I'm guilty of this too but it seems that there are more posts with issues and solving problems than showing off the machines running. I had to modify some front brake spindles/rotors for a prototype job. I had to cut the rotor off and turn the rest of the spindle. This has the opportunity to become a production job which would be cool but messy. Cast iron is not fun because of the dust and mess but I learned I need to wear some long sleeves as my forearms were peppered running these.

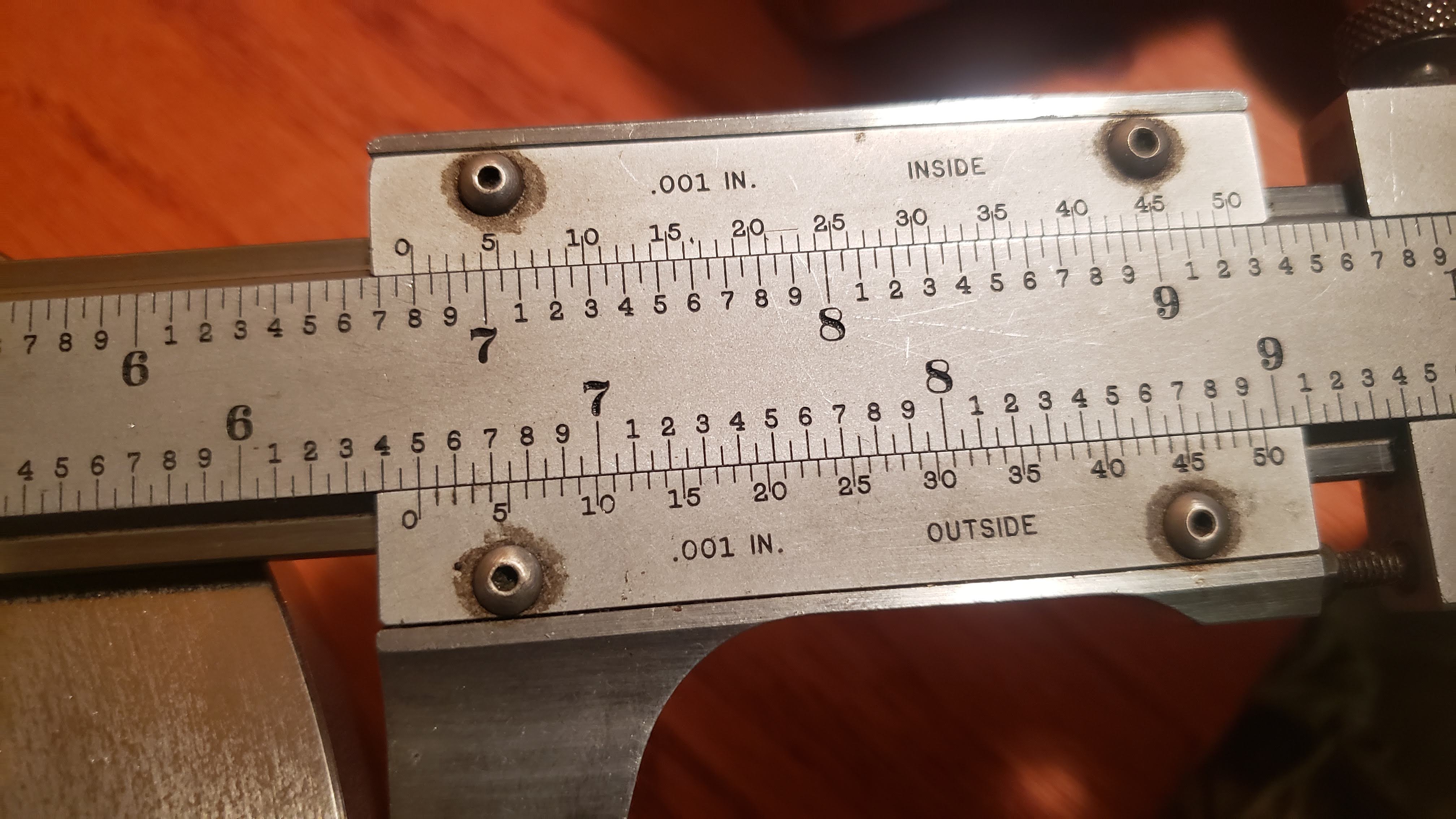

Took a couple of cuts, measured, set the DRO, cut down to .01" above final diameter, measured (was on the money), made finish pass. Switched tools to chamfer, ran part #2 and hit the measurement with no adjustments. This lathe is pretty spot on and I use an Aloris toolpost and holders and I went old school with the vernier. The target was 6.5"

The video is taking .025" DOC (.050" diameter) with the feed on C8 (.011 on the chart). CCMT32.52 Mitsubishi inserts. I finished at 675 rpm and E8 on the feed with a .005" DOC.

Took a couple of cuts, measured, set the DRO, cut down to .01" above final diameter, measured (was on the money), made finish pass. Switched tools to chamfer, ran part #2 and hit the measurement with no adjustments. This lathe is pretty spot on and I use an Aloris toolpost and holders and I went old school with the vernier. The target was 6.5"

The video is taking .025" DOC (.050" diameter) with the feed on C8 (.011 on the chart). CCMT32.52 Mitsubishi inserts. I finished at 675 rpm and E8 on the feed with a .005" DOC.

JK , I love the beam verniers also .

JK , I love the beam verniers also .