Nice!

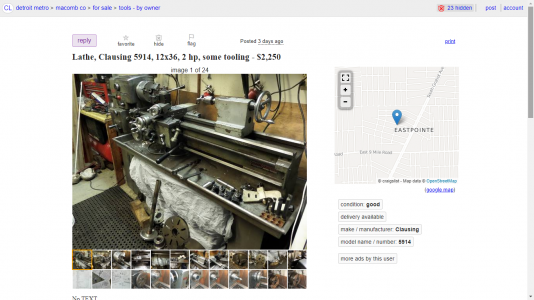

Clausing model 5914 lathe. 1967 vintage. 12 x 36, 12 inch swing (maximum diameter of part that will be able to rotate) by 36 inch between centers. 2 hp. 52 to 2000 rpm. L-00 spindle/chuck mount. Lathe weight is about 1250 lbs. I've owned the machine for just under 20 yrs. I'm upgrading to a larger, heavier lathe. Lathe has power, works well and still in use. Three phase machine - you will either need a static or rotary phase converter or a VFD. Seals in slave cylinder replaced in Sept '20. The lathe is not pristine but it functions well.

Swing Over Bed 12"

Swing Over Cross Slide 7"

Spindle Speeds Back Geared (18) 52 - 280 RPM

Spindle Speeds Belted (18) 360 - 2000 RPM

Feeds Longitudinal (54) 00076" - .0367" / Rev.

Threads English (54) 4 - 192 TPI

Spindle Hole Diameter 1-3/8"

Approximate Overall Dimensions 72" long x 29" wide x 52" H

Flame hardened ways

Lathe comes with: 6 inch Pratt Bunerd Setrite 3-jaw chuck + chuck cradle, 10 inch Elliott 4-jaw chuck + chuck cradle, 10 inch dia face plate, 6 inch dia drive plate, L-00 chuck wrench, follow rest, SPECIAL 4.5MT x 3MT spindle adapter, 3MT dead center, 1/2 inch drill chuck, 5C collet drawbar asm, 27/32 inch 3MT drill bit, quick change tool post with (5) tool holders, brazed carbide tip boring bars, ancient but functional Acurite DRO, carriage micrometer stop, new spare VS belt (old one still very good), electronic and paper copy of the specific user/service manual with exploded parts list. Clausing (in Kalamazo) still supports this lathe.

I made some quick and dirty videos of the lathe under power to give an idea as to how the lathe sounds/operates. Videos of the lathe cutting metal is at times quite shaky and erratic as I am trying to operate the lathe while also holding the camera; drill:

turn with feed:

face with feed:

Quick video of the lathe variable drive system in operation - note the lower end cover and the clutch access cover have both been removed for this video:

Also note while the variable drive works well, the clock spring (part of the variable speed adjuster asm) is broken and the speed is locked-in using a quarter turn (petcock style) valve inline between the master and slave cylinders - valve was in place when I bought the lathe and I never felt the need to splurge for a new clock spring asm. This shut off valve is shown in one of the images.

If you want to see/operate the lathe, you will need to wear a mask that covers both your nose and mouth while in the garage. Depending on how you intend to transport the lathe, I **may** be able to lift the lathe to get it onto your truck or trailer (provided your trailer is not too wide or your truck bed is not too high). Or I can move the lathe in front of a garage door for you to be able to get a flat bed tow truck to access it.

Contact me either by e-mail or phone. If no answer, please leave a VOICE message - I do return calls. No message - no returned call. No TEXT please - I'll never see them.