- Joined

- Oct 30, 2019

- Messages

- 225

At an auction last year I picked up some grab-bag vises for $35/ea. I didn't get to pick which vise I wanted, it was just random assignment from a crate of used-tool-overstock, the same place I got the crate of portable bandsaws from.

One of the vises I brought home looked like a no-name combination mechanic/pipe vise, which I thought would be great on our welding table due to the multiple degrees of freedom it offers. This would also let me retire/repurpose a nicer USA-made Mac Tools/Wilton vise that had originally been on there.

Started with a bit of cleanup to remove layers of gunk and heavy paint, mainly hitting it with the needle scaler to blast off layer of old paint, cleaning, lubricating and reassembling.

There were some parts missing that retained the spindle, I improvised solutions to that for now but will have a future separate thread when I make a proper end cap.

A couple quick coats of paint later, I thought this was ready for use

but then on first use, failure without cranking down at all hard on the spindle

My theory is that this vise was dropped at some point when being stored or moved around prior to sale. There must have been a pretty significant crack started, which propagated as soon as I put any force on it.

Even though this is a no-name vise, it would meet my purposes great and of course I had already welded the mounting holes for the previous vise on the table... so I wanted to fix this somehow.

I put the slide into the lathe (sorry no pics) and very sketchily (no tail support, lots of chatter) turned a bevel on the end. I took one quick attempt at nickel welding this but immediately could tell that was not going to work without more time and care given to beveling the slide piece -- and I did not think it was the right direction to go

I ended up buying my first oxyacetylene setup, with the intent of brazing this together. I noticed that the spindle could clamp the pieces nicely along their fracture line, and the bevel should give decent cross-section for the braze -- if I can get enough preheat...

I removed the jaw inserts from the sliding jaw, and reproduced this clamping with some threaded rod+nuts+washers to avoid exposing the spindle to significant heat.

So at this point in the story, I'm going to gloss over two failed brazing attempts. I tried preheating with a rosebud, but was unsuccessful at getting good wetting of the parts - it cracked upon mild testing. I was being cautious with the duration of my rosebud usage because even for my modest rosebud, for safe acetylene consumption at that rate I would need a full-size tank, or possibly even two with a manifold.

The second attempt was similar, but I preheated with rosebud and focused heat with a #3 brazing tip (my largest) to try and heat as deeply as possible. This was also unsuccessful, due to the mass of the moving-jaw portion of the repair.

At this point I knew I needed drastically more preheat. Of course there is the BBQ grill approach - but I wanted to go about as hot as possible, without warping/damaging my grill by running at max heat for hours (and/or running out of propane).

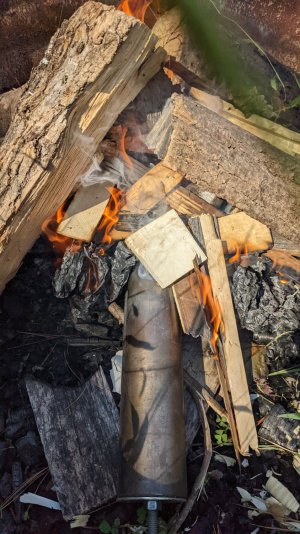

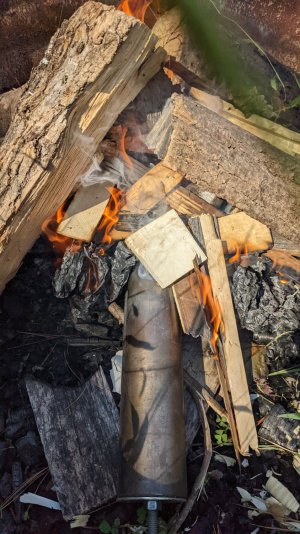

I went low-tech ... built a campfire over/around the parts, with the threaded rod clamping them together in the desired mating position. The "clocking" of the slide and jaw relative to each other is critical, I figured this would be impossible to align while the parts are 500-700F, and when the clock is ticking on the parts cooling down.

Started the fire and kept feeding wood in for about 60 minutes. I let it burn down for another 30 minutes, ending with the part assembly sitting in a bed of hot coals

To pull it out of the fire, the protruding threaded rod came in handy - I had pre-formed a bail out of mechanics wire, to hook both ends and lift it out.

On a fiberglass blanket, which I wrapped closed while wheeling the part to the shop on a metal cart.

