- Joined

- Feb 23, 2012

- Messages

- 43

Hi All:

A little project for practice as a newbie: Machinists screw jacks.

The left is completed, the right in progress..got a chance to finally use the 3" rotary table to mill the flats I got from HF a while ago.

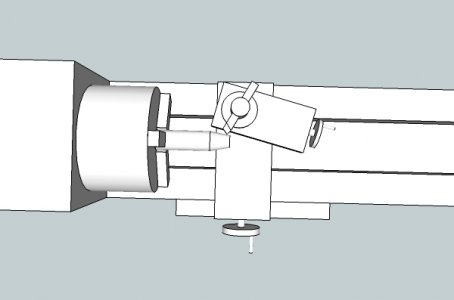

Here is how I set it up, ended up eyeballing the taper as it wasn't critical probably around 5 deg.

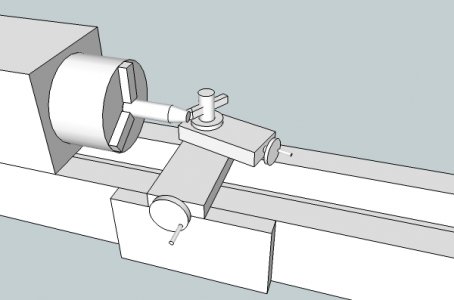

The problem with the clausing is that the degree markings only go up to 90, here is the front view.. the indicator is actually on the back side.. its a real PITA to read, even with the light right on it..

using this setup, how could I dial in an angle > 90? the only idea I have so far is to scribe a mark in the front of the compound, but I have no idea how I would accurately scribe it?

thanks!

Roger

A little project for practice as a newbie: Machinists screw jacks.

The left is completed, the right in progress..got a chance to finally use the 3" rotary table to mill the flats I got from HF a while ago.

Here is how I set it up, ended up eyeballing the taper as it wasn't critical probably around 5 deg.

The problem with the clausing is that the degree markings only go up to 90, here is the front view.. the indicator is actually on the back side.. its a real PITA to read, even with the light right on it..

using this setup, how could I dial in an angle > 90? the only idea I have so far is to scribe a mark in the front of the compound, but I have no idea how I would accurately scribe it?

thanks!

Roger