- Joined

- Nov 23, 2014

- Messages

- 2,634

Like many others, my aging eyes like more light on the subject. I bought myself a Bridgeport mill as a birthday present (OK’d by my wife) and added a HALO Angel Eyes light to it this weekend.

I had ordered a pair of 100 mm lights off eBay some time back and used one on my Jet JVM-830 mill. Really nice to focus the light straight down the quill. I had one left over as they’re sold in pairs. Mine came with a light cover for protection which was just a little small to fit over the Bridgeport’s quill, so some mods were in order.

The light on my Jet is great, but could it be improved on the Bridgeport? Sure, did a little research and discovered the Angle Eyes lights come in many sizes. I ordered a pair of 110 mm lights so the 100 mm and 110 mm could be nested together.

Nesting the two lights together wiped out using the stock lens which wasn’t a big deal since the 100 mm lens didn’t fit anyhow. My BP has 2-axis CNC, so designed up a mounting ring for the 2 lights with a polycarbonate lens.

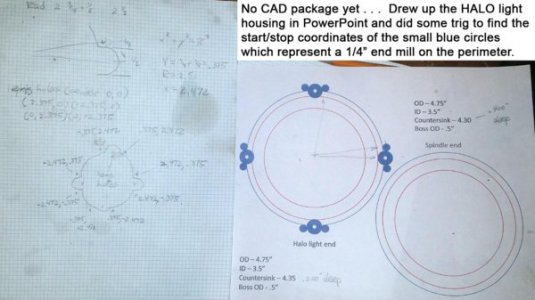

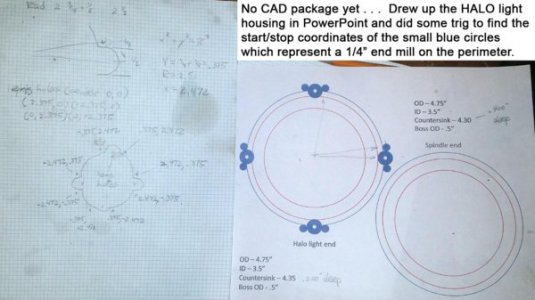

I’m looking forward to moving into the 21st century and running a CAD/CAM package someday. But until then, my programming is done via conversation or direct inputting of codes into the Anilam Crusader control box. I tend to write every routine as a subroutine with a unique label. That way multiple programs can be in memory and various ones run by CALLing the different routines at the start of the program memory. Another 21st century project will be figuring out how to dump to/from the control box too through the RS-232 port. May be a winter project . . .

Wrote the routine for cutting the perimeter with 4 bosses for lens screw holes, hole routine to clear out the center area and a routine to do a circular pocket to counterbore the middle. One side is counterbored for a recessed pocket for the lights, other side for a pocket to slip over the mill’s quill housing.

Ran the routines in air for starters, then ran them on a piece of particle board. I didn’t bother cutting the perimeter to full depth as it was just to prove out the routines anyhow.

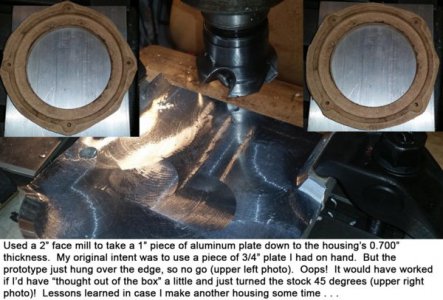

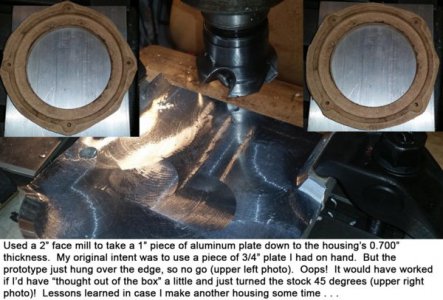

The light adapter is 0.700” thick; had a piece of ¾” aluminum all prepared for the job. But it was just a little narrow for the lens bosses so threw a 1” piece on the mill and face cut away. About 2/3 through the surfacing I had a “duh” moment. The ¾” piece would have worked fine if I put it on the table at a 45 angle instead of square, or re-wrote the perimeter routine to put the bosses at 45, 135, 225, 315 instead of 0, 90, 180, 270. Hung my head for a moment and moved on . . .

Made the test cuts in the particle board which showed me the side would need to be notched for the HALO light wires to feed through. Guess that’s why we build prototypes.

Ran the center hole cutting routine first. Bit of a pucker factor here as the routine starts at the center, then moves up in the 1:30 direction until it gets close to the circle. It then travels CCW until it’s on the path, then continues around to 12:00 where it starts to veer off the circle until 10:30, where it then diagonals back to the center. On the last pass, the center piece of aluminum came lose as expected but started to rotate. That meant the 10:30 to center move was going to be at a feed rate of 8 ipm at a full depth of cut (0.700”). Quickly hit the HOLD button on the CNC before things got ugly. Lessons learned is to either clamp down the center plug or block the work up so the plug falls down on the last path.

Ran the counterbore routine next and dry fit the HALO lights. Perfect fit other than the notching for wire routing. Drilled and tapped the boss holes next; used the CNC as a DRO and did it manually. One nice thing with my set up is I can plug in a coordinate and the table will rapid move (100 ipm) to that spot. So no hand turning of the cranks to get to my targets.

Ran the routine for the perimeter next. Manually milled the notch for the wires. Cut a block of wood and screwed it into the recessed pocket as a hold down; didn’t want a repeat of the center hole cutting excitement.

