Do we have any users with cnc plasma tables? I bought one used that needed some help and every time I think I have it running it throws me a curve. Right now I'm trying to cut some 1/2" steel, I've never cut more than 1/4" so I ran some tests and got it working fairly good, not great but serviceable. the test was a 2" square and everything was working ok until I tried to cut the actual part... then it didn't pierce and boiled molten goo up around the tip and blew out the side of my last good tip.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

CNC Plasma?

- Thread starter bpimm

- Start date

- Joined

- Aug 6, 2013

- Messages

- 336

I've had 3 or so tables over the last 10-15 years. Mostly as a hobby. Latest is a Fineline Saturn table with a removable water table tray top and hypertherm 45xp. While I don't use it daily, It's like a mill or a lathe... once you have one, you don't want to be without one & if you want or need a part cut out, it sure comes in handy! Most of all even after years, I'm still amazed when I watch one cut metal.

Last edited:

I agree they're handy to have, I just wish I could get it reliable enough to just use it and not have to fight it every time I want to use it. Mine uses a Miller 625 X-treme plasma unit and c & cnc controls. I knew it needed to be rewired when I bought it nothing was shielded and the wiring was a bit sloppy like all the limit switches were torn up because they put them on backwards so they would hook instead of riding up on the contact surface. now I guess I just need to work through all the bugs but it's hard when you only use it a few times a month.

The 625 is rated to cut 5/8" and sever 3/4" but the cut looked good for about 3/8" then it curved away from the travel direction. Travel direction is left to right. The material is a scrap I picked up somewhere I think it's mild steel, it works like it and it has a fairly heavy rust coating but I ground that away for the ground clamp and the cut area. Any ideas what to look for as a cause?

Thanks

Brian

The 625 is rated to cut 5/8" and sever 3/4" but the cut looked good for about 3/8" then it curved away from the travel direction. Travel direction is left to right. The material is a scrap I picked up somewhere I think it's mild steel, it works like it and it has a fairly heavy rust coating but I ground that away for the ground clamp and the cut area. Any ideas what to look for as a cause?

Thanks

Brian

F

f350ca

Forum Guest

Register Today

Looks like the torch was advancing faster than the jet could clear the cut. My Hyper Therm lists optimum cut speeds, and yes it will cut at those speeds but going about half the recommended speed gives sharper, straighter edges especially when cutting circles. Nozzles would seam to blow out one side going around small circles, slowing down stopped this.

Does your software generate a lead in for the pierce and does the table lower the torch during the lead in? Without those piercing 1/2 plate is going to be a problem.

Greg

Does your software generate a lead in for the pierce and does the table lower the torch during the lead in? Without those piercing 1/2 plate is going to be a problem.

Greg

I thought the same thing and slowed it down but I think I already had tip damage by then. I'll try slower when I get home next week with a new tip. That was at the recommended speed so I'll try half.Looks like the torch was advancing faster than the jet could clear the cut. My Hyper Therm lists optimum cut speeds, and yes it will cut at those speeds but going about half the recommended speed gives sharper, straighter edges especially when cutting circles. Nozzles would seam to blow out one side going around small circles, slowing down stopped this.

Does your software generate a lead in for the pierce and does the table lower the torch during the lead in? Without those piercing 1/2 plate is going to be a problem.

Greg

The test was all strait cuts but the part had 1/2" holes and that seemed to be where the problems started, and they did blow out the side so that tracks.

The software does generate lead ins but I think it but I think it lowers the torch in one stab before it moves, I'll check on that.

Is it even possible to cut a 1/2" hole in 1/2" material?

Thanks

F

f350ca

Forum Guest

Register Today

It will probably do it but they won't be pretty.

Greg

Greg

- Joined

- May 7, 2014

- Messages

- 776

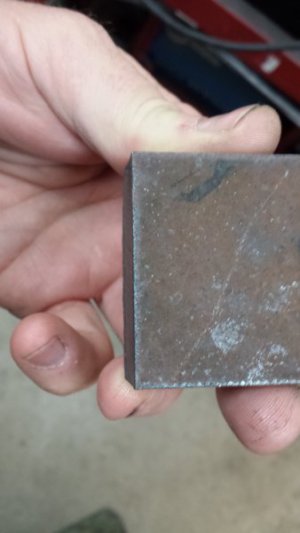

Hi all.. will chime in a bit. Can you show the top edge in that pic? My thought as I looked it.. Is there a THC (Torch Height Controller on this? If the torch drifts up, the deeper downward cutting ability quickly starts to fail. (on mine anyway).. dialing in for 3/4 and such w/ flat plate you can set the initial pierce height, then then any delays on the pierce, then the THC delay starts. (just flat torch cutting). Once that settles and it start moving, THC kicks in. Then it begins to try and maintain the tip voltage.(or what ever it is measuring by drifting up or down. If you cut 2 or more pieces and they look like that... my wager is that it's a parm of some type. Only since I had to fiddle with my rig so many tims on this stuff. If THC is on while doing this, turn it off?

The CandCNC manuals from Tom are a great troublshooting source. even for non CandCNC controllers. his TS approach is very concrete. The 'straight line' cutting tests... you can find them on candcnc.com under manuals. look into the bladerunner manuals. if you cannot locate, give me a shout.

best

Jeff,

The CandCNC manuals from Tom are a great troublshooting source. even for non CandCNC controllers. his TS approach is very concrete. The 'straight line' cutting tests... you can find them on candcnc.com under manuals. look into the bladerunner manuals. if you cannot locate, give me a shout.

best

Jeff,

Hi all.. will chime in a bit. Can you show the top edge in that pic? My thought as I looked it.. Is there a THC (Torch Height Controller on this? If the torch drifts up, the deeper downward cutting ability quickly starts to fail. (on mine anyway).. dialing in for 3/4 and such w/ flat plate you can set the initial pierce height, then then any delays on the pierce, then the THC delay starts. (just flat torch cutting). Once that settles and it start moving, THC kicks in. Then it begins to try and maintain the tip voltage.(or what ever it is measuring by drifting up or down. If you cut 2 or more pieces and they look like that... my wager is that it's a parm of some type. Only since I had to fiddle with my rig so many tims on this stuff. If THC is on while doing this, turn it off?

The CandCNC manuals from Tom are a great troublshooting source. even for non CandCNC controllers. his TS approach is very concrete. The 'straight line' cutting tests... you can find them on candcnc.com under manuals. look into the bladerunner manuals. if you cannot locate, give me a shout.

best

Jeff,

This is the top edge of the cut (left side of pic). The THC was off for this cut, having trouble with it lifting during the cut. I thought I had it working last time I used the table did a bunch of the strait line cuts until I had it dialed in. apparently what works for 1/4" doesn't work for 1/2". I ended up making the part on the little cnc mill, it didn't like the 1/2" very much, it dulled the hss bit while I was eating lunch/snoozing and I didn't catch it, tried to rub its way through and work hardened the last cut on 1 feature then started the next feature by work hardening the surface. It wasn't a great day in the shop. fortunately the features were just clearance holes so I just plasmaed them out by hand and got the part done. It's just a fixture to pull a stuck head off of a Fiat engine so it doesn't have to be pretty. I need to study this thing a bit more and get a grasp on why it's not working right, problem is I only seem to have time to work on it when I need something from it.