- Joined

- Jan 25, 2022

- Messages

- 129

I had some TCMT and CCMT tools lying around, largely unused till now. I tested them on a piece of 1.5" 1045.

No real questions here. Just newbie observations. Comments welcome, of course.

Using the speed/feed tables, 1045 needs about 800 SFM with carbide. So, at 1.5" - 2100 RPM, which exceeds the max speed of my lathe, so I set RPM to 1800. Feed rate is 0.0025"/rev. Even at that feed rate, things happened really fast.

Are there lathes that actually spin near 6000 RPM for a 0.5" piece of stock?

Are there lathes that actually spin near 6000 RPM for a 0.5" piece of stock?

I ran various DOCs, up to 0.1"+. The lathe (PM1130) didn't struggle at all at 0.1", and probably could go deeper.

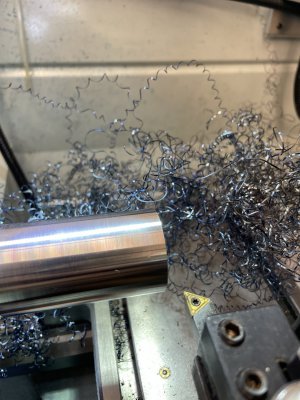

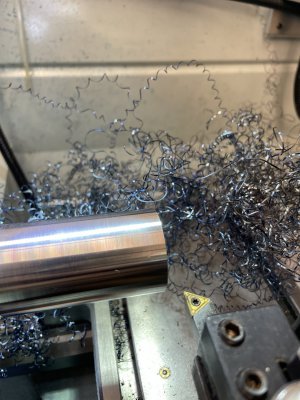

Images are TCMT at left, CCMT center. DOC was 0.030 here. I was surprised at TCMT finish quality (appearance-wise). That finish was pretty consistent at most DOC, though randomly it would go south - badly. Not sure why. Wondering if a previous cut had work-hardened the surface -- and a deeper DOC was required?

CCMT insert performance was similar but seemed to have a lot of light surface tearing even with a 'good' finish.

Blue chips in most cases but bad chip management -- bird nests, long streamers, etc. I could get good chip breaking only at certain DOCs, with no apparent pattern.

As the diameter got down below 1", the reduction in surface speed (given lathe max RPM) seemed to affect the finish.

Finally, I tried one of my HSS tools at higher speeds/feeds just to see. Tool tip became annealed about half-way in, then quickly wore off.

Might do a similar test on 1215, though will probably start using more carbide -- at least for roughing cuts.

No real questions here. Just newbie observations. Comments welcome, of course.

Using the speed/feed tables, 1045 needs about 800 SFM with carbide. So, at 1.5" - 2100 RPM, which exceeds the max speed of my lathe, so I set RPM to 1800. Feed rate is 0.0025"/rev. Even at that feed rate, things happened really fast.

I ran various DOCs, up to 0.1"+. The lathe (PM1130) didn't struggle at all at 0.1", and probably could go deeper.

Images are TCMT at left, CCMT center. DOC was 0.030 here. I was surprised at TCMT finish quality (appearance-wise). That finish was pretty consistent at most DOC, though randomly it would go south - badly. Not sure why. Wondering if a previous cut had work-hardened the surface -- and a deeper DOC was required?

CCMT insert performance was similar but seemed to have a lot of light surface tearing even with a 'good' finish.

Blue chips in most cases but bad chip management -- bird nests, long streamers, etc. I could get good chip breaking only at certain DOCs, with no apparent pattern.

As the diameter got down below 1", the reduction in surface speed (given lathe max RPM) seemed to affect the finish.

Finally, I tried one of my HSS tools at higher speeds/feeds just to see. Tool tip became annealed about half-way in, then quickly wore off.

Might do a similar test on 1215, though will probably start using more carbide -- at least for roughing cuts.