I picked this up a couple of years ago. It had been owned by the Omaha Public School district, and they guy I bought it from acquired it at an auction from the school district. Overall it was indecent condition. Everything worked, and minimal scars from it's years with the students.

I put a VFD on it for the 3 phase. Nice way to get variable speed from a step pully drive. I set it up to never go below 30hz or over 75hz. Basically 50% to 125%. Too slow and you lose the cooling flow in the motor. Too fast isn't good for a drive train not designed for it. The display and and the speed control are mounted remote so I can reach them. I mounted an e-stop button and the FWD/REV switches for easy reach.

After getting power to it, I proceeded to do a little dismantle and clean up. One gear had a partial chipped tooth. I was able to buy a new one from Clausing (not cheap). The gear is from a slightly newer model which used a different mounting shaft. I made a new shaft to mount the gear. I still have the original gear and shaft. Eventual plan is to repair the chipped tooth someday and offer for sale. Made a new idler gear for the belts. Removed the spindle to replace the belts.

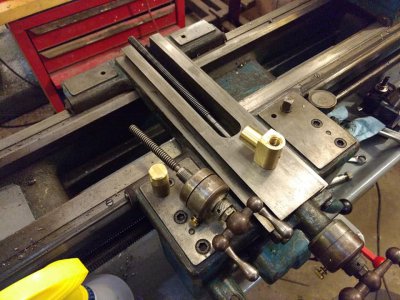

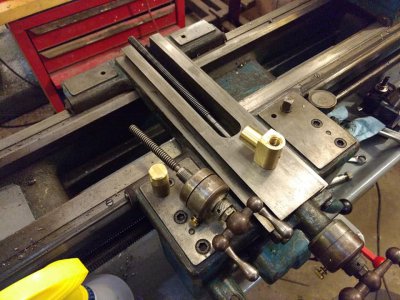

Cleaned up the old 3-jaw chuck, and mounted a new 4-jaw chuck. along the way I found a steady rest for this lathe, and a follow-rest from a 12" Clausing. I made a 3/8" spacer for the follow rest and slotted one mounting hole about 1/4". Now it fits this 12 3/4" swing lathe.

I found a 5C collet closer and shortened it to work on this lathe. Found the correct collet adapter for the spindle (after a couple with the wrong taper). The handwheel on the closer was damaged in shipping, so my brother 3D printed me a new one.

It's been a good learning experience. Still working on the rest of the paint and reattaching the tags.

I put a VFD on it for the 3 phase. Nice way to get variable speed from a step pully drive. I set it up to never go below 30hz or over 75hz. Basically 50% to 125%. Too slow and you lose the cooling flow in the motor. Too fast isn't good for a drive train not designed for it. The display and and the speed control are mounted remote so I can reach them. I mounted an e-stop button and the FWD/REV switches for easy reach.

After getting power to it, I proceeded to do a little dismantle and clean up. One gear had a partial chipped tooth. I was able to buy a new one from Clausing (not cheap). The gear is from a slightly newer model which used a different mounting shaft. I made a new shaft to mount the gear. I still have the original gear and shaft. Eventual plan is to repair the chipped tooth someday and offer for sale. Made a new idler gear for the belts. Removed the spindle to replace the belts.

Cleaned up the old 3-jaw chuck, and mounted a new 4-jaw chuck. along the way I found a steady rest for this lathe, and a follow-rest from a 12" Clausing. I made a 3/8" spacer for the follow rest and slotted one mounting hole about 1/4". Now it fits this 12 3/4" swing lathe.

I found a 5C collet closer and shortened it to work on this lathe. Found the correct collet adapter for the spindle (after a couple with the wrong taper). The handwheel on the closer was damaged in shipping, so my brother 3D printed me a new one.

It's been a good learning experience. Still working on the rest of the paint and reattaching the tags.