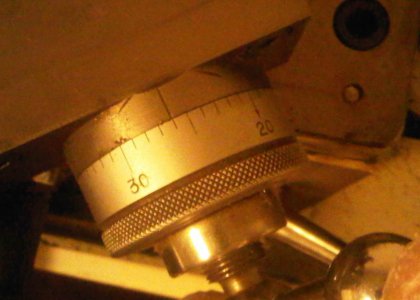

Cross slide backlash could be caused by wear in the cross feed screw,wear in the cross feed nut, THE NUT COULD BE LOOSE. In the top of the cross slide,you can see the top of the bolt that holds the brass nut below. Crank the slide in and out,and see if the head of that bolt moves at all. A 4th. backlash could be that there is looseness in the crank handle region,where the nut that adjusts the snugness of the cross slide(which rides on thrust bearings in this lathe,a nice feature, needs to be tightened a bit. You need to take the balcrank handle off,remove the nut that holds the dials on,remove the dials,and inside you'll see another nut that tightens the cross feed screw against the thrust bearings. By the way,I like those balcrank handles. Most lathes these days do not have them. Balcrank is the name of a "balanced crank" handle patented in the 19th.C.. The ball is supposed to balance the handle so the handle doesn't revolve by itself from vibration. Most balcranks aren't properly balanced anyway,though.

More likely than anything is that the cross feed screw or nut has gotten worn. I have seen old lathes where the acme threads of the cross feed have gotten so worn,the threads look like knife blades rather than acme threads.

In this event,I'd use the lathe to turn a new cross feed screw,and attach it to the front end of the original cross feed screw,where there is a small gear for engaging the power feed gear coming from the apron. As for the nut,I have made Acme thread taps,but that may be beyond you as of yet. Backlash does exist in all screw adjusted lathes,though,and it really isn't a problem if you know how to deal with it,as I've mentioned.

This older lathe will have been made in TAIWAN,NOT CHINA,which is a BIG BOOST in quality.

I wish I hadn't sold my 1024,but I needed the money to put towards my 16" X 40". The 16" is a gear head lathe,which doesn't make as smooth a finish as a belt fed lathe(unless you have a super expensive lathe). Gear heads leave traces of the gears meshing on the surfaces you are turning. Plus,my 16" lathe doesn't have the range of threading that the 1024 had(though I can alter that by replacing gears.

P.S.: Your lathe has a carriage that you can put oil into,a great advantage. Don't overfill it,or the oil will overflow into the chip pan. You'll soon discover how much oil it takes. There may be no sight glass on that lathe for the carriage. I'm not sure if I see one. Mine didn't have one if I recall,but it's been since 1986.