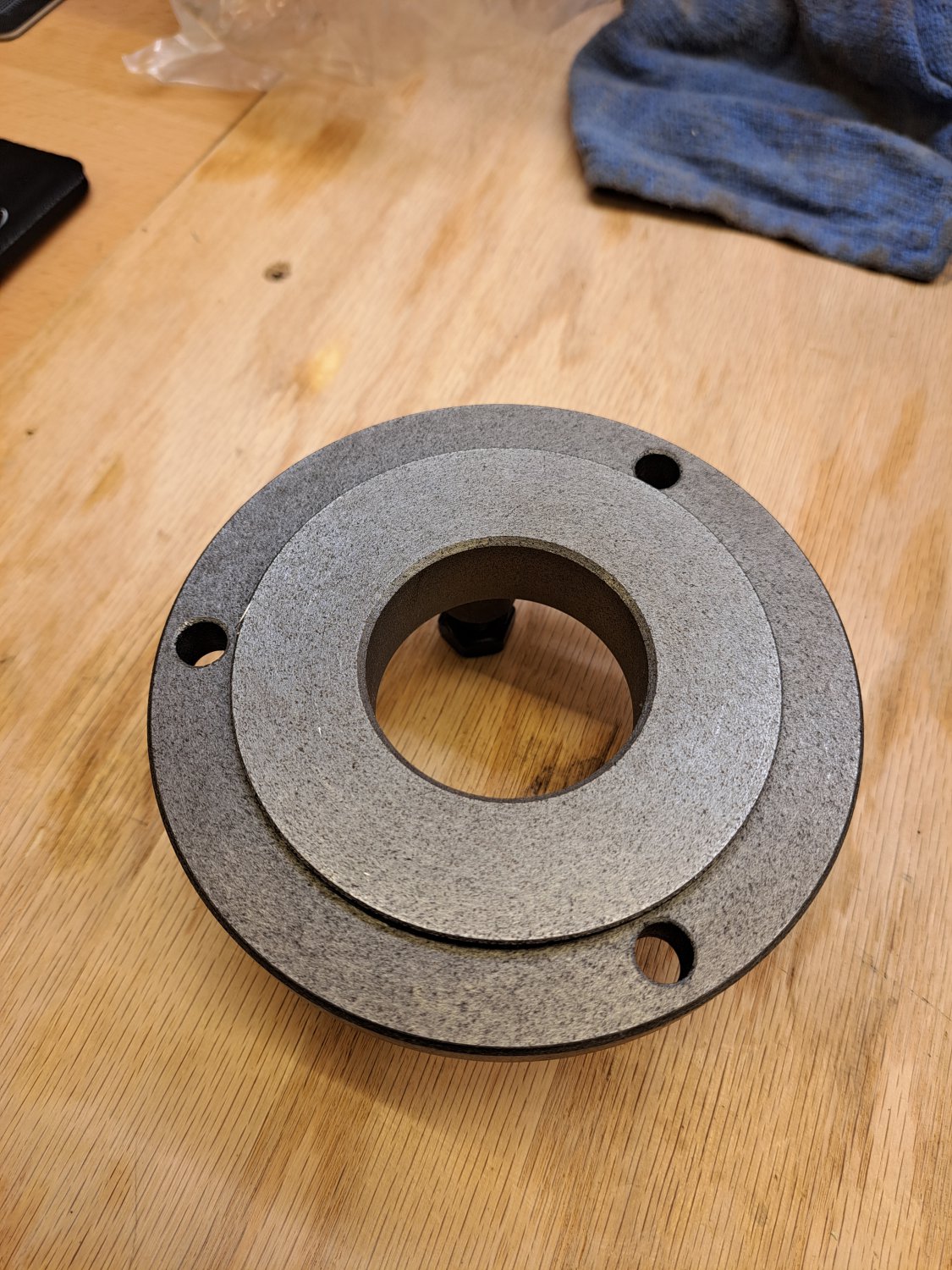

The chuck is two pieces bolted together using the common (for 4-6" chucks) 3 hole on a 4.250" bolt circle arrangement. Back half is the mount plate with a protruding hub, front half is the collet holder with a recess for the hub on the mount plate - this hub is what the trust bolts push against to adjust runout. Back has a centering taper (approx 2.5" at widest) on the backing plate meant for the D1-4 spindle.

