- Joined

- Oct 30, 2019

- Messages

- 225

At an auction this past week I picked up a bunch of stuff from a local machine shop auction once I knew I was making the drive up. One lot was a "6-jaw chuck" with no other details available. This came home with me for about $35-40 after all fees

This ended up being probably the best value/item I got at this auction, the 6-jaw chuck turned out to be a Buck 4862 8.5" -- a pretty good fit for my Colchester Chipmaster once I get a backplate for it.

Unloaded everything from the truck on a few pallets

The chuck plus the backplate it was on probably weighed at least 80-100 lbs, the backplate is a monster

4862

Cracked this open and was met with a few things

- The HORRIBLE stench of anaerobic rancid oil/grease

- A surprisingly high amount of small chips made it inside the chuck

I threw the jaws in the ultrasonic cleaner and they cleaned up quite nicely. After the picture below I ended up using a scotch brite wheel on a die grinder to polish some of the staining off. No signs of damage/wear on the jaws

Cleaned up the rest of the parts in the parts washer, then ultrasonic, then back to the parts washer to knock any remaining softened stuff off. Blew off with blow nozzle, wiped the outside surfaces of the parts down with paste wax to prevent flash rusting

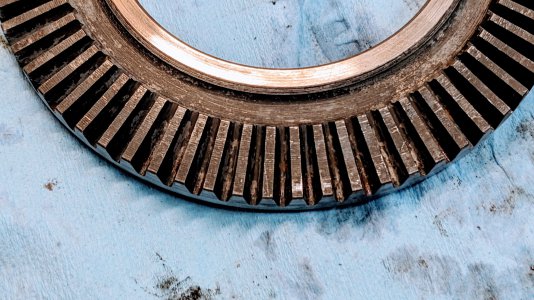

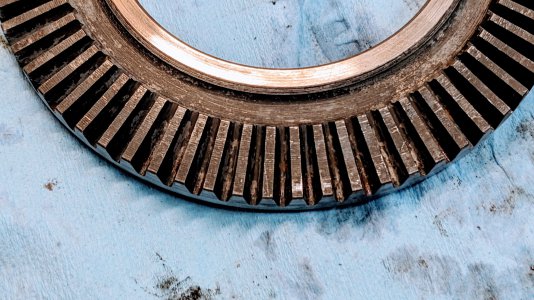

The scroll and gear teeth all look really good

And the main housing cleaned up nice

I opted to not deliberate the "oil versus grease" situation too much. I used Yamalube moly grease on the gear and scroll. On the running ways of the jaws I used way oil.

Reassembled and feels quite good. Looking forward to getting this mounted and trued up, and seeing if it provides the repeatability I hope it can bring to the shop

Overall spent maybe 2 hours on this, it went pretty quickly. The most difficult part was the pinion being a bit stubborn to come out until cleaning some grease/chips out of its cavity; and the 4 fasteners for the register adjustment had a bit of impacts around the top of them that made them difficult to remove. I ended up just forcing them out instead of taking a die grinder to cut back the outermost damage thread, which ended up being a reasonable decision.

Thanks for reading

This ended up being probably the best value/item I got at this auction, the 6-jaw chuck turned out to be a Buck 4862 8.5" -- a pretty good fit for my Colchester Chipmaster once I get a backplate for it.

Unloaded everything from the truck on a few pallets

The chuck plus the backplate it was on probably weighed at least 80-100 lbs, the backplate is a monster

4862

Cracked this open and was met with a few things

- The HORRIBLE stench of anaerobic rancid oil/grease

- A surprisingly high amount of small chips made it inside the chuck

I threw the jaws in the ultrasonic cleaner and they cleaned up quite nicely. After the picture below I ended up using a scotch brite wheel on a die grinder to polish some of the staining off. No signs of damage/wear on the jaws

Cleaned up the rest of the parts in the parts washer, then ultrasonic, then back to the parts washer to knock any remaining softened stuff off. Blew off with blow nozzle, wiped the outside surfaces of the parts down with paste wax to prevent flash rusting

The scroll and gear teeth all look really good

And the main housing cleaned up nice

I opted to not deliberate the "oil versus grease" situation too much. I used Yamalube moly grease on the gear and scroll. On the running ways of the jaws I used way oil.

Reassembled and feels quite good. Looking forward to getting this mounted and trued up, and seeing if it provides the repeatability I hope it can bring to the shop

Overall spent maybe 2 hours on this, it went pretty quickly. The most difficult part was the pinion being a bit stubborn to come out until cleaning some grease/chips out of its cavity; and the 4 fasteners for the register adjustment had a bit of impacts around the top of them that made them difficult to remove. I ended up just forcing them out instead of taking a die grinder to cut back the outermost damage thread, which ended up being a reasonable decision.

Thanks for reading

What shop was it ?

What shop was it ?