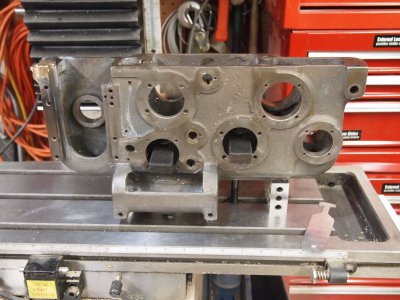

My 1941 Monarch 10EE apron has a broken corner of the main casting, which shows up in the photo on the upper left. I've never done brazing to build up a part, so I hired it out. The break left half the threads remaining for the bolt that secures that corner to the saddle. I left them there because I thought the welder would want as much of the apron intact to guide his work, and that he would grind them out as part of the preparation. He did not. Drilling the new hole went well, but threading was a touch-and-go situation. The new threads did not align with the remainder of the old ones, and I thought that the tap was going to break. The resulting threads are not great. But they do function to hold a bolt, so in the end, all is well.

I should have discussed my expectations more thoroughly with the welder. Don't be like me.

I should have discussed my expectations more thoroughly with the welder. Don't be like me.