- Joined

- Sep 22, 2010

- Messages

- 7,222

Re-Posted with permission of the author Mick Finch

Original at : http://bluechipmachineshop.com/bc_blog/rebuilding-a-burke-1-horizontal-milling-machine/

Rebuilding a United States Machine Tool Co. #1 Horizontal Milling Machine

Posted by mick on September 25, 2011

This entry is to document the disassembly, cleaning and overhaul of a Burke No. 1 Horizontal Mill purchased on 9/24/2011, its bound to be a lengthy process, bear with me.

The story starts with a friend (we’ll call him “Steve”), sending an Email to the CAMS group with a list of the goodies he’ll have for sale at the 2011 CAMS Yard Sale. One item that interested me was a Van Norman 1R mill, and I inquired about it. It turned out to be more mill than I needed, and I told him I was really looking for a dedicated horizontal mill, without all the bells and whistles; a “crab”. At this point he mentions the old Burke might be what I’m looking for. Fully operational, ugly, and cheap, I’m hooked. Steve is a crafty individual; He knows if its ugly and cheap, I’ll probably be interested. He asked me (after the money changed hands) “Did you feel it when I set the hook?”. Frankly, I never saw it coming. All kidding aside; Thanks for the great deal, Steve. This is the sight that greeted me when I arrived at the Stallings Institute of Industrial Antiquities:

The pics don’t really show just how dirty and ugly this thing is, you have to see it up close. Its saving grace is that it is fully functional and complete, except for a couple of hand wheels. It moves smoothly, and it appears that everything works. You can get filthy just standing next to it.

This is a shot of the movable head (counterbalanced by a weight inside the base). It is a Browne & Sharp #9 taper, and an arbor is included in the sale.

This is the table rack. This will give you an idea of the clean up in store for me. The mill is a “hand mill”, meaning there is no power feed; the table is advanced with a lever on a rack and pinion arrangement.

Heres a shot of the back (shooting into the light), showing the pulley arrangement; a very stout affair.

And a shot of the pulleys. A very solid setup.

Here’s the motor, a 220V Century. You can see the motor mount on this mill is pretty substantial. The motor and mount probably weigh 100 Lbs.

I haven’t taken delivery of the mill yet (scheduled for Oct 1), but I’m anxious to get started on the overhaul. I don’t plan on making it a museum piece, but want something that doesn’t make you cringe to look at it. Right now it looks like it fell out of the Ugly Tree, and hit every branch on the way down. More importantly, I want everything on the mill to function smoothly, and accurately. The best way I know to do this is to get the thing apart and see whats broken/worn/rusty.

I have high hopes for this, based on its overall condition (look beyond the paint and grease), its a nice heavy machine, and should be fun to work on.

***UPDATE***

Well, it didn’t take long for somebody to correct me; Irby on the Yahoo Burke site informed me that this is actually a United States Machine Tool Company mill, built prior to the merger of USMT Co. and Burke in the mid 60′s. Thanks Irby.

More later……….

ONE WEEK LATER:

Heres the main column sitting in the driveway, ready for a clean-up (REALLY ready).

This is after the first of four treatments of Easy-Off oven cleaner. Spray it on, and let it sit for 10-15 minutes. The years of caked on dried oil and swarf just fly off when you hit it with a pressure washer.

Heres a shot of the back side, after 3 treatments of oven cleaner. The old paint just kinda dissolves (there was about 4 coats). The prime coat is somewhat more stubborn, and will probably remain on for posterity.

This is the front side, and is pretty much down to bare metal, and ready for paint. Once that is done, I can start hanging parts, (yet to be stripped). Once I get the base placed in the shop, I plan on rebuilding the larger parts first. This means working my way from bottom to top, with the last part to be done: the spindle head. This will allow me a little time to locate bearings and seals, as this is the only area of the mill that is even a bit “iffy”. Nothing really drastic, but with the head laying on my steel bench, a slight “rumble” showed its self. I haven’t had time to investigate, and I suspect it might just be the noise being amplified by the bench. We’ll see.

Heres some of the swarf and dried oil thats plastered all over this machine. It doesn’t come off easily, oven cleaner is the easiest way I’ve found.

It took me an hour or two to find the serial number (9365 R). Its on the front edge of the knee.

This is the only tag I found identifying it as ” Mfd by U.S. Machine Tool Co. Cincinnati, Ohio”. This was on the bottom of the spindle head. Lots more swarf and caked oil. I’ve got lots of clean-up ahead of me.

More later…………

Well, its been about a week or two since I’ve done anything of consequence on the old toad, and wanted to get some progress documented today. I took the spindle head apart the other night to check out the bearing noise, and found the taper side bearing race pretty pitted. I’ll get into that later, once I have all the parts in, but the overhaul on the spindle will probably be under $100. Most of the parts were easily accessible at the local auto parts store or Ebay. More on that later, when I can get it all together at once.

CAMS member Jeff Greenblatt tells me this old mill dates from 1947-1950. That helps, Thanks Jeff!

My first step this weekend was to throw some paint on the main column. The theory here is that if at least one part looks half way decent, more will follow. With the main body of the mill in paint, I can start hanging some parts.

One shot from the front, and one from the side. Pretty basic stuff, here. I stripped the paint with oven cleaner, and brushed on one coat (so far) of Rustoleum Smoke Grey (no primer). Might need another coat, this stuff tends to let any stray grease bleed through.

Next, I moved on the the knee (shown here up-side down). The Z axis screw was very tight when the mill was disassembled, but freed up when I soaked it in my mineral spirits tank. I thought it’d be a good idea to take it apart, and find out why it was tight. Turned out to be just dried grease.

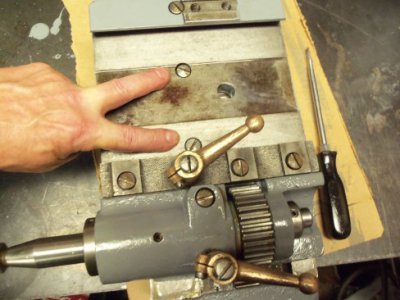

This is the 1st step, to take the Z screw out. The bevel gear is held on by a nut. The vice grips I am grabbing the shaft with are wore out, and have no teeth on them, so they don’t chew up anything I grab with them.

Heres the screw out, showing the roller bearing, and the beveled gear. I guess soaking it paid off; this all took about five minutes and it came apart real easy.

This is the shaft that was so tight, the Z axis. The beveled gear is pinned to the shaft with a tapered pin. One shot with a punch drove it out. The shaft pulled out from the front, once the gear was off the back of the shaft.

Here it is, with the dial back on.

Heres the Y axis screw. It came out pretty much the same as the other. There is a nut under the dial collar, that the screw rides in. Take this out with those wore out vice grips again.

This is everything on the knee. It took me about 30 minutes to get to this point. I had powerwashed everything before I started, and soaked everything with penetrating oil. That helped alot.

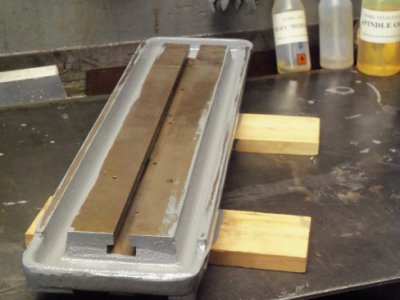

This is the top way on the knee; (Y axis) it is not worn at all, and the factory scraping looks fresh. Some Yutz rapped some marks in the top of the way, but I stoned the marks down, and doubt they’ll cause any friction. The rest of the ways cleaned up real nice.

This is the Z axis way; the vertical way that the knee slides on. Pretty much the same as the other ways, just caked on dried grease. A little while with a wire brush, some carb cleaner, and some Scotch Brite and some spindle oil, and they look brand new.The next step is to hit the main body of the knee with some more oven cleaner, and some paint, then throw it back together. More later…………

I spent the day stripping paint and painting, not alot to show “visually”, but made alot of progress. I got the knee re-cleaned and painted, the internal parts of the knee cleaned and ready for re-assembly, and the motor mount plate and a few other pieces stripped and painted. Heres a shot of the base, with the ways scrubbed and polished, and the upper gib installed. Nothing earthshaking.

