- Joined

- Nov 5, 2010

- Messages

- 871

I bought a Denford Micromill 2000 this week. This is an English product built around a Sherline mill, using Denso steppers, and all the electronics built into the back of the cabinet. It is made to be used with the proprietary software, which is $675. I don't want to do that.

All I really want at this point to connect it to a PC (RS232) and run some simple software to verify it works. However, I keep running into "Change the servos, toss the Denford board to use a generic breakout board, and run Mach3". I don't really want to double the cost of the machine, knowing it's not much more than a toy anyway.

My question is, why do I need to change the servos, or the board? Do all these machines/servos/boards speak a different language? Am I missing something here?

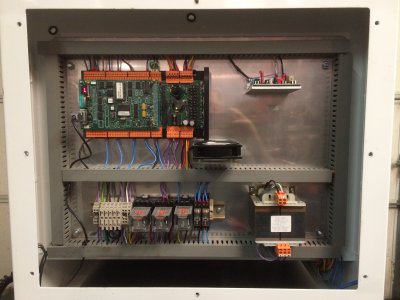

This isn't my mill (first photo). Mine has the high speed air spindle, which I guess is best used for engraving.

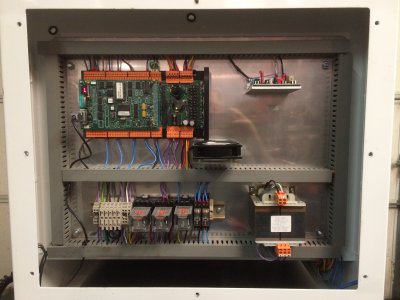

The 2nd photo is the back of my cabinet.

All I really want at this point to connect it to a PC (RS232) and run some simple software to verify it works. However, I keep running into "Change the servos, toss the Denford board to use a generic breakout board, and run Mach3". I don't really want to double the cost of the machine, knowing it's not much more than a toy anyway.

My question is, why do I need to change the servos, or the board? Do all these machines/servos/boards speak a different language? Am I missing something here?

This isn't my mill (first photo). Mine has the high speed air spindle, which I guess is best used for engraving.

The 2nd photo is the back of my cabinet.