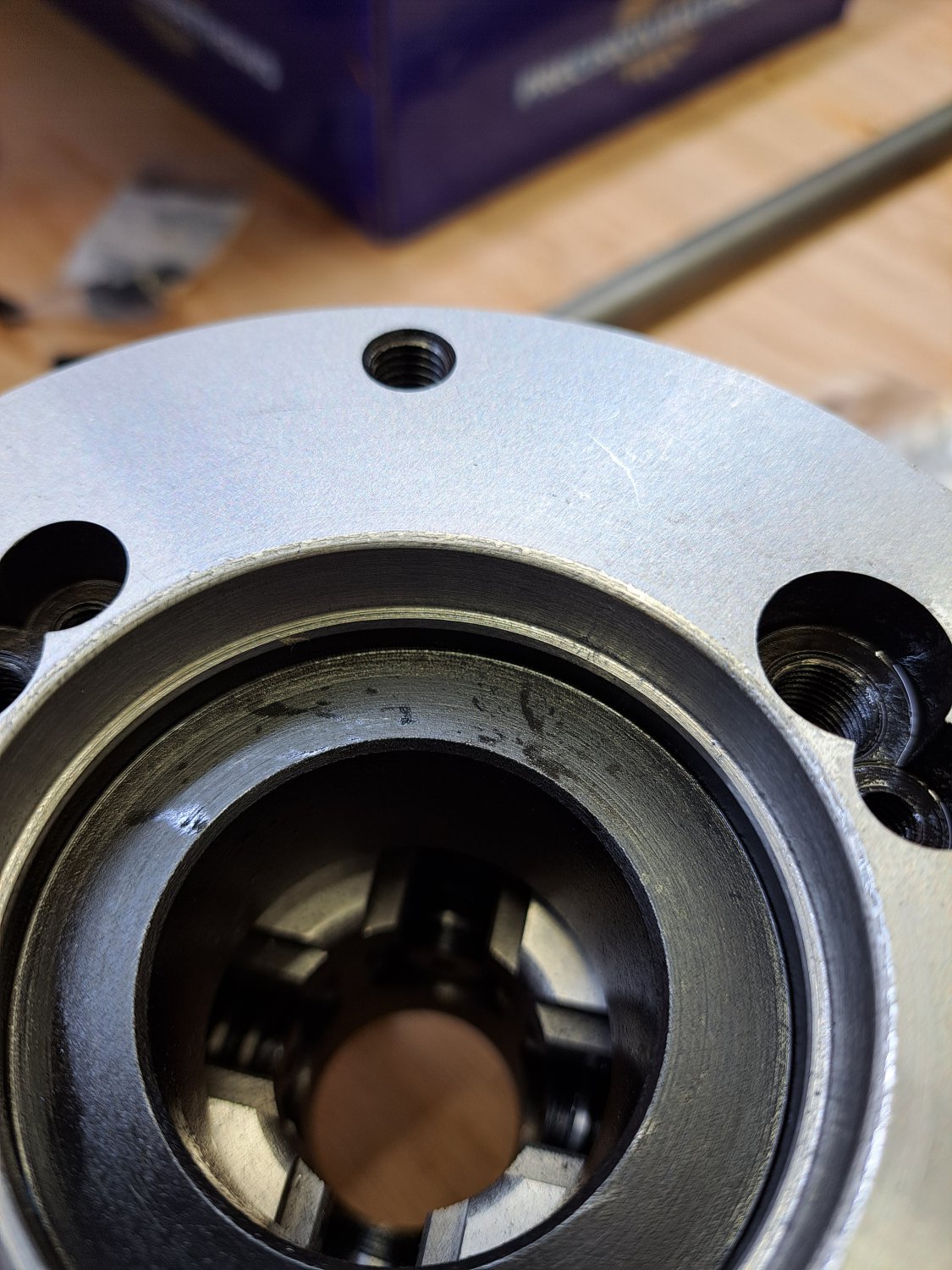

I bought a couple extra spindle mount plates from PM with the Lathe, anticipating to use one for a collet chuck project. Those also have holes at the 3-on-4.25"-circle. They have a centering hub that is roughly 3.75" in Dia.

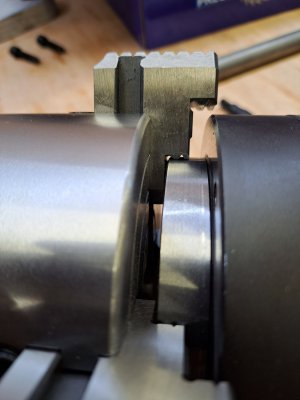

So, all the needs to be done is to separate the chuck and bore the tapered hole square. I just chucked it in a 4-jaw and dialed it in using an indicator running on the mounting taper. Figured that would be concentric to the collet holder. Ended up with a 2.500" centering shoulder.

(Don't laugh too hard at the crappy chamfer

(Don't laugh too hard at the crappy chamfer

Then mounted the spare 1022/1030 mount, and turned the shoulder down to 2.498", for a nice snug fit to the collet chuck mount plate. ( It's cast iron, so...)

.

.

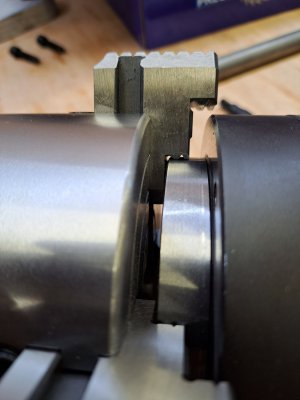

3 M8x25 bolts will be needed. Take .040" off the bolt faces for clearance, and bolted it all together. Was able to dial the chuck to less than a tenth, with indicator riding on the collet taper, so I'm happy. Should provide good utility, didn't cost much, easy to make, and there were few options available for the 1022/1030, so I have no complaints.

Thought I'd share how I adapted a PM Tru-Set ER40 collet chuck with D1-4 mount to fit a PM1022 or 1030-V spindle. The PM D1-4 collet chuck doesn't fit the 1022 or 1030 lathes out of the box, but adapting it is pretty straight forward.