Heres the motor mount and plate. I needed to get it apart to get the paint off. This stuff is real stubborn. Must have been on there from day one.

This is the first hurdle in the rebuild. The knee and its assorted pieces take up alot of space on my bench. After I got it apart and cleaned, it got two coats of paint. I hope to get it back together tomorrow, if the paints dry. It doesn’t look much different than the shots from yesterday, but alot of work went into cleaning these parts and the rest of the pile. I cleaned and painted alot of the peripheral pieces. Lots of work left to do, but thats all for today.

OK, the paints dry, and its time to go back to work. Its amazing how fast this thing goes back together when everything is clean.

The first step is to install the horizontal shaft for the Z axis.

The shaft comes in from the front, and the bevel gear is attached with a tapered pin.

Once the shaft is in, I installed the dial ring. Its held in by a screw.

This is the vertical screw for the Z axis. I slapped a little grease on it before I installed it.

The vertical and horizontal X gears installed.

Next is the Y screw. The collar screws in, and holds the screw from backing out. The hole in the collar lines up with the oil hole, so that you can lube the screw.

The X and Y screws and dials installed. I beveled the oil points, so that it would be easier to hit it with an oil dispenser. The holes were just cast holes before.

This is a shot of the back of the knee, with the gib installed, getting some way oil. The paint drips are on the section of the knee that doesn’t contact the base. The ways are clean.

This is what I have been working to see for a week or two. I wanted to see the knee back on and moving smoothly. When I bought the mill, the knee was VERY stiff. Aside from the bad bearing in the spindle head, this was the only issue I had with the mill. It turned out to be a very minor issue. The spindle bearing was something I discovered after, and I’m just as happy to have to deal with it, as I will have a solid tool when I’m done. Getting the knee on gives me instant gratification, and some fast inspiration.

Heres the next victim, the saddle. I have to hang this on the mill before the table goes on. There aren’t any issues with this piece, and I don’t expect any problems with it. Most of the heavy grunge is off of it, and it looks like a normal cleanup will be all it needs. Again, there is no wear that I can see.

10-22-11 I finally got a chance to work on the saddle today. I took it apart and cleaned it thoroughly, before throwing a coat of paint on it. I won’t be able to handle dry parts before tomorrow. The cleanup on the parts was a breeze, as everything was working properly, and in good shape. I didn’t take any pics of the breakdown, it was pretty self explanatory.

This is the total pile of parts off the saddle. You can see theres not much to it.

This is the top of the saddle after the cleaning.

And here is the bottom.

Heres the bottom, painted.

This is the top, painted, I will have to scrape some of the runs off the way surfaces, but I’ll get to that once its dry. I’ll go into a little more detail on the re-assembly, I got a little hot to get it apart, and didn’t take any pics. Its pretty straight forward, more tomorrow.

10-23-11; Parts dry, and ready to go back together. Lets get started.

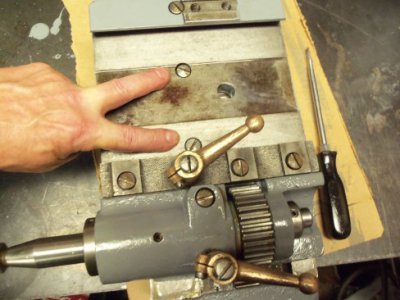

This is the sleeve that houses the X axis screw actuator (the lever that moves the table right and left). It has two holes; one that lines up to the oil port (for lube), and one that isn’t drilled all the way thru that locks the sleeve in place with an allen set screw. Make sure you get the holes in the right place.

Heres the sleeve installed, with the set screw in the hole on top, and the oil port down below.

All the clean parts, ready to go in. Notice the woodruff key in the shaft, that keys the gear to the shaft, and the stop collar to hold the shaft in place.

After a light coat of way lube, the parts slip right in. I’ve also installed the table gib. The screws and lock are just left snug enough to let the lock washers grab a little bit. Any tighter, and the table won’t go on.

******OK, HEED THESE WORDS!!!!!******

This would be a great time to fit the saddle to the cleaned table, and adjust the table gib. You may think the gib is loose enough, but now is the time to find out, instead of when you’re trying to do this ALONE, and find out the gib is set too tight. You CANNOT adjust the table gib once the saddle is installed. You can tighten the two outside screws to tighten the gib, but the inner screws are covered by the knee. Set the table gib tension on your workbench, before you install the saddle on the knee, and you will avoid having to take the saddle off again. Ask me how I know this!

*****THAT WILL SAVE YOU A LOT OF TIME******

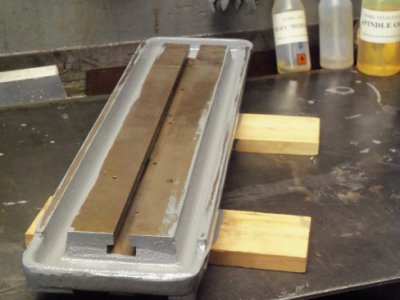

I decided to put a few pics out of sequence to drive the point home. This is the way to fit the table to the saddle prior to installing the saddle. It will save you from having to pull the saddle back off.

Here is the saddle and table (upside down on my bench, this is how you will be fitting the gibs.

Back off all four of the gib screws, and the gib locking lever to put the gib in the relaxed position.

With the other three screws backed off, these are the ONLY two screws that you will be adjusting the table tension with. They will be facing up, and you will not be able to get to them when the table is installed on the mill. Forget the other three screws for the time being, you’ll get to them later. Take your time , and take out all the slop in that gibs, it will pay off later.

Lube the saddle and the table with way oil. You want the saddle to slide smoothly, use plenty of lube.

Slide the saddle a few times and lube some more., adjusting the two center screws tighter as you go. At some point you will loose all the slop in the gibs, and will feel some resistance when you slide. Don’t go too tight, you can tighten the other three screws when you get the table on the mill to the point where the table will slide and lock nicely. This has been the only part of the job so far that has been what I’d call “picky”. Spend some time here, and you won’t regret it. I had to take my table off, and wish I had thought to do it right the first time.

Top view of the saddle.

Bottom of the saddle, with the Y axis gib installed (saddle to knee). Again, leave the screws just tight enough to grab the lock washer; you will adjust the gib tension later.

The saddle installed, with the table lever. The only thing left to do is install the two bolts on the right side that attach the Y axis screw to the saddle, and its ready to slide.

Front view; I’m making some progress, here. Notice the motor mount has been mounted, and I’m already hanging stuff on it.

Heres the bottom of the table (prior to cleaning). It shows the screw rack that contacts the gear in the saddle, and provides X travel.

I didn’t include any pics of the cleanup procedure, I’m sure you can figure that out. I was pumped to get the table in paint, so that I could get it hung, so I left the detail cleaning on the top side of the table until the paint dries, and it is on the base. I got all of the rust off, but want to stone the working surface CLEAN, cause thats what I’ll be looking at. I figure that might take a little time, and sitting on the mill will allow me to raise or lower it to the perfect height to work on. If I didn’t have lots more work to do, I’d be making some T nuts to mount the new vise I got at the CAMS yard sale, but that’ll have to wait. Next I have to mount the table, and start the spindle overhaul. OK, I discussed the difficulties I had mounting the table, and here it is:

I haven’t taken the time to do the final adjustment on the saddle or table gibs yet, but plan to do the knee, saddle, table and spindle head gibs all at the same time. On to the spindle head………

Heres the raw materials, clean (it doesn’t look like it), and ready for some parts.

Heres the parts: Two bearings, one race (the other one is perfect), and two seals. I’ll post the part numbers.

First step (after a detailed cleaning) is to select the right sized bushing driver, and drivethe race into the taper side of the spindle head.

