Guys,

Thanks for the tips, really helps and nice to know I have a community of machinists who are friendly and willing to read my "new guy" posts and offer your experience!

Nels, thank you for the site!

Now, on with the brake project...

I learned a few more things yesterday after and during the slotting operation.

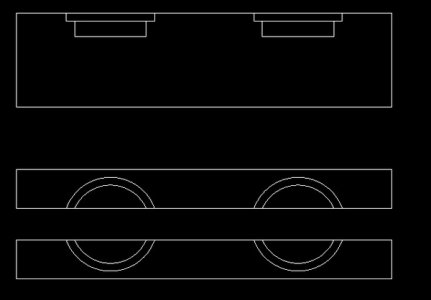

First, I thought it was a great idea to mill the slot for the landing gear leg before the slot in the rotor for the O ring. Well the milled slot made it much harder to hold the part in the lathe chuck. What I should have done was finished the slot for the O ring as before and then use shim stock to support the flange when clamping to the milling table or hold it as described in the post above, or use my 3 jaw on the mill table to hold the part.

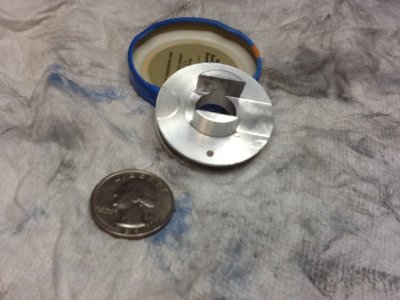

I got one side just about finished. But, I decided the wall thickness of the drums look excessive so I thinned it down so it looked good. Got the slot made with a little bit removed to fit the boss for the trailing link. I think there will be clearance and anti rotation should work ok. But, I forgot that the O ring determines the size of the drum and rotor.

So unless I can find an O ring to fit the bigger drum I'm going to basically start over, again.

One of those moments when I do my Homer Simpson impersonation, Doh! No problem really, I feel like I am learning so many things during the process and I don't mind making another set. Still having a blast!

The O.D. of the new, bigger, hard to find an O ring that size is 1.576"

Jim

I wanted to check and see if I'm headed down the correct path.

I wanted to check and see if I'm headed down the correct path.