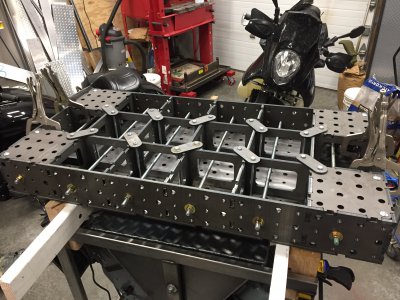

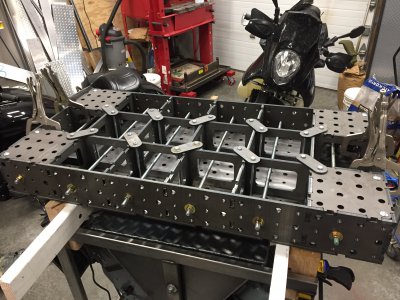

Recently finished putting together a 24"x48" Certiflat Fab Block table. Pretty happy with the quality of material, and fit. Clamped the daylights out of it before tacking it together, and tacked it all the way around before finish welding. Worth the effort IMO, as the largest gap I could find using a straight edge( it's spec'd at .003") was .010". I went with the 3/8" thick option, as 1/4" seemed kinda thin to me for using clamps in the 16mm holes. Also went with the alternating 16mm holes and tapped 1/2-13. Made the mobile base with some scrapped battery stands from work. Added leveling pads, to fine tune the top, and compensate for my uneven shop floor. Haven't played with it yet, to see how much it twists/warps due to uneven leg adjustment. I'm sure it will get out of whack some. Going to be used for layout, fixturing, and TIG welding only. For MIG and stick, it will get covered with a 14ga topper. Look forward to trying it out, once work slows down a bit.