With the race installed, the work on the head is about done. I still have a bunch of clean-up on the spindle, and other parts. At this point, I decided to get some paint on the hard to reach spots on the spindle head………..

And then I kinda got carried away. This’ll make final assembly a little trickier, but then I thought: why not just do the final assembly with the head hanging on the mill? I always like working at eye level better anyway, and at least the paint is pretty much done now. More later, when the paint is dry………

11/4/2011; A week or more has gone by, and I’ve been doing a little work on the spindle, but I’m still waiting to get the right taper side seal before I do the reassembly. I decided to turn the seal surface down and polish it, as it had been pretty badly eroded by 70+ years of swarf and rust. I just trimmed it by a thousandth or two, but I’m having a little problem getting the right fit on the spindle housing and spindle itself. More on that later, when I have all the parts together.

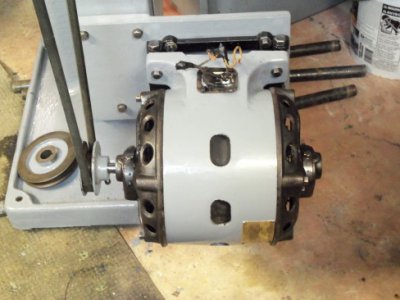

I decided to take the pulley assembly apart for cleaning. It was rolling around the shop, and it was bound to get damaged, so I dropped it on the bench and started taking it apart.

This looks fairly clean after three or four hits with oven cleaner and a pressure washer, but there is loads of grease and swarf in the nooks and crannies. The bearings are smooth, but packed with 70 year old grease.

It comes apart real easy, but has loads of dried, hardened grease on it.

The bearings are Fafnir units, a CV type, with ball bearings inside. I chose not to disassemble them, just soak, and power flush the old grease out. If you’ve ever taken apart a CV joint, you’ll know why I didn’t.

I soaked them in mineral spirits overnight to soften the grease, and the sprayed them for a long time with my air-solvent spray gun. They are plenty clean.

The shaft came out, without too much commotion. It all got polished before re-assembly.

All the parts got a quick coat of Rustoleum Smoke Gray.

The bearing housings with a little paint on them.

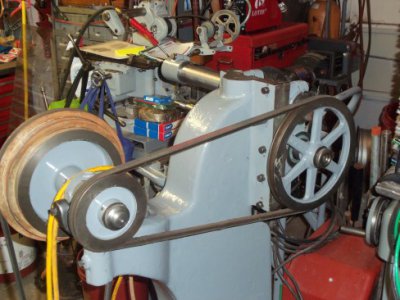

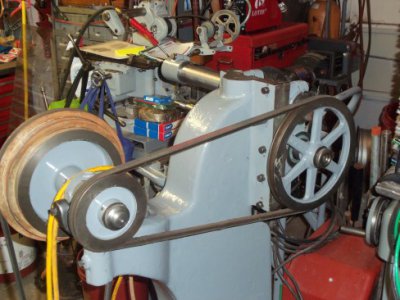

After the paint dried, I couldn’t resist a trial fitting. Its amazing how fast clean, polished parts go back together. I still have to do the final line-up and alignment, but they are ready for grease, and off my bench.

Heres another angle. Its starting to look like a mill, again. Time to get to cleaning up the motor mount and motor. Maybe this weekend.

11/7/2011: Still waiting on the “last” seal for the spindle, decided to dive into the motor and motor mount. The motor mount is “theoretically” adjustable, at least until somebody locked down the bottom castle nuts (which are supposed to be loose). Once I had all the parts clean, and the bottom nuts loose, it was real easy to do the adjustments.

Here it is, cleaned, assembled, and waiting for final adjustment.

The mount, mount-ed.

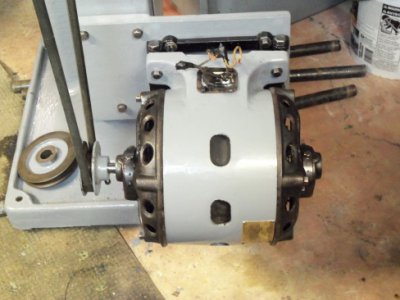

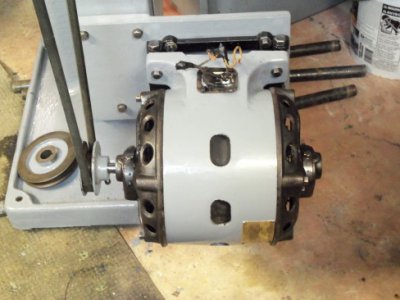

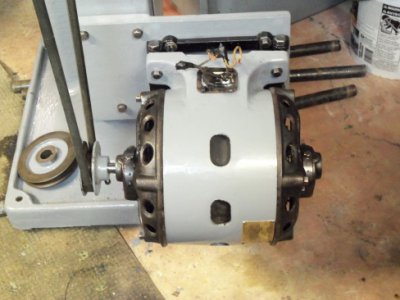

This will give you an idea how dirty the motor is. I had thought about just blowing the thing off, and installing it, but after a couple of triangular pieces of aluminum (which obviously didn’t belong to the motor) fell out, I figured I’d better get it apart.

This is the sight that greeted me, well worth cleaning up.

One of the benefits of tearing into something is having a good look at it. The fastest way to clean this would be to blast it with the pressure washer, but I worry about wearing the insulation off the windings. I always wash motors off in the parts washer, it gives me a chance to get a good look, and check for problems. None found, I dried it off and put on a coat of paint on the motor housing.

I had planned on painting the end bells black, but the last can I had went belly up, and I kinda liked the look of bare cast iron, so thats what they ended up as (clear coated, so they won’t rust).

The only casualty I found on the motor was a cracked (and previously repaired) pulley. It had been brazed, and turned on a lathe, and appeared to be a quality repair, so I decided to leave it alone. I don’t know if the final drive speed will be right, so I will make the decision as to weather or not to replace the pulley once I get it running. More later………

11/8/2011: I cleared a big hurdle today, I hung the motor on the mill. I had been avoiding this like the plague because of the weight. Theres no convenient way to pick this lump of iron up, without putting my motor hoist together, so I just set it on a 5 gallon pail, and kinda “shimmed” it in place. Kind of a Rube Goldberg arrangement, but more appealing than digging my cherry picker out from under a pile of stuff.

Heres the assembled motor on the bench. I only have two bolts on each bell because some of the bolts were mismatched (square head, screws, and original). I’ve gone this far, I might as well have eight matching bolts. The gits oilers will be in the vertical position when the motor is installed.

After wrestling this hulk for about a half hour, I was able to get it close to the correct position. I still have some fine tuning, but its on the mill.

Side view of the motor.

Another view from the side. It took a while to set the intermediate shaft so that the pulleys lined up right. I want to run this at the slowest speed, so I went to the largest pulley on the jack shaft. SIDE NOTE: I am used to seeing 1735 RPM on 220V motors, this one is 1165 RPM, making it even slower than what I was expecting.

This is a fuzzy shot of the front bell on the motor. Because the brush holder is not hard wired to the winding housing, I was able to rotate the bell from the original position with the oilers turned sideways, to this position, so that it will hold the oil in the sump.

I still have some work to do before I spin the motor and the jack shaft over, so I’ll take my time and make sure everything is kosher. I won’t have the spindle seal till later this week, so I’m in no hurry to get it running, but I will admit that I’m getting a little stoked, theres not many parts left in the parts basket. Now if I can just find a junction box that looks like it belongs on that motor, I’ll be all set………..

10/14/2011: The final parts came in for the spindle on Friday, and the motor is hung; I’ve run out of excuses for not having the spindle back together, so here it is:

I took a little time and re-cleaned the spindle area, and honed the over arm bore with a automotive cylinder hone. That was time well spent, the over arm slides much easier. I’ll probably polish the arm itself later to get it real smooth.

Here are the spindle parts in the orientation they will sit in when installed.

This is how they will sit in the spindle housing when assembled.

