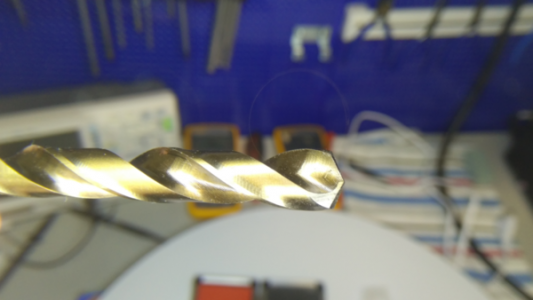

- Joined

- Nov 21, 2012

- Messages

- 793

Well gents, I mentioned in another thread that I was going to order some high-end, Chinese made spiral taps for testing. They arrived today and just for spits and giggles I ordered a bunch of dies as well. This is just a quick visual report on them before I set up some proper testing.

Typical to Chinese manufacturers, they packaged the taps into dodgy aluminium cases that I will immediately throw away.

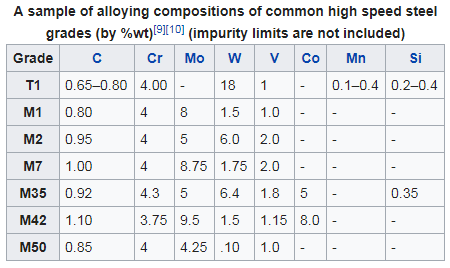

The taps on the left are made from M35 HSS which was the cheaper option. These came in at about $3,75 per tap. According to the table below the HSS contains about 5% cobalt. The origin of the alloy is Japan.

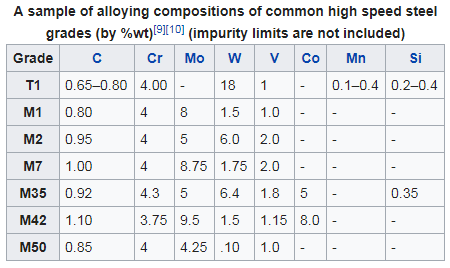

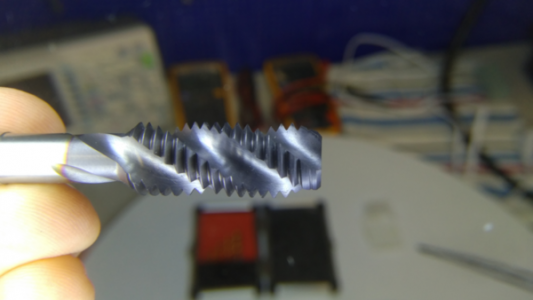

The grinding on the taps looks quite good. I am not sure about the quality of the TiN coating, however the manufacturer is a major supplier to the major machining and manufacturing centers in China so it should be OK. Here are some closer images:

As you can see, despite the packaging, the taps look very good. No dags or burrs at all and the individual teeth are very consistent and sharp.

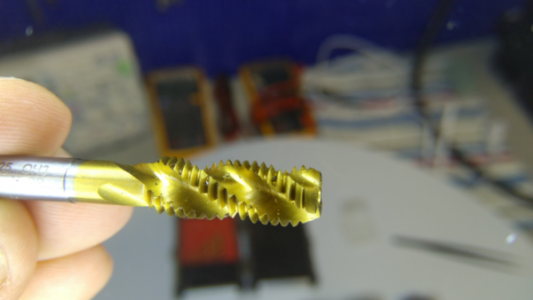

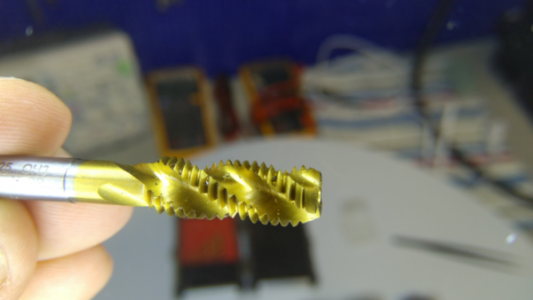

Now lets have a look at the M42 taps.

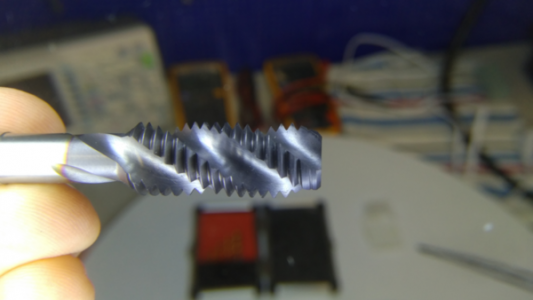

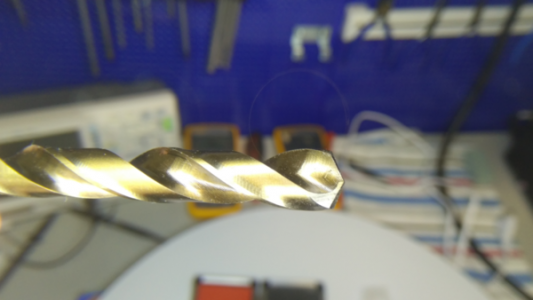

The M42 HSS has 8% cobalt and is the manufacturers premium offering. They came in at $9,75 per tap on average (including the drill bit also in M42). They are TiAlN coated and the coating seems to be on par with German taps I have used. Strangely, the grinding seems to be more refined on these taps as if the spirals were ground in smaller increments as there are nearly no facets visible in the helix. I ordered these with the applicably sized drill bits and the drills are very well made as well and the grinding job is superb:

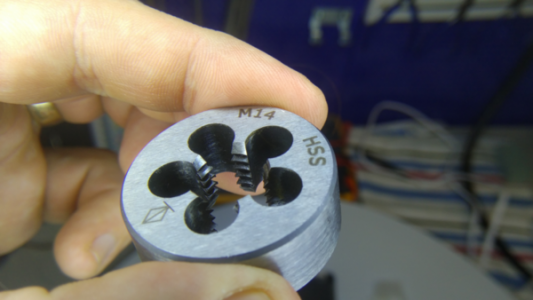

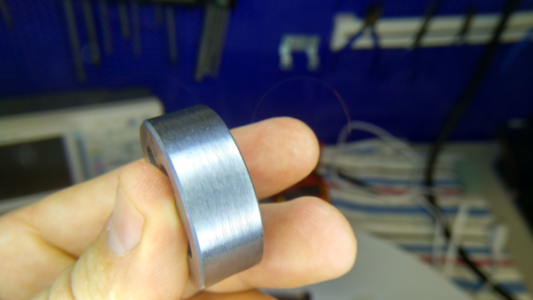

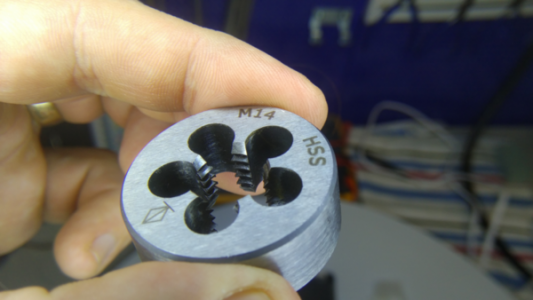

So last but not least we have the dies. These are made from M35 and cost $4,45 on average.

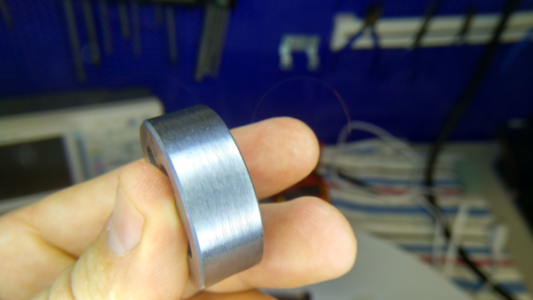

The image below shows the quality of the cylindrical surfaces - certainly not as high as my Swedish dies.

The teeth are very sharp on the larger dies but from M4 and down, there are very small burrs on the taper leading to the cutting teeth. These were not an issue to remove with small tweezers so are likely not going to cause problems during operation as they will likely wipe away:

Tomorrow I am hoping to give these a run through some material and see how they cut and the quality of the threads they leave behind. Stay tuned.

Paul.

Typical to Chinese manufacturers, they packaged the taps into dodgy aluminium cases that I will immediately throw away.

The taps on the left are made from M35 HSS which was the cheaper option. These came in at about $3,75 per tap. According to the table below the HSS contains about 5% cobalt. The origin of the alloy is Japan.

The grinding on the taps looks quite good. I am not sure about the quality of the TiN coating, however the manufacturer is a major supplier to the major machining and manufacturing centers in China so it should be OK. Here are some closer images:

As you can see, despite the packaging, the taps look very good. No dags or burrs at all and the individual teeth are very consistent and sharp.

Now lets have a look at the M42 taps.

The M42 HSS has 8% cobalt and is the manufacturers premium offering. They came in at $9,75 per tap on average (including the drill bit also in M42). They are TiAlN coated and the coating seems to be on par with German taps I have used. Strangely, the grinding seems to be more refined on these taps as if the spirals were ground in smaller increments as there are nearly no facets visible in the helix. I ordered these with the applicably sized drill bits and the drills are very well made as well and the grinding job is superb:

So last but not least we have the dies. These are made from M35 and cost $4,45 on average.

The image below shows the quality of the cylindrical surfaces - certainly not as high as my Swedish dies.

The teeth are very sharp on the larger dies but from M4 and down, there are very small burrs on the taper leading to the cutting teeth. These were not an issue to remove with small tweezers so are likely not going to cause problems during operation as they will likely wipe away:

Tomorrow I am hoping to give these a run through some material and see how they cut and the quality of the threads they leave behind. Stay tuned.

Paul.