I would like to share a setup I came up with that could perhaps help folks without one. (On a Sherline it'd be quite a project to make use of one even if you had it.)

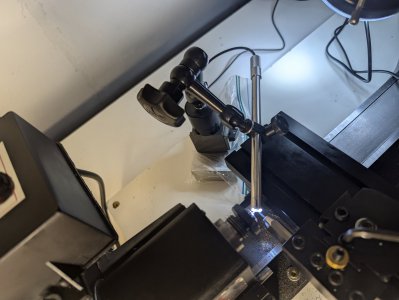

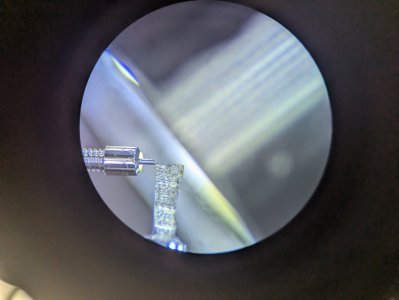

The little silver stick is an "otoscope" from Amazon that was I think $25-30. It can send images to phone or computer. I filed off most of the metal guard in front of it so I can get it as close as its optical system allows. It happened to be exactly the right diameter to fit into the indicator holder.

Since Sherline is mostly aluminum, the indicator holder sits on a 1-2-3 block on a table next to the lathe. (By the way, I splurged on a Noga mini-indicator-holder which happens to be just the right size to sit in the indentation in the middle of the (steel) ways on Sherline, without touching the machined surfaces, so I could probably use it that way, but the 123 block is easier to move around, and fixed position is not needed in this application.)

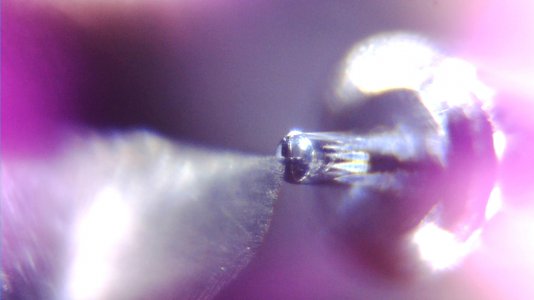

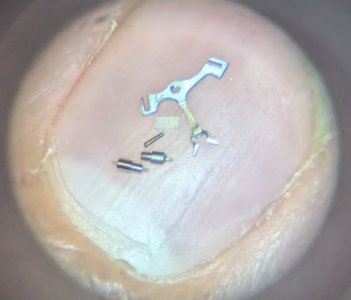

That freshly made (so exactly centered) pinion in the third image is just under 120 microns so (even accounting for parallax issues) I feel reasonably confident that the cutter is within 10 microns of center.

Very best,

-Pavel

The little silver stick is an "otoscope" from Amazon that was I think $25-30. It can send images to phone or computer. I filed off most of the metal guard in front of it so I can get it as close as its optical system allows. It happened to be exactly the right diameter to fit into the indicator holder.

Since Sherline is mostly aluminum, the indicator holder sits on a 1-2-3 block on a table next to the lathe. (By the way, I splurged on a Noga mini-indicator-holder which happens to be just the right size to sit in the indentation in the middle of the (steel) ways on Sherline, without touching the machined surfaces, so I could probably use it that way, but the 123 block is easier to move around, and fixed position is not needed in this application.)

That freshly made (so exactly centered) pinion in the third image is just under 120 microns so (even accounting for parallax issues) I feel reasonably confident that the cutter is within 10 microns of center.

Very best,

-Pavel