Here is the large bearing lubed, and installed in the race, ready for the seal to be installed. This is the taper side of the spindle (front as you face the machine).

The rear bearing and race installed.

The spindle slid in real nice and easy, because I took the time to pre-fit and polish everything. With both the bearings and seals in, the spindle just slides in from the front. The bearing spacer and pulley went in so fast I didn’t get any pics. The last step is to install the knurled locking ring (just like on the pulley jack-shaft). I rotated the spindle by hand quite a few times to check the bearing pre-load, and when I was pretty sure it was right, I started to get ready to spin it over, under power.

Admittedly, not one of my better pics, this is supposed to show that the spindle pulley and jack-shaft pulley in the rear are not perfectly aligned (off by about an eighth of an inch). I spent more time aligning the pulleys than I did assembling the spindle. Actually, it went pretty quickly, due to the spacer rings on the jack-shaft. Not a big deal at all. Took about five minutes to get the pulleys squared away.

You can’t tell from this shot, but the spindle is running (shutter speed to fast?). I got stoked to hear it run, and wired the motor up, and greased everything. The motor started instantly, and once the centrifigal weights flew out, it settled into an almost silent 1165 RPM hum. Very satisfying to hear the old gal run. I had filled the motor oilers with spindle oil, and greased the jack-shaft and spindle bearings with Mobil Extreme Pressure grease before letting it run. I was watching the spindle bearing temperature real close for temp rise, and it settled into an 84 degree temperature after about an hour of running. Pretty good in my eyes. I’ll probably go back, and recheck all the bearing pre-loads after its run a while, but I’m real happy with the way it sounds, so far. The motor winds up for about a half a second, the kicks the brushes off, and goes silent. About all you can hear is the belts slapping, and thats probably because the top belt is pretty well done. I plan on getting some more Fenner link belt for the top to see if I can get rid of the noise, and make some type of strain relief tensioner for the motor, to take the weight off the bottom belt. As it sits right now, the motor kinda “hangs” on the bottom belt. That will need attention.

The next step is to build some sort of mount for the motor starter I got at the CAMS Yard Sale last month, and address the belt tension issue, and then I might actually have to cut some metal with it…………..

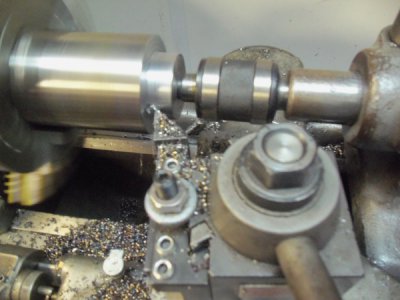

11/17/2011: Like most shake-down runs, some problems showed thier ugly heads;#1; I didn’t have the right tooling to do a proper test. #2: I was tired and impatient, and did something stupid; I fed the workpiece in from the wrong side (climb milling), something I was warned NOT to do. #3: I hadn’t really done anything more than a preliminary clean-up on the arbors (probably the most important part of the overhaul). The first step was to work on the arbors. The one inch arbor was the worst of the two, first step was to drag a VERY FINE draw file down the taper, to knock the high spots off. A purist will say that I’ve ruined the accuracy of this arbor. The fact is; a purist would have thrown this arbor out. I am NOT a purist. I knocked the high spots and burrs off, and chucked it up in the lathe to “make it round”, and polish it.

After I got it “round”, I polished it, and put some Dykem on it, and tried it in the spindle. Either the Dykem was too thick, or its not Prussian Blue, but it didn’t work out real well. Next time I’ll get some Prussian Blue, but I just blued the taper with a Magic Marker until I got a good pattern (it took a while. Heres the first try…….

After a couple of hours, I had two arbors that I was pretty sure were good to go. Turns out the 1″ arbor will need a little more work, but its almost there.

I chucked up a six toothed cutter ( 1/2″ wide) on the 1″ arbor, and tried to cut some steel, this is when I found out I had been “a little over-optimistic”. After about 5 minutes, I decided to call it a night, and call Dave to supply me with the right cutters to do some real work.

This is the pile of stuff the Old Chicken Thief dug up for me to get started. I’m sure I’ll need more, but I can do a few jobs I have in the hopper, and hes got loads more cutters that hes happy to part with.

I have resisted the urge to turn every piece of metal I own into scrap, until I take care of a few items. I still have a little work to do on the arbors, and I want a shut-off switch at arms reach. My first attempt to use some bad tooling (and my impatience) resulted in a slipping belt, and a stalled spindle. I WON’T make that mistake twice. I’m gonna take my time, and set the thing up right, and have some fun with it. I have a few more details to take care of before I feel comfortable running the thing up again. More later………

11/23/2011: I didn’t get alot of time to play with the mill this weekend; I started cleaning a spot in the corner of the shop for it, and one thing led to another. I went on a cleaning jag (long overdue), and got rid of a bunch of scrap.

I did swap the spindle and jack-shaft drive pulleys: this dropped my spindle speed from 700 RPM (it was being over-driven) to 200 RPM, a vast improvement in my view. I think (and have been told) that this will be a much better speed to run at.

Heres a shot from the back, after I swapped the pulleys. The one downside of this arrangement is that I will not be able to use the existing over-arm support with this pulley arrangement: it extends too far out the front to let the table arm go full travel. As luck would have it, I have a piece of 2 1/4″ shaft that will be perfect for a new over-arm support (straight out of the dumpster at work). I live a charmed life.

Heres where I figure will be the best spot for it, the corner between my lathe and mill (a kind of Black Hole). Pretty much dead space I use for stock storage, right now.

After a couple of hours of sliding my Bridgeport over, and moving all my small stock, I got the old mill in it’s “final resting place”. The off-shoot is that I have a GOOD spot for my band saw now, and the Bridgeport is in a better spot, too, and I actually ended up with enough room to (maybe) set up my surface grinder. I’ve had it for about three years, and never powered it up.

Of course, the rest of the shop is in disarray, but I think I can fix that with a few trips to the scrap metal dealer. I took one trip there today, and plan on a couple more in the next few weeks. I have no doubt that I’ll be hanging stuff on the new mill soon, but for now I’m trying to keep the area clear, so I can run a dedicated 220V circuit for the mill, the horizontal band saw, the welder and plasma cutter.

This move has opened a couple of spaces up to build some specific stands for some machines that get tossed on top of whatever has free space on them. Using up some of my angle iron should yield me some BIG benefits! More later………..

11/29/2011: More fiddling about, with the bulk of the “rebuild” done, I decided to clean up some odds and ends. I was testing the mill with it wired up to a plug, half way across the shop, with no switch. Not exactly the way I want to work, so I ran some conduit over to the mill, and wired up a recepticle there, and another on at the breaker panel. I plan on a couple more, but this will get the mill closer to being done. I still haven’t gotten around to the switch mount yet.

Heres the final wiring to the machine. I’ll wire the mill up later.

While I was at it, I wired up a dedicated 3 PH outlet from my nearest 3 PH drop. I wanted to be able to “plug into” my 3 PH power without having to break into the service. I got this idea when I bought my lathe; the guy had a long extension cord with jumpers on the end, and just drug the thing around to whatever machine he wanted to test. I test run alot of 3 PH motors, and having a portable power source will be a real help. I whipped up a 20 foot extension cord with three jumper ends on it, and wired it up with a plug that no other machine in the shop will use. This seemed to be a better idea than having a loose lead hanging out of the drop box in the corner.

This is a little neater than the old setup, and safer, too.

12/4/2011: I got a little time to work on the mill today, mounted the starter switch, made a new overarm support, and spent a little more time on the arbors.

This is the switch that I got at this years CAMS Yard Sale. I mounted it slightly angled back, and to the side, so that its right in the operators line of sight when running the machine, for quick access.

This is the “long” overarm support I got with the machine; too long to use with the short arbor (1″) that I plan on using alot (the table feed lever hits). I need to make a shorter overarm support.

