- Joined

- Feb 7, 2013

- Messages

- 2,534

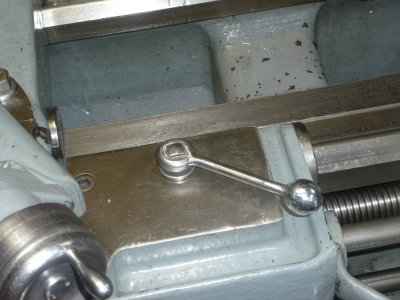

This morning's project was to make a handle for the carriage lock on the Monarch. It's all pretty straight forward

not needing too much explanation, just some shop time with the lathe and mill and a little acetylene welding.

Filing the square piece to fit the locking bolt took a bit of time for a nice fit. I used a piece of a hardened 3/8 inch injector pin

for the handle and the ball was turned starting with a square chunk of aluminum. I have had luck in the past threading

injector pins but not this time. I welded on some 3/8 inch threads to the end of the injector pin since I couldn't see any other

way to accomplish the task. I had picked up along the road a box of coat hangers that is just the ticket for acetylene welding

or TIG welding. It's hard to pass by free welding rods!

The handle is also handy to get an idea of the wear on the lathe ways. If you set a slight tension at the head stock end and then run the carriage to the tail stock end and note the position, one can get a rough idea as to how much wear is on the ways. It's easy to measure

the wear if you know the pitch of the hold down bolt and the degree of angularity change on the handle. I noted some wear, about what

I had expected from an old lathe.

not needing too much explanation, just some shop time with the lathe and mill and a little acetylene welding.

Filing the square piece to fit the locking bolt took a bit of time for a nice fit. I used a piece of a hardened 3/8 inch injector pin

for the handle and the ball was turned starting with a square chunk of aluminum. I have had luck in the past threading

injector pins but not this time. I welded on some 3/8 inch threads to the end of the injector pin since I couldn't see any other

way to accomplish the task. I had picked up along the road a box of coat hangers that is just the ticket for acetylene welding

or TIG welding. It's hard to pass by free welding rods!

The handle is also handy to get an idea of the wear on the lathe ways. If you set a slight tension at the head stock end and then run the carriage to the tail stock end and note the position, one can get a rough idea as to how much wear is on the ways. It's easy to measure

the wear if you know the pitch of the hold down bolt and the degree of angularity change on the handle. I noted some wear, about what

I had expected from an old lathe.