The chuck is two pieces bolted together using the common (for 4-6" chucks) 3 hole on a 4.250" bolt circle arrangement. Back half is the mount plate with a protruding hub, front half is the collet holder with a recess for the hub on the mount plate - this hub is what the trust bolts push against to adjust runout. Back has a centering taper (approx 2.5" at widest) on the backing plate meant for the D1-4 spindle.

I bought a couple extra spindle mount plates from PM with the Lathe, anticipating to use one for a collet chuck project. Those also have holes at the 3-on-4.25"-circle. They have a centering hub that is roughly 3.75" in Dia.

So, all the needs to be done is to separate the chuck and bore the tapered hole square. I just chucked it in a 4-jaw and dialed it in using an indicator running on the mounting taper. Figured that would be concentric to the collet holder. Ended up with a 2.500" centering shoulder.

(Don't laugh too hard at the crappy chamfer

(Don't laugh too hard at the crappy chamfer Then mounted the spare 1022/1030 mount, and turned the shoulder down to 2.498", for a nice snug fit to the collet chuck mount plate. ( It's cast iron, so...)

3 M8x25 bolts will be needed. Take .040" off the bolt faces for clearance, and bolted it all together. Was able to dial the chuck to less than a tenth, with indicator riding on the collet taper, so I'm happy. Should provide good utility, didn't cost much, easy to make, and there were few options available for the 1022/1030, so I have no complaints.