This is a real nice chunk of 2 1/4″ stainless steel I had kicking around thats just a little too long (now).

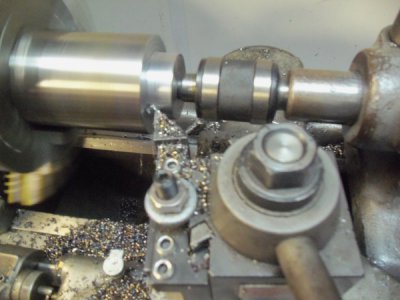

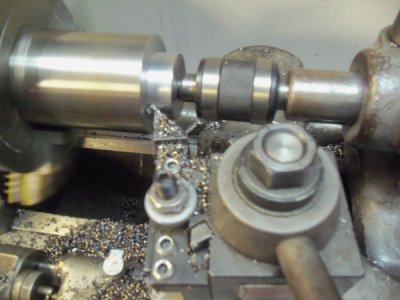

I had an old input shaft from a Ford A4LD transmission that was the right size to make a couple new arbor pilots for the new overarm support, and decided to make a couple of spares. This stuff is really hard, and it took me a while.

This is about a half hours work. Like I said; the stuffs hard.

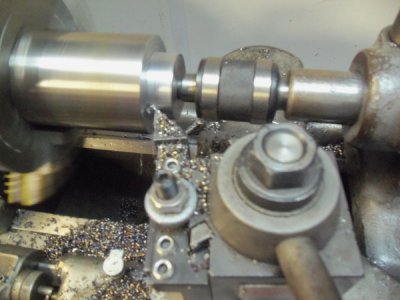

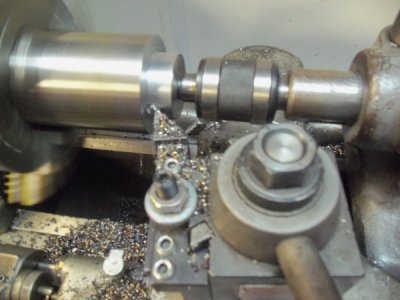

Heres the new overarm shaft getting trimmed in the old Johnson.

The new shaft and pilots mounted. Just enough clearance for the table lever to clear with the short arbor installed, and I still have the long overarm for the long arbor (7/8″). I think I’ll have to make up some kind of hand wheel to use with the long arbor, because the lever kind of limits the length of cut when it hits the arm.

I took a look at the face of the arbors where the new inserts will ride, and they looked, well “used”. I decided to face them off, so I will get a nice true register for the arbors. They weren’t as bad as they looked, and just took a light lick with a 60 degree counter sink.

This is the “tensioner” I made to take the bounce out of the motor. The motors weight sets on the lower pulley, and when the mill is running, the motor bounces a bit. Being that the motor is so heavy, I figure this can’t be good for the belt. Hopefully this will cut down on the belt vibration. I painted it, so its still drying.

I couldn’t resist a trial run on some aluminum. This cut was a 1/2″ deep, with a 1/2″ wide cutter, @ 200 RPM and it never slowed the machine down. I shot this with my left hand, while working the lever with my right. Theres a really nice “6″ about mid-screen. Once I check that the arbors are staying put in the spindle, I’ll try a good cut with some steel, but thats all for tonight. More later…………

Original at : http://bluechipmachineshop.com/bc_blog/rebuilding-a-burke-1-horizontal-milling-machine/

Rebuilding a United States Machine Tool Co. #1 Horizontal Milling Machine

Posted by mick on September 25, 2011

This entry is to document the disassembly, cleaning and overhaul of a Burke No. 1 Horizontal Mill purchased on 9/24/2011, its bound to be a lengthy process, bear with me.

The story starts with a friend (we’ll call him “Steve”), sending an Email to the CAMS group with a list of the goodies he’ll have for sale at the 2011 CAMS Yard Sale. One item that interested me was a Van Norman 1R mill, and I inquired about it. It turned out to be more mill than I needed, and I told him I was really looking for a dedicated horizontal mill, without all the bells and whistles; a “crab”. At this point he mentions the old Burke might be what I’m looking for. Fully operational, ugly, and cheap, I’m hooked. Steve is a crafty individual; He knows if its ugly and cheap, I’ll probably be interested. He asked me (after the money changed hands) “Did you feel it when I set the hook?”. Frankly, I never saw it coming. All kidding aside; Thanks for the great deal, Steve. This is the sight that greeted me when I arrived at the Stallings Institute of Industrial Antiquities:

The pics don’t really show just how dirty and ugly this thing is, you have to see it up close. Its saving grace is that it is fully functional and complete, except for a couple of hand wheels. It moves smoothly, and it appears that everything works. You can get filthy just standing next to it.

This is a shot of the movable head (counterbalanced by a weight inside the base). It is a Browne & Sharp #9 taper, and an arbor is included in the sale.

This is the table rack. This will give you an idea of the clean up in store for me. The mill is a “hand mill”, meaning there is no power feed; the table is advanced with a lever on a rack and pinion arrangement.

Heres a shot of the back (shooting into the light), showing the pulley arrangement; a very stout affair.

And a shot of the pulleys. A very solid setup.

Here’s the motor, a 220V Century. You can see the motor mount on this mill is pretty substantial. The motor and mount probably weigh 100 Lbs.

I haven’t taken delivery of the mill yet (scheduled for Oct 1), but I’m anxious to get started on the overhaul. I don’t plan on making it a museum piece, but want something that doesn’t make you cringe to look at it. Right now it looks like it fell out of the Ugly Tree, and hit every branch on the way down. More importantly, I want everything on the mill to function smoothly, and accurately. The best way I know to do this is to get the thing apart and see whats broken/worn/rusty.

I have high hopes for this, based on its overall condition (look beyond the paint and grease), its a nice heavy machine, and should be fun to work on.

***UPDATE***

Well, it didn’t take long for somebody to correct me; Irby on the Yahoo Burke site informed me that this is actually a United States Machine Tool Company mill, built prior to the merger of USMT Co. and Burke in the mid 60′s. Thanks Irby.

More later……….

ONE WEEK LATER:

Heres the main column sitting in the driveway, ready for a clean-up (REALLY ready).

This is after the first of four treatments of Easy-Off oven cleaner. Spray it on, and let it sit for 10-15 minutes. The years of caked on dried oil and swarf just fly off when you hit it with a pressure washer.

Heres a shot of the back side, after 3 treatments of oven cleaner. The old paint just kinda dissolves (there was about 4 coats). The prime coat is somewhat more stubborn, and will probably remain on for posterity.

This is the front side, and is pretty much down to bare metal, and ready for paint. Once that is done, I can start hanging parts, (yet to be stripped). Once I get the base placed in the shop, I plan on rebuilding the larger parts first. This means working my way from bottom to top, with the last part to be done: the spindle head. This will allow me a little time to locate bearings and seals, as this is the only area of the mill that is even a bit “iffy”. Nothing really drastic, but with the head laying on my steel bench, a slight “rumble” showed its self. I haven’t had time to investigate, and I suspect it might just be the noise being amplified by the bench. We’ll see.

Heres some of the swarf and dried oil thats plastered all over this machine. It doesn’t come off easily, oven cleaner is the easiest way I’ve found.

It took me an hour or two to find the serial number (9365 R). Its on the front edge of the knee.

This is the only tag I found identifying it as ” Mfd by U.S. Machine Tool Co. Cincinnati, Ohio”. This was on the bottom of the spindle head. Lots more swarf and caked oil. I’ve got lots of clean-up ahead of me.

More later…………

Well, its been about a week or two since I’ve done anything of consequence on the old toad, and wanted to get some progress documented today. I took the spindle head apart the other night to check out the bearing noise, and found the taper side bearing race pretty pitted. I’ll get into that later, once I have all the parts in, but the overhaul on the spindle will probably be under $100. Most of the parts were easily accessible at the local auto parts store or Ebay. More on that later, when I can get it all together at once.

