- Joined

- Apr 28, 2014

- Messages

- 3,592

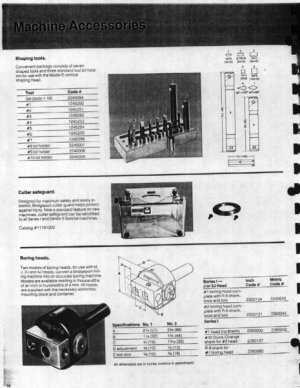

I've got this set of what I believe are Shaper Cutters. Am I in the ballpark?

A few have markings:

st-5 1-24-5254

bridgeport

-=-

st-3 1-24-5252

bridgeport

7/79

-=-

The long one is stamped Cincinnati Milling Machine Co.

-=-

The rest have single numbers stamped into them.

================================================

Since I haven't the foggiest idea I would like opinions/suggestions on how I should sell them, individually or as a set?

Thanks!

A few have markings:

st-5 1-24-5254

bridgeport

-=-

st-3 1-24-5252

bridgeport

7/79

-=-

The long one is stamped Cincinnati Milling Machine Co.

-=-

The rest have single numbers stamped into them.

================================================

Since I haven't the foggiest idea I would like opinions/suggestions on how I should sell them, individually or as a set?

Thanks!