I'm guessing you mean the ends of the square stock, and not the edges of the square stock (the square faces, not the rectangular ones). I'm also guessing that you'll be turning the part on the lathe, either in a 4 jaw chuck or in a square collet.

Looks like a darn good excuse to grind yourself a form tool.

If you're not terribly picky about how perfectly rounded the chamfer has to be, you could free-hand grind a lathe tool to the proper shape.

Or, if you have some non-hardened square tool steel, clamp it in the vice and use and endmill of the desired curve diameter to cut the curve. Grind your reliefs (tilting the workpiece a couple of degrees so the endmill cuts a slanted hole in it is a lot more accurate and faster), then harden, temper, and hone. Being brass, you can get away with no rake. Make sure you got a good hold on that tool in the toolpost. Form tools tend to want to chatter like *CRAZY*

If that doesn't work for you, you can grab a corner-rounding endmill in the toolpost and use it like a form tool. In a pinch, you can use a carbide router bit instead of the endmill. I'd be a little leery of the interrupted cut on a carbide tool, but it is brass, and a small effective diameter, so I wouldn't think chipping would be as big of an issue as it would with steel.

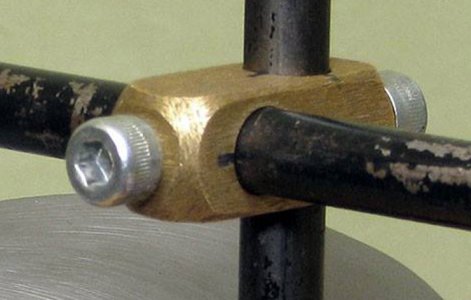

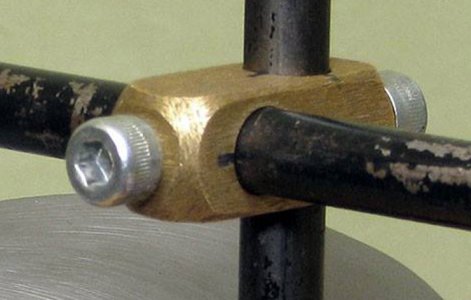

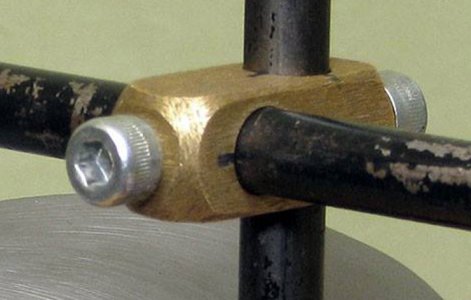

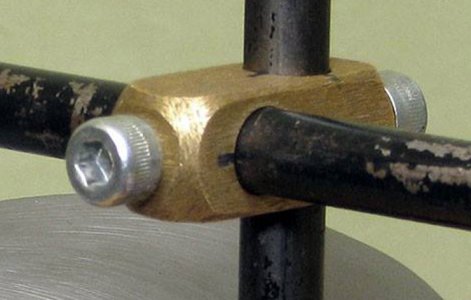

A ball turning jig is another option.

And last but not least, a belt sander would do it pretty darn fast too.

But it'd be prettier if you use a form tool of some sort.