Flipped the housing over for counterboring the quill end. Used a co-ax indicator to center the work, then ran the circular pocket routine.

The lens was made from a piece of 0.080” clear polycarbonate. Clamped it to a block of wood and ran the same center hole cutting routine. Then drilled screw holes for bolting to the housing and finished it up with the perimeter cutting routine.

Next step was to make an insulator for the bottom of the lights as they set in the housing. Something about aluminum being a good conductor. Used the same center hole cutting routine and a circle cutting routine to cut the OD.

Drilled and tapped four 8-32 holes on the perimeter of the housing for set screws to attach the assembly to the quill housing. Then assembled the parts, used some Gorilla glue to tack the insulation and lights in place. Screwed the lens down and shot some clear RTV silicone in the wire exit hole to seal it up.

Fashioned a sheet metal bracket for mounting an ON/OFF switch which was attached to the Bridgeport auto-feed speed setting housing.

It works GREAT! The single HALO on my Jet mill is nice, but the doubled up ones on the Bridgeport are fantastic! Oh, they make 120 mm HALO lights too, maybe nest a 100, 110 and 120 together?

Bruce

I had ordered a pair of 100 mm lights off eBay some time back and used one on my Jet JVM-830 mill. Really nice to focus the light straight down the quill. I had one left over as they’re sold in pairs. Mine came with a light cover for protection which was just a little small to fit over the Bridgeport’s quill, so some mods were in order.

The light on my Jet is great, but could it be improved on the Bridgeport? Sure, did a little research and discovered the Angle Eyes lights come in many sizes. I ordered a pair of 110 mm lights so the 100 mm and 110 mm could be nested together.

Nesting the two lights together wiped out using the stock lens which wasn’t a big deal since the 100 mm lens didn’t fit anyhow. My BP has 2-axis CNC, so designed up a mounting ring for the 2 lights with a polycarbonate lens.

I’m looking forward to moving into the 21st century and running a CAD/CAM package someday. But until then, my programming is done via conversation or direct inputting of codes into the Anilam Crusader control box. I tend to write every routine as a subroutine with a unique label. That way multiple programs can be in memory and various ones run by CALLing the different routines at the start of the program memory. Another 21st century project will be figuring out how to dump to/from the control box too through the RS-232 port. May be a winter project . . .

Wrote the routine for cutting the perimeter with 4 bosses for lens screw holes, hole routine to clear out the center area and a routine to do a circular pocket to counterbore the middle. One side is counterbored for a recessed pocket for the lights, other side for a pocket to slip over the mill’s quill housing.

Ran the routines in air for starters, then ran them on a piece of particle board. I didn’t bother cutting the perimeter to full depth as it was just to prove out the routines anyhow.

The light adapter is 0.700” thick; had a piece of ¾” aluminum all prepared for the job. But it was just a little narrow for the lens bosses so threw a 1” piece on the mill and face cut away. About 2/3 through the surfacing I had a “duh” moment. The ¾” piece would have worked fine if I put it on the table at a 45 angle instead of square, or re-wrote the perimeter routine to put the bosses at 45, 135, 225, 315 instead of 0, 90, 180, 270. Hung my head for a moment and moved on . . .

Made the test cuts in the particle board which showed me the side would need to be notched for the HALO light wires to feed through. Guess that’s why we build prototypes.

Ran the center hole cutting routine first. Bit of a pucker factor here as the routine starts at the center, then moves up in the 1:30 direction until it gets close to the circle. It then travels CCW until it’s on the path, then continues around to 12:00 where it starts to veer off the circle until 10:30, where it then diagonals back to the center. On the last pass, the center piece of aluminum came lose as expected but started to rotate. That meant the 10:30 to center move was going to be at a feed rate of 8 ipm at a full depth of cut (0.700”). Quickly hit the HOLD button on the CNC before things got ugly. Lessons learned is to either clamp down the center plug or block the work up so the plug falls down on the last path.

Ran the counterbore routine next and dry fit the HALO lights. Perfect fit other than the notching for wire routing. Drilled and tapped the boss holes next; used the CNC as a DRO and did it manually. One nice thing with my set up is I can plug in a coordinate and the table will rapid move (100 ipm) to that spot. So no hand turning of the cranks to get to my targets.

Ran the routine for the perimeter next. Manually milled the notch for the wires. Cut a block of wood and screwed it into the recessed pocket as a hold down; didn’t want a repeat of the center hole cutting excitement.

Flipped the housing over for counterboring the quill end. Used a co-ax indicator to center the work, then ran the circular pocket routine.

The lens was made from a piece of 0.080” clear polycarbonate. Clamped it to a block of wood and ran the same center hole cutting routine. Then drilled screw holes for bolting to the housing and finished it up with the perimeter cutting routine.

Next step was to make an insulator for the bottom of the lights as they set in the housing. Something about aluminum being a good conductor. Used the same center hole cutting routine and a circle cutting routine to cut the OD.

Drilled and tapped four 8-32 holes on the perimeter of the housing for set screws to attach the assembly to the quill housing. Then assembled the parts, used some Gorilla glue to tack the insulation and lights in place. Screwed the lens down and shot some clear RTV silicone in the wire exit hole to seal it up.

Fashioned a sheet metal bracket for mounting an ON/OFF switch which was attached to the Bridgeport auto-feed speed setting housing.

It works GREAT! The single HALO on my Jet mill is nice, but the doubled up ones on the Bridgeport are fantastic! Oh, they make 120 mm HALO lights too, maybe nest a 100, 110 and 120 together?

Bruce

Last edited: