- Joined

- Feb 8, 2014

- Messages

- 11,176

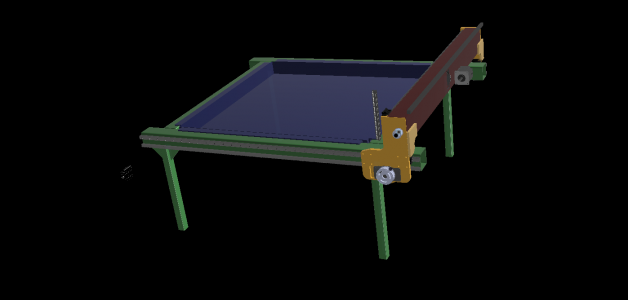

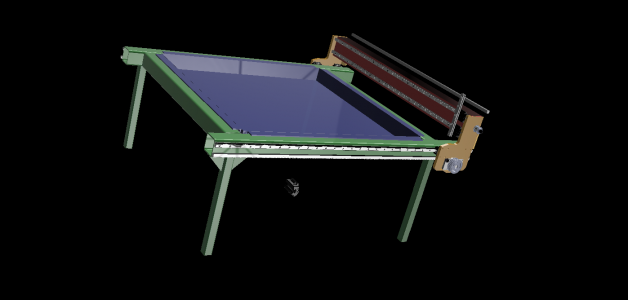

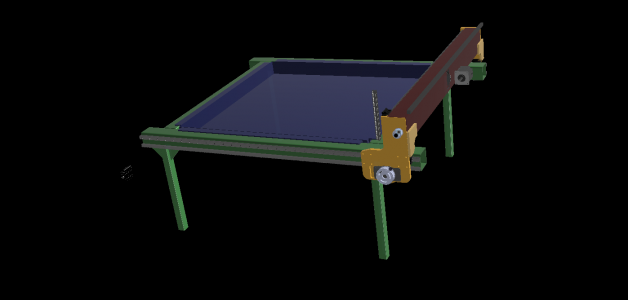

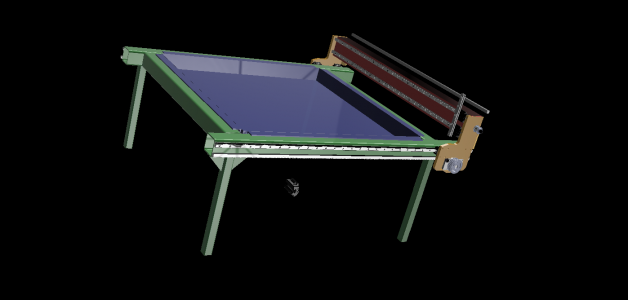

A little teaser:

I now have a need for a CNC plasma cutter. I have been avoiding this for a long time because they are messy and I really don’t have room for one in my shop. But, we want to bring the parts in-house that we are currently having laser cut. And I have been requested to develop the software and control system to retrofit some existing CNC plasma machines. So I’m being dragged into this kicking and screaming all the way.

This will start out as an experimental machine and then transition into a production machine for our in-house use.

The three primary goals are: 1) Develop an integrated Torch Height Control, 2) Achieve near laser cut quality in our 11ga 304SS parts, and 3) Achieve laser quality cuts in small holes (0.201’’ in this case). The last is the most difficult of the goals, if it is even possible.

I looked at buying a plasma table but there is nothing available that meets my design criteria. I want a 48x48’’ work area, and when you get into that size of a machine they are all very light duty hobby class machines. Not up to the task. So I have no choice but to build my own.

Design Criteria:

Heavy and very rigid base frame, but still portable(ish) (<1000 lbs total weight) I need to be able to set it on the shelf when not in use.

Capable of 1000 IPM rapids

Capable of at least 1G acceleration

Cutting speeds to 500 IPM for thin materials

Torch positioning to +/- 0.001’’ or better under all operating conditions

Backlash elimination system.

Gantry mass <50Kg (110 lbs.)

Single motor gantry drive

Rack & pinion drive system on X & Y axis

Water table

Capable of accepting a drill motor on the Z-axis in case the small hole functionality is not possible.

Omni-directional torch breakaway to prevent a catastrophic crash.

Operating system: My software and running a Galil motion controller.

Here is what I have so far. I am slowly learning how to design in Fusion 360. Base frame is 4x4x1/4 wall square steel tubing. Gantry is 4x6x1/4 wall aluminum tubing with aluminum end plates. Water tank is 14Ga SS. 25mm square THK rails.

Understand that this is a work in progress and I haven't gotten all of the parts designed yet.

I now have a need for a CNC plasma cutter. I have been avoiding this for a long time because they are messy and I really don’t have room for one in my shop. But, we want to bring the parts in-house that we are currently having laser cut. And I have been requested to develop the software and control system to retrofit some existing CNC plasma machines. So I’m being dragged into this kicking and screaming all the way.

This will start out as an experimental machine and then transition into a production machine for our in-house use.

The three primary goals are: 1) Develop an integrated Torch Height Control, 2) Achieve near laser cut quality in our 11ga 304SS parts, and 3) Achieve laser quality cuts in small holes (0.201’’ in this case). The last is the most difficult of the goals, if it is even possible.

I looked at buying a plasma table but there is nothing available that meets my design criteria. I want a 48x48’’ work area, and when you get into that size of a machine they are all very light duty hobby class machines. Not up to the task. So I have no choice but to build my own.

Design Criteria:

Heavy and very rigid base frame, but still portable(ish) (<1000 lbs total weight) I need to be able to set it on the shelf when not in use.

Capable of 1000 IPM rapids

Capable of at least 1G acceleration

Cutting speeds to 500 IPM for thin materials

Torch positioning to +/- 0.001’’ or better under all operating conditions

Backlash elimination system.

Gantry mass <50Kg (110 lbs.)

Single motor gantry drive

Rack & pinion drive system on X & Y axis

Water table

Capable of accepting a drill motor on the Z-axis in case the small hole functionality is not possible.

Omni-directional torch breakaway to prevent a catastrophic crash.

Operating system: My software and running a Galil motion controller.

Here is what I have so far. I am slowly learning how to design in Fusion 360. Base frame is 4x4x1/4 wall square steel tubing. Gantry is 4x6x1/4 wall aluminum tubing with aluminum end plates. Water tank is 14Ga SS. 25mm square THK rails.

Understand that this is a work in progress and I haven't gotten all of the parts designed yet.