- Joined

- Jun 17, 2011

- Messages

- 2,069

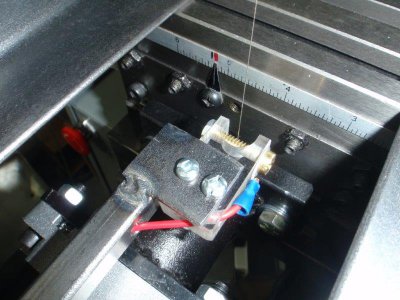

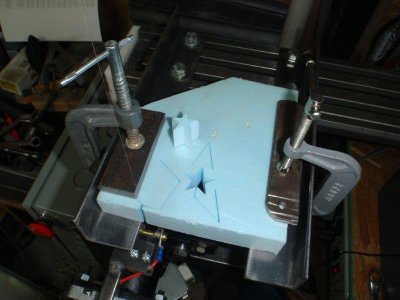

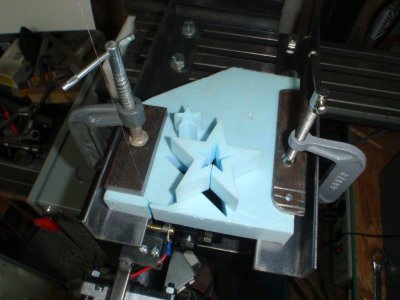

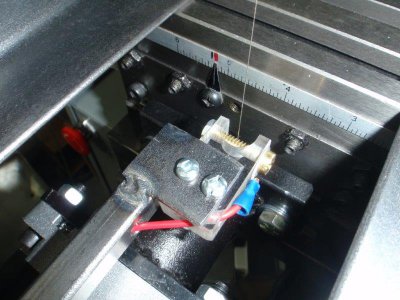

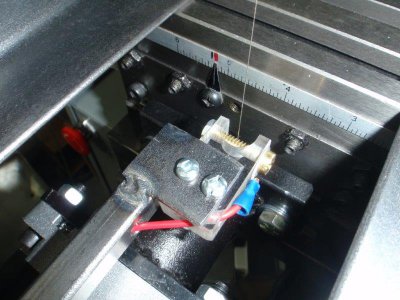

It would seem logical to use CNC to cut foam patterns for lost foam casting. Rather than make a CNC hotwire machine, I opted for a hotwire attachment for the X2 mill conversion. It consists of a frame to hold the wire and a pair of arms attached to the table to move the foam workpiece relative to the wire.

A few years ago, my mother asked me to remove all the electrical parts from an old crock pot she wanted to use as a planter. Lots of good nichrome to last quite a while. The wire is supported by plastic block with brass screws to allow squaring the wire to the table, with a spring to hold some tension on the wire.

I powered the wire with a 12 VAC, 50 VA transformer controlled by a dimmer switch. It cuts quickly and cleanly through a piece of 1" blue foam. I'll think up a shape to program in G-code and give it a try when I have some time.

A few years ago, my mother asked me to remove all the electrical parts from an old crock pot she wanted to use as a planter. Lots of good nichrome to last quite a while. The wire is supported by plastic block with brass screws to allow squaring the wire to the table, with a spring to hold some tension on the wire.

I powered the wire with a 12 VAC, 50 VA transformer controlled by a dimmer switch. It cuts quickly and cleanly through a piece of 1" blue foam. I'll think up a shape to program in G-code and give it a try when I have some time.