I don't have pictures of the brazing process due to PPE and keeping pace to avoid losing the preheat. Put it in a bucket of sand and let it cool down overnight.

The next morning I test fit the part in the vise to confirm no warping or damage; and installed the spindle temporarily to see if it would immediately crack when clamping a block of wood (it didn't, but I also didn't push my luck)

Now to try and clean the braze up some, particularly because it interfered with the slide's operation. I could take an angle grinder to this, and/or files, and/or a pneumatic belt grinder .... all of those are manual, probably imprecise, and won't give the most uniform output.

Ideally I would turn the buildup down in the lathe. However my working lathe is a Logan 200, and I definitely would want tail support since I need to work very far away from the jaws. The slide is about 12" long.

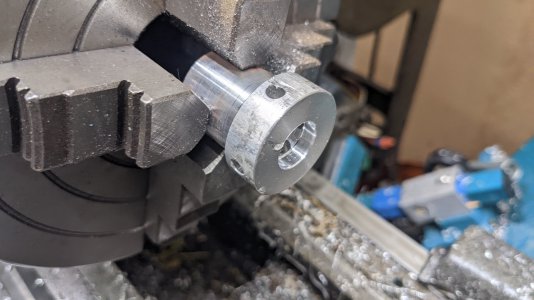

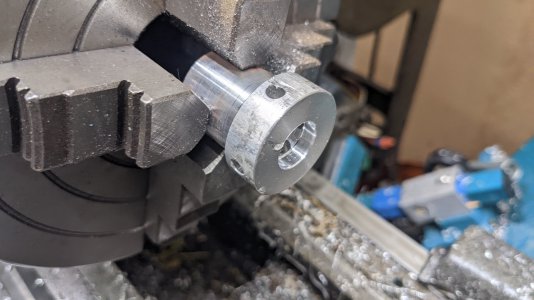

To accomplish this, I spot-checked.... it looks like the spindle bore is concentric with the OD of the slide. My goal, then, was to use the spindle bore with a live center in the tailstock, but I needed a bushing to reduce the diameter

I happened to have an aluminum off-cut that was the right length, and already had a shoulder in it. I just turned down the minor diameter for a tight sliding fit in the spindle bore; flipped it around in the 4-jaw chuck, and cleaned up an existing through hole with the boring bar to ensure concentricity since this is where the live center will mate.

It worked..... enough clearance above the lathe bed, but I had to keep the carriage away.

After fussing with the exact toolpost rotation and positioning, I set the compound up for a 45 degree chamfer (to reduce stress risers), withdrew the compound back as far as it would go, and set a stop on the bed/ways to ensure the carriage would not go further and allow any part of the carriage or toolholding to collide with the rotating part.

I did not have any long HSS blanks to make a tool out of, so I proceeded very slowly into the interrupted cut with hobby-grade insert tooling

After turning the bulk of the material off, I spun the part slowly in the lathe while using a pneumatic finger grinder to blend and polish the remaining braze. This was necessary to clean the slide up for proper fitment in the fixed jaw/base of the vise.

After some paint and reassembly, I now have my weld positioner back. I will not under any circumstances use this for heavy clamping/violence as I do not want to repeat the repair - but I think it came out well enough. There are a bunch of voids, but I do not think it is worth going through the repair again unless it breaks.

Pretty happy with this as my first-ever braze repair. Also if you factor in the capital cost of my oxyfuel setup... this is probably one of the most expensive import combination vises in use by anyone today!

As always, thanks for reading

One of the vises I brought home looked like a no-name combination mechanic/pipe vise, which I thought would be great on our welding table due to the multiple degrees of freedom it offers. This would also let me retire/repurpose a nicer USA-made Mac Tools/Wilton vise that had originally been on there.

Started with a bit of cleanup to remove layers of gunk and heavy paint, mainly hitting it with the needle scaler to blast off layer of old paint, cleaning, lubricating and reassembling.

There were some parts missing that retained the spindle, I improvised solutions to that for now but will have a future separate thread when I make a proper end cap.

A couple quick coats of paint later, I thought this was ready for use

but then on first use, failure without cranking down at all hard on the spindle

My theory is that this vise was dropped at some point when being stored or moved around prior to sale. There must have been a pretty significant crack started, which propagated as soon as I put any force on it.

Even though this is a no-name vise, it would meet my purposes great and of course I had already welded the mounting holes for the previous vise on the table... so I wanted to fix this somehow.

