- Joined

- Oct 13, 2014

- Messages

- 9,684

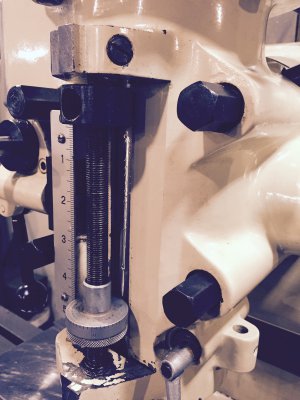

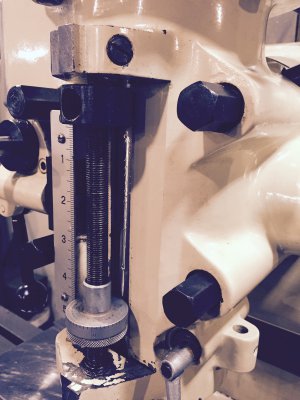

Today, while continuing the setup and contemplating the CNC conversion of my new mill, I decided to check the full range of all the axises. X 29.75", Y 12.25"... Then I turned the stop all the way south on the Z, pulled the quill lever, smooth all the way down Just about 5.25" of travel. Then I pushed the quill back and about halfway up CA-CHUNK dead stop! I moved the lever down-up again and again, it would not go past the same point, it was a solid metal to metal stop. I tried to engage and disengage the down-feed, no luck. I started to freak a bit thinking I somehow broke a tooth on the pinion gear or worse the rack on the quill! I never disassembled a B'port head or clone there of before, so it took me about two hours to get the quill out everything looked fine, not a chip or mark to be found. so I look up into the bore and see a "C" shaped cylinder wedged up near the top. I got it out and figured its the chip guard that covers the slot opening behind the depth adjuster... It must have come loose and jammed the quill. The way I see it working, It sits in a wider section, at the top of the bore, it has two tabs that catch under the heads of two screws 180 deg. apart in the top of the quill, when the quill is all the way up it slides inside the piece, when the quill is pulled down the tabs travel in two grooves milled in the side of the quill until they contact the screws then the quill pulls the piece down to cover the slot in the head. I guess the quill traveled too far down and bent the tabs on the piece straight then on the return, the screws hit the bottom of the taps preventing the quill from sliding inside and pushing it up till it hit the top of the bore. Okay problem solved, but not really because I could not figure a way to reassemble it without taking the top of the head apart... Well I didn't have the time to do that so just I put it back together without the piece.

So My questions to all you Variable -Speed Head Gurus:

1. Is the a way to install it without taking the upper head apart? (I know the answer but hope still prevails)?

2. How bad is it if I just leave the piece out?

3. Has this ever happened to anyone else?

4. is there a way to prevent it from happening again?

I greatly appricheate any help

Thanks

Eddy

So My questions to all you Variable -Speed Head Gurus:

1. Is the a way to install it without taking the upper head apart? (I know the answer but hope still prevails)?

2. How bad is it if I just leave the piece out?

3. Has this ever happened to anyone else?

4. is there a way to prevent it from happening again?

I greatly appricheate any help

Thanks

Eddy