CAMS member Jeff Greenblatt tells me this old mill dates from 1947-1950. That helps, Thanks Jeff!

My first step this weekend was to throw some paint on the main column. The theory here is that if at least one part looks half way decent, more will follow. With the main body of the mill in paint, I can start hanging some parts.

One shot from the front, and one from the side. Pretty basic stuff, here. I stripped the paint with oven cleaner, and brushed on one coat (so far) of Rustoleum Smoke Grey (no primer). Might need another coat, this stuff tends to let any stray grease bleed through.

Next, I moved on the the knee (shown here up-side down). The Z axis screw was very tight when the mill was disassembled, but freed up when I soaked it in my mineral spirits tank. I thought it’d be a good idea to take it apart, and find out why it was tight. Turned out to be just dried grease.

This is the 1st step, to take the Z screw out. The bevel gear is held on by a nut. The vice grips I am grabbing the shaft with are wore out, and have no teeth on them, so they don’t chew up anything I grab with them.

Heres the screw out, showing the roller bearing, and the beveled gear. I guess soaking it paid off; this all took about five minutes and it came apart real easy.

This is the shaft that was so tight, the Z axis. The beveled gear is pinned to the shaft with a tapered pin. One shot with a punch drove it out. The shaft pulled out from the front, once the gear was off the back of the shaft.

Here it is, with the dial back on.

Heres the Y axis screw. It came out pretty much the same as the other. There is a nut under the dial collar, that the screw rides in. Take this out with those wore out vice grips again.

This is everything on the knee. It took me about 30 minutes to get to this point. I had powerwashed everything before I started, and soaked everything with penetrating oil. That helped alot.

This is the top way on the knee; (Y axis) it is not worn at all, and the factory scraping looks fresh. Some Yutz rapped some marks in the top of the way, but I stoned the marks down, and doubt they’ll cause any friction. The rest of the ways cleaned up real nice.

This is the Z axis way; the vertical way that the knee slides on. Pretty much the same as the other ways, just caked on dried grease. A little while with a wire brush, some carb cleaner, and some Scotch Brite and some spindle oil, and they look brand new.The next step is to hit the main body of the knee with some more oven cleaner, and some paint, then throw it back together. More later…………

I spent the day stripping paint and painting, not alot to show “visually”, but made alot of progress. I got the knee re-cleaned and painted, the internal parts of the knee cleaned and ready for re-assembly, and the motor mount plate and a few other pieces stripped and painted. Heres a shot of the base, with the ways scrubbed and polished, and the upper gib installed. Nothing earthshaking.

Heres the motor mount and plate. I needed to get it apart to get the paint off. This stuff is real stubborn. Must have been on there from day one.

This is the first hurdle in the rebuild. The knee and its assorted pieces take up alot of space on my bench. After I got it apart and cleaned, it got two coats of paint. I hope to get it back together tomorrow, if the paints dry. It doesn’t look much different than the shots from yesterday, but alot of work went into cleaning these parts and the rest of the pile. I cleaned and painted alot of the peripheral pieces. Lots of work left to do, but thats all for today.

OK, the paints dry, and its time to go back to work. Its amazing how fast this thing goes back together when everything is clean.

The first step is to install the horizontal shaft for the Z axis.

The shaft comes in from the front, and the bevel gear is attached with a tapered pin.

Once the shaft is in, I installed the dial ring. Its held in by a screw.

This is the vertical screw for the Z axis. I slapped a little grease on it before I installed it.

The vertical and horizontal X gears installed.

Next is the Y screw. The collar screws in, and holds the screw from backing out. The hole in the collar lines up with the oil hole, so that you can lube the screw.

The X and Y screws and dials installed. I beveled the oil points, so that it would be easier to hit it with an oil dispenser. The holes were just cast holes before.

This is a shot of the back of the knee, with the gib installed, getting some way oil. The paint drips are on the section of the knee that doesn’t contact the base. The ways are clean.

This is what I have been working to see for a week or two. I wanted to see the knee back on and moving smoothly. When I bought the mill, the knee was VERY stiff. Aside from the bad bearing in the spindle head, this was the only issue I had with the mill. It turned out to be a very minor issue. The spindle bearing was something I discovered after, and I’m just as happy to have to deal with it, as I will have a solid tool when I’m done. Getting the knee on gives me instant gratification, and some fast inspiration.

Heres the next victim, the saddle. I have to hang this on the mill before the table goes on. There aren’t any issues with this piece, and I don’t expect any problems with it. Most of the heavy grunge is off of it, and it looks like a normal cleanup will be all it needs. Again, there is no wear that I can see.

10-22-11 I finally got a chance to work on the saddle today. I took it apart and cleaned it thoroughly, before throwing a coat of paint on it. I won’t be able to handle dry parts before tomorrow. The cleanup on the parts was a breeze, as everything was working properly, and in good shape. I didn’t take any pics of the breakdown, it was pretty self explanatory.

This is the total pile of parts off the saddle. You can see theres not much to it.

This is the top of the saddle after the cleaning.

And here is the bottom.

Heres the bottom, painted.

This is the top, painted, I will have to scrape some of the runs off the way surfaces, but I’ll get to that once its dry. I’ll go into a little more detail on the re-assembly, I got a little hot to get it apart, and didn’t take any pics. Its pretty straight forward, more tomorrow.

10-23-11; Parts dry, and ready to go back together. Lets get started.

This is the sleeve that houses the X axis screw actuator (the lever that moves the table right and left). It has two holes; one that lines up to the oil port (for lube), and one that isn’t drilled all the way thru that locks the sleeve in place with an allen set screw. Make sure you get the holes in the right place.

Heres the sleeve installed, with the set screw in the hole on top, and the oil port down below.

All the clean parts, ready to go in. Notice the woodruff key in the shaft, that keys the gear to the shaft, and the stop collar to hold the shaft in place.

After a light coat of way lube, the parts slip right in. I’ve also installed the table gib. The screws and lock are just left snug enough to let the lock washers grab a little bit. Any tighter, and the table won’t go on.

******OK, HEED THESE WORDS!!!!!******

This would be a great time to fit the saddle to the cleaned table, and adjust the table gib. You may think the gib is loose enough, but now is the time to find out, instead of when you’re trying to do this ALONE, and find out the gib is set too tight. You CANNOT adjust the table gib once the saddle is installed. You can tighten the two outside screws to tighten the gib, but the inner screws are covered by the knee. Set the table gib tension on your workbench, before you install the saddle on the knee, and you will avoid having to take the saddle off again. Ask me how I know this!

*****THAT WILL SAVE YOU A LOT OF TIME******

I decided to put a few pics out of sequence to drive the point home. This is the way to fit the table to the saddle prior to installing the saddle. It will save you from having to pull the saddle back off.

Here is the saddle and table (upside down on my bench, this is how you will be fitting the gibs.

Back off all four of the gib screws, and the gib locking lever to put the gib in the relaxed position.

With the other three screws backed off, these are the ONLY two screws that you will be adjusting the table tension with. They will be facing up, and you will not be able to get to them when the table is installed on the mill. Forget the other three screws for the time being, you’ll get to them later. Take your time , and take out all the slop in that gibs, it will pay off later.

Lube the saddle and the table with way oil. You want the saddle to slide smoothly, use plenty of lube.

Slide the saddle a few times and lube some more., adjusting the two center screws tighter as you go. At some point you will loose all the slop in the gibs, and will feel some resistance when you slide. Don’t go too tight, you can tighten the other three screws when you get the table on the mill to the point where the table will slide and lock nicely. This has been the only part of the job so far that has been what I’d call “picky”. Spend some time here, and you won’t regret it. I had to take my table off, and wish I had thought to do it right the first time.

Top view of the saddle.

Bottom of the saddle, with the Y axis gib installed (saddle to knee). Again, leave the screws just tight enough to grab the lock washer; you will adjust the gib tension later.

The saddle installed, with the table lever. The only thing left to do is install the two bolts on the right side that attach the Y axis screw to the saddle, and its ready to slide.