I put the slide into the lathe (sorry no pics) and very sketchily (no tail support, lots of chatter) turned a bevel on the end. I took one quick attempt at nickel welding this but immediately could tell that was not going to work without more time and care given to beveling the slide piece -- and I did not think it was the right direction to go

I ended up buying my first oxyacetylene setup, with the intent of brazing this together. I noticed that the spindle could clamp the pieces nicely along their fracture line, and the bevel should give decent cross-section for the braze -- if I can get enough preheat...

I removed the jaw inserts from the sliding jaw, and reproduced this clamping with some threaded rod+nuts+washers to avoid exposing the spindle to significant heat.

So at this point in the story, I'm going to gloss over two failed brazing attempts. I tried preheating with a rosebud, but was unsuccessful at getting good wetting of the parts - it cracked upon mild testing. I was being cautious with the duration of my rosebud usage because even for my modest rosebud, for safe acetylene consumption at that rate I would need a full-size tank, or possibly even two with a manifold.

The second attempt was similar, but I preheated with rosebud and focused heat with a #3 brazing tip (my largest) to try and heat as deeply as possible. This was also unsuccessful, due to the mass of the moving-jaw portion of the repair.

At this point I knew I needed drastically more preheat. Of course there is the BBQ grill approach - but I wanted to go about as hot as possible, without warping/damaging my grill by running at max heat for hours (and/or running out of propane).

I went low-tech ... built a campfire over/around the parts, with the threaded rod clamping them together in the desired mating position. The "clocking" of the slide and jaw relative to each other is critical, I figured this would be impossible to align while the parts are 500-700F, and when the clock is ticking on the parts cooling down.

Started the fire and kept feeding wood in for about 60 minutes. I let it burn down for another 30 minutes, ending with the part assembly sitting in a bed of hot coals

To pull it out of the fire, the protruding threaded rod came in handy - I had pre-formed a bail out of mechanics wire, to hook both ends and lift it out.

On a fiberglass blanket, which I wrapped closed while wheeling the part to the shop on a metal cart.

I don't have pictures of the brazing process due to PPE and keeping pace to avoid losing the preheat. Put it in a bucket of sand and let it cool down overnight.

The next morning I test fit the part in the vise to confirm no warping or damage; and installed the spindle temporarily to see if it would immediately crack when clamping a block of wood (it didn't, but I also didn't push my luck)

Now to try and clean the braze up some, particularly because it interfered with the slide's operation. I could take an angle grinder to this, and/or files, and/or a pneumatic belt grinder .... all of those are manual, probably imprecise, and won't give the most uniform output.

Ideally I would turn the buildup down in the lathe. However my working lathe is a Logan 200, and I definitely would want tail support since I need to work very far away from the jaws. The slide is about 12" long.

To accomplish this, I spot-checked.... it looks like the spindle bore is concentric with the OD of the slide. My goal, then, was to use the spindle bore with a live center in the tailstock, but I needed a bushing to reduce the diameter

I happened to have an aluminum off-cut that was the right length, and already had a shoulder in it. I just turned down the minor diameter for a tight sliding fit in the spindle bore; flipped it around in the 4-jaw chuck, and cleaned up an existing through hole with the boring bar to ensure concentricity since this is where the live center will mate.

It worked..... enough clearance above the lathe bed, but I had to keep the carriage away.

After fussing with the exact toolpost rotation and positioning, I set the compound up for a 45 degree chamfer (to reduce stress risers), withdrew the compound back as far as it would go, and set a stop on the bed/ways to ensure the carriage would not go further and allow any part of the carriage or toolholding to collide with the rotating part.

I did not have any long HSS blanks to make a tool out of, so I proceeded very slowly into the interrupted cut with hobby-grade insert tooling

After turning the bulk of the material off, I spun the part slowly in the lathe while using a pneumatic finger grinder to blend and polish the remaining braze. This was necessary to clean the slide up for proper fitment in the fixed jaw/base of the vise.

After some paint and reassembly, I now have my weld positioner back. I will not under any circumstances use this for heavy clamping/violence as I do not want to repeat the repair - but I think it came out well enough. There are a bunch of voids, but I do not think it is worth going through the repair again unless it breaks.

Pretty happy with this as my first-ever braze repair. Also if you factor in the capital cost of my oxyfuel setup... this is probably one of the most expensive import combination vises in use by anyone today!

As always, thanks for reading

Last edited: