- Joined

- Oct 4, 2016

- Messages

- 7,164

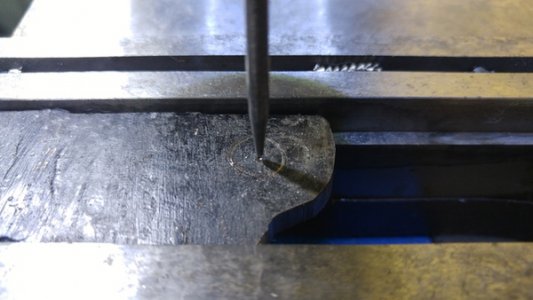

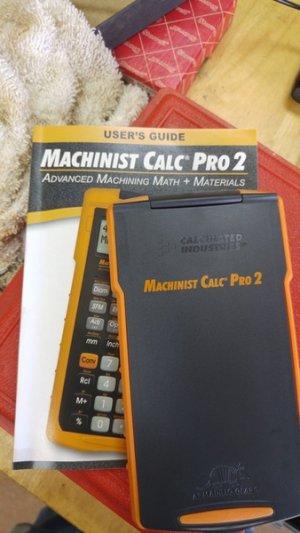

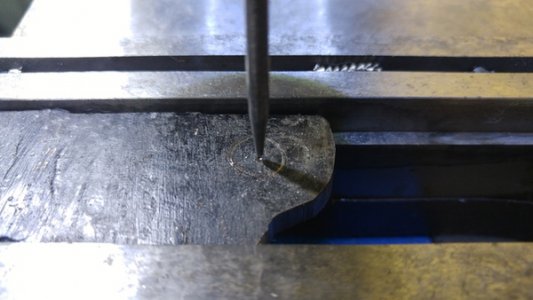

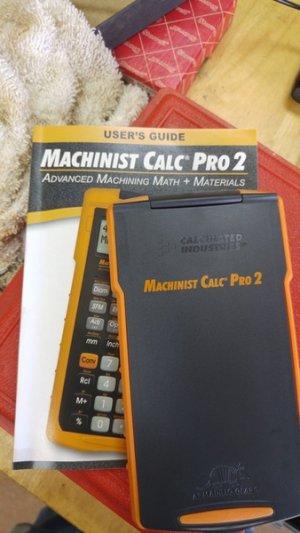

I'm a rookie at machining, so being able to play with some of the gadgets, even though not needed, it's good to practice. I used a new center finder/wiggler for the center punch hole. I got the clutch linkage to clear the header 2.250" top pipe, and bottom pipe today. The top was just a matter of straitening out a bend in the linkage, the bottom was more involved. My first eyeball adjustment came in needing 1 more inch of clearance to get full pedal travel/ release. Reshaped the linkage, and moved the hole for the adjuster, then added a stud ( grade 8 bolt  )with a spring clip hole to use a new left hand, right hand double heim. I'll Get a close measurement tomorrow, cut the CM tubing, and add the threaded ends. Then check to see if I get the right air gap measurements for the pressure plate, and disc .070.

)with a spring clip hole to use a new left hand, right hand double heim. I'll Get a close measurement tomorrow, cut the CM tubing, and add the threaded ends. Then check to see if I get the right air gap measurements for the pressure plate, and disc .070.

Last edited:

Mike

Mike