Front view; I’m making some progress, here. Notice the motor mount has been mounted, and I’m already hanging stuff on it.

Heres the bottom of the table (prior to cleaning). It shows the screw rack that contacts the gear in the saddle, and provides X travel.

I didn’t include any pics of the cleanup procedure, I’m sure you can figure that out. I was pumped to get the table in paint, so that I could get it hung, so I left the detail cleaning on the top side of the table until the paint dries, and it is on the base. I got all of the rust off, but want to stone the working surface CLEAN, cause thats what I’ll be looking at. I figure that might take a little time, and sitting on the mill will allow me to raise or lower it to the perfect height to work on. If I didn’t have lots more work to do, I’d be making some T nuts to mount the new vise I got at the CAMS yard sale, but that’ll have to wait. Next I have to mount the table, and start the spindle overhaul. OK, I discussed the difficulties I had mounting the table, and here it is:

I haven’t taken the time to do the final adjustment on the saddle or table gibs yet, but plan to do the knee, saddle, table and spindle head gibs all at the same time. On to the spindle head………

Heres the raw materials, clean (it doesn’t look like it), and ready for some parts.

Heres the parts: Two bearings, one race (the other one is perfect), and two seals. I’ll post the part numbers.

First step (after a detailed cleaning) is to select the right sized bushing driver, and drivethe race into the taper side of the spindle head.

With the race installed, the work on the head is about done. I still have a bunch of clean-up on the spindle, and other parts. At this point, I decided to get some paint on the hard to reach spots on the spindle head………..

And then I kinda got carried away. This’ll make final assembly a little trickier, but then I thought: why not just do the final assembly with the head hanging on the mill? I always like working at eye level better anyway, and at least the paint is pretty much done now. More later, when the paint is dry………

11/4/2011; A week or more has gone by, and I’ve been doing a little work on the spindle, but I’m still waiting to get the right taper side seal before I do the reassembly. I decided to turn the seal surface down and polish it, as it had been pretty badly eroded by 70+ years of swarf and rust. I just trimmed it by a thousandth or two, but I’m having a little problem getting the right fit on the spindle housing and spindle itself. More on that later, when I have all the parts together.

I decided to take the pulley assembly apart for cleaning. It was rolling around the shop, and it was bound to get damaged, so I dropped it on the bench and started taking it apart.

This looks fairly clean after three or four hits with oven cleaner and a pressure washer, but there is loads of grease and swarf in the nooks and crannies. The bearings are smooth, but packed with 70 year old grease.

It comes apart real easy, but has loads of dried, hardened grease on it.

The bearings are Fafnir units, a CV type, with ball bearings inside. I chose not to disassemble them, just soak, and power flush the old grease out. If you’ve ever taken apart a CV joint, you’ll know why I didn’t.

I soaked them in mineral spirits overnight to soften the grease, and the sprayed them for a long time with my air-solvent spray gun. They are plenty clean.

The shaft came out, without too much commotion. It all got polished before re-assembly.

All the parts got a quick coat of Rustoleum Smoke Gray.

The bearing housings with a little paint on them.

After the paint dried, I couldn’t resist a trial fitting. Its amazing how fast clean, polished parts go back together. I still have to do the final line-up and alignment, but they are ready for grease, and off my bench.

Heres another angle. Its starting to look like a mill, again. Time to get to cleaning up the motor mount and motor. Maybe this weekend.

11/7/2011: Still waiting on the “last” seal for the spindle, decided to dive into the motor and motor mount. The motor mount is “theoretically” adjustable, at least until somebody locked down the bottom castle nuts (which are supposed to be loose). Once I had all the parts clean, and the bottom nuts loose, it was real easy to do the adjustments.

Here it is, cleaned, assembled, and waiting for final adjustment.

The mount, mount-ed.

This will give you an idea how dirty the motor is. I had thought about just blowing the thing off, and installing it, but after a couple of triangular pieces of aluminum (which obviously didn’t belong to the motor) fell out, I figured I’d better get it apart.

This is the sight that greeted me, well worth cleaning up.

One of the benefits of tearing into something is having a good look at it. The fastest way to clean this would be to blast it with the pressure washer, but I worry about wearing the insulation off the windings. I always wash motors off in the parts washer, it gives me a chance to get a good look, and check for problems. None found, I dried it off and put on a coat of paint on the motor housing.

I had planned on painting the end bells black, but the last can I had went belly up, and I kinda liked the look of bare cast iron, so thats what they ended up as (clear coated, so they won’t rust).

The only casualty I found on the motor was a cracked (and previously repaired) pulley. It had been brazed, and turned on a lathe, and appeared to be a quality repair, so I decided to leave it alone. I don’t know if the final drive speed will be right, so I will make the decision as to weather or not to replace the pulley once I get it running. More later………

11/8/2011: I cleared a big hurdle today, I hung the motor on the mill. I had been avoiding this like the plague because of the weight. Theres no convenient way to pick this lump of iron up, without putting my motor hoist together, so I just set it on a 5 gallon pail, and kinda “shimmed” it in place. Kind of a Rube Goldberg arrangement, but more appealing than digging my cherry picker out from under a pile of stuff.

Heres the assembled motor on the bench. I only have two bolts on each bell because some of the bolts were mismatched (square head, screws, and original). I’ve gone this far, I might as well have eight matching bolts. The gits oilers will be in the vertical position when the motor is installed.

After wrestling this hulk for about a half hour, I was able to get it close to the correct position. I still have some fine tuning, but its on the mill.

Side view of the motor.

Another view from the side. It took a while to set the intermediate shaft so that the pulleys lined up right. I want to run this at the slowest speed, so I went to the largest pulley on the jack shaft. SIDE NOTE: I am used to seeing 1735 RPM on 220V motors, this one is 1165 RPM, making it even slower than what I was expecting.

This is a fuzzy shot of the front bell on the motor. Because the brush holder is not hard wired to the winding housing, I was able to rotate the bell from the original position with the oilers turned sideways, to this position, so that it will hold the oil in the sump.

I still have some work to do before I spin the motor and the jack shaft over, so I’ll take my time and make sure everything is kosher. I won’t have the spindle seal till later this week, so I’m in no hurry to get it running, but I will admit that I’m getting a little stoked, theres not many parts left in the parts basket. Now if I can just find a junction box that looks like it belongs on that motor, I’ll be all set………..

10/14/2011: The final parts came in for the spindle on Friday, and the motor is hung; I’ve run out of excuses for not having the spindle back together, so here it is:

I took a little time and re-cleaned the spindle area, and honed the over arm bore with a automotive cylinder hone. That was time well spent, the over arm slides much easier. I’ll probably polish the arm itself later to get it real smooth.

Here are the spindle parts in the orientation they will sit in when installed.

This is how they will sit in the spindle housing when assembled.

Here is the large bearing lubed, and installed in the race, ready for the seal to be installed. This is the taper side of the spindle (front as you face the machine).

The rear bearing and race installed.

The spindle slid in real nice and easy, because I took the time to pre-fit and polish everything. With both the bearings and seals in, the spindle just slides in from the front. The bearing spacer and pulley went in so fast I didn’t get any pics. The last step is to install the knurled locking ring (just like on the pulley jack-shaft). I rotated the spindle by hand quite a few times to check the bearing pre-load, and when I was pretty sure it was right, I started to get ready to spin it over, under power.

Admittedly, not one of my better pics, this is supposed to show that the spindle pulley and jack-shaft pulley in the rear are not perfectly aligned (off by about an eighth of an inch). I spent more time aligning the pulleys than I did assembling the spindle. Actually, it went pretty quickly, due to the spacer rings on the jack-shaft. Not a big deal at all. Took about five minutes to get the pulleys squared away.

You can’t tell from this shot, but the spindle is running (shutter speed to fast?). I got stoked to hear it run, and wired the motor up, and greased everything. The motor started instantly, and once the centrifigal weights flew out, it settled into an almost silent 1165 RPM hum. Very satisfying to hear the old gal run. I had filled the motor oilers with spindle oil, and greased the jack-shaft and spindle bearings with Mobil Extreme Pressure grease before letting it run. I was watching the spindle bearing temperature real close for temp rise, and it settled into an 84 degree temperature after about an hour of running. Pretty good in my eyes. I’ll probably go back, and recheck all the bearing pre-loads after its run a while, but I’m real happy with the way it sounds, so far. The motor winds up for about a half a second, the kicks the brushes off, and goes silent. About all you can hear is the belts slapping, and thats probably because the top belt is pretty well done. I plan on getting some more Fenner link belt for the top to see if I can get rid of the noise, and make some type of strain relief tensioner for the motor, to take the weight off the bottom belt. As it sits right now, the motor kinda “hangs” on the bottom belt. That will need attention.

The next step is to build some sort of mount for the motor starter I got at the CAMS Yard Sale last month, and address the belt tension issue, and then I might actually have to cut some metal with it…………..

11/17/2011: Like most shake-down runs, some problems showed thier ugly heads;#1; I didn’t have the right tooling to do a proper test. #2: I was tired and impatient, and did something stupid; I fed the workpiece in from the wrong side (climb milling), something I was warned NOT to do. #3: I hadn’t really done anything more than a preliminary clean-up on the arbors (probably the most important part of the overhaul). The first step was to work on the arbors. The one inch arbor was the worst of the two, first step was to drag a VERY FINE draw file down the taper, to knock the high spots off. A purist will say that I’ve ruined the accuracy of this arbor. The fact is; a purist would have thrown this arbor out. I am NOT a purist. I knocked the high spots and burrs off, and chucked it up in the lathe to “make it round”, and polish it.

After I got it “round”, I polished it, and put some Dykem on it, and tried it in the spindle. Either the Dykem was too thick, or its not Prussian Blue, but it didn’t work out real well. Next time I’ll get some Prussian Blue, but I just blued the taper with a Magic Marker until I got a good pattern (it took a while. Heres the first try…….

After a couple of hours, I had two arbors that I was pretty sure were good to go. Turns out the 1″ arbor will need a little more work, but its almost there.

I chucked up a six toothed cutter ( 1/2″ wide) on the 1″ arbor, and tried to cut some steel, this is when I found out I had been “a little over-optimistic”. After about 5 minutes, I decided to call it a night, and call Dave to supply me with the right cutters to do some real work.

This is the pile of stuff the Old Chicken Thief dug up for me to get started. I’m sure I’ll need more, but I can do a few jobs I have in the hopper, and hes got loads more cutters that hes happy to part with.

I have resisted the urge to turn every piece of metal I own into scrap, until I take care of a few items. I still have a little work to do on the arbors, and I want a shut-off switch at arms reach. My first attempt to use some bad tooling (and my impatience) resulted in a slipping belt, and a stalled spindle. I WON’T make that mistake twice. I’m gonna take my time, and set the thing up right, and have some fun with it. I have a few more details to take care of before I feel comfortable running the thing up again. More later………

11/23/2011: I didn’t get alot of time to play with the mill this weekend; I started cleaning a spot in the corner of the shop for it, and one thing led to another. I went on a cleaning jag (long overdue), and got rid of a bunch of scrap.

I did swap the spindle and jack-shaft drive pulleys: this dropped my spindle speed from 700 RPM (it was being over-driven) to 200 RPM, a vast improvement in my view. I think (and have been told) that this will be a much better speed to run at.

Heres a shot from the back, after I swapped the pulleys. The one downside of this arrangement is that I will not be able to use the existing over-arm support with this pulley arrangement: it extends too far out the front to let the table arm go full travel. As luck would have it, I have a piece of 2 1/4″ shaft that will be perfect for a new over-arm support (straight out of the dumpster at work). I live a charmed life.

Heres where I figure will be the best spot for it, the corner between my lathe and mill (a kind of Black Hole). Pretty much dead space I use for stock storage, right now.

After a couple of hours of sliding my Bridgeport over, and moving all my small stock, I got the old mill in it’s “final resting place”. The off-shoot is that I have a GOOD spot for my band saw now, and the Bridgeport is in a better spot, too, and I actually ended up with enough room to (maybe) set up my surface grinder. I’ve had it for about three years, and never powered it up.

Of course, the rest of the shop is in disarray, but I think I can fix that with a few trips to the scrap metal dealer. I took one trip there today, and plan on a couple more in the next few weeks. I have no doubt that I’ll be hanging stuff on the new mill soon, but for now I’m trying to keep the area clear, so I can run a dedicated 220V circuit for the mill, the horizontal band saw, the welder and plasma cutter.

This move has opened a couple of spaces up to build some specific stands for some machines that get tossed on top of whatever has free space on them. Using up some of my angle iron should yield me some BIG benefits! More later………..

11/29/2011: More fiddling about, with the bulk of the “rebuild” done, I decided to clean up some odds and ends. I was testing the mill with it wired up to a plug, half way across the shop, with no switch. Not exactly the way I want to work, so I ran some conduit over to the mill, and wired up a recepticle there, and another on at the breaker panel. I plan on a couple more, but this will get the mill closer to being done. I still haven’t gotten around to the switch mount yet.

Heres the final wiring to the machine. I’ll wire the mill up later.

While I was at it, I wired up a dedicated 3 PH outlet from my nearest 3 PH drop. I wanted to be able to “plug into” my 3 PH power without having to break into the service. I got this idea when I bought my lathe; the guy had a long extension cord with jumpers on the end, and just drug the thing around to whatever machine he wanted to test. I test run alot of 3 PH motors, and having a portable power source will be a real help. I whipped up a 20 foot extension cord with three jumper ends on it, and wired it up with a plug that no other machine in the shop will use. This seemed to be a better idea than having a loose lead hanging out of the drop box in the corner.

This is a little neater than the old setup, and safer, too.

12/4/2011: I got a little time to work on the mill today, mounted the starter switch, made a new overarm support, and spent a little more time on the arbors.

This is the switch that I got at this years CAMS Yard Sale. I mounted it slightly angled back, and to the side, so that its right in the operators line of sight when running the machine, for quick access.

This is the “long” overarm support I got with the machine; too long to use with the short arbor (1″) that I plan on using alot (the table feed lever hits). I need to make a shorter overarm support.

This is a real nice chunk of 2 1/4″ stainless steel I had kicking around thats just a little too long (now).

I had an old input shaft from a Ford A4LD transmission that was the right size to make a couple new arbor pilots for the new overarm support, and decided to make a couple of spares. This stuff is really hard, and it took me a while.

This is about a half hours work. Like I said; the stuffs hard.

Heres the new overarm shaft getting trimmed in the old Johnson.

The new shaft and pilots mounted. Just enough clearance for the table lever to clear with the short arbor installed, and I still have the long overarm for the long arbor (7/8″). I think I’ll have to make up some kind of hand wheel to use with the long arbor, because the lever kind of limits the length of cut when it hits the arm.

I took a look at the face of the arbors where the new inserts will ride, and they looked, well “used”. I decided to face them off, so I will get a nice true register for the arbors. They weren’t as bad as they looked, and just took a light lick with a 60 degree counter sink.

This is the “tensioner” I made to take the bounce out of the motor. The motors weight sets on the lower pulley, and when the mill is running, the motor bounces a bit. Being that the motor is so heavy, I figure this can’t be good for the belt. Hopefully this will cut down on the belt vibration. I painted it, so its still drying.

I couldn’t resist a trial run on some aluminum. This cut was a 1/2″ deep, with a 1/2″ wide cutter, @ 200 RPM and it never slowed the machine down. I shot this with my left hand, while working the lever with my right. Theres a really nice “6″ about mid-screen. Once I check that the arbors are staying put in the spindle, I’ll try a good cut with some steel, but thats all for tonight. More later…………

Last edited by a moderator: