The machine is a manual Super Max B'port clone.

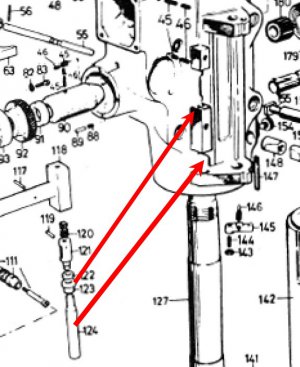

The spindle down feed works but I have a problem with the depth feed trip mechanism. It has started tripping before depth is reached and recently even before the cut has started. I have a users manual for the machine at the shop but apart from a parts list it is useless for figuring out how/what's wrong.

I spent some time fooling with it and found some things that might be clues.

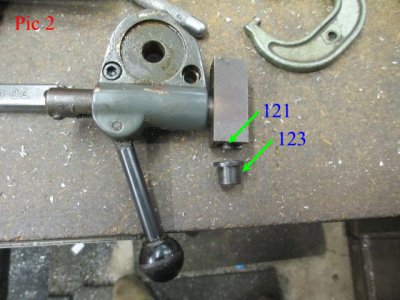

The actuating lever doesn't seem a solid when in is engaged or crisp when I disengage it manually.

The 1/2-2o rod that controls the feed depth doesn't have as much up and down play as I remember. In fact it has very little vertical movement.

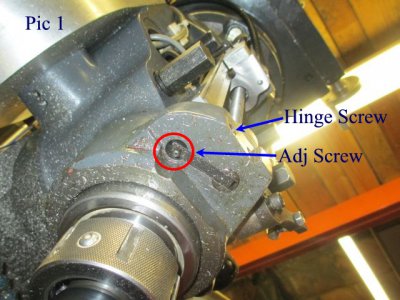

I fiddled with things, removed the large headed screw on the head that is above the afore mentioned depth control rod, behind it was a small rod that moves up when the spindle is up all the way and down by the action of gravity. It seemed to be stuck as it didn't drop by it's own weight. I put some penetrating oil in with it an it seemed to fix it but started acting up after while. I gave it another dose and decided to let it sit overnight.

Has anyone else encountered a similar problem?

Can anyone point me to an explanation of how the depth control mechanism works? Not how to set it but how it works.

Thanks

Lowell

The spindle down feed works but I have a problem with the depth feed trip mechanism. It has started tripping before depth is reached and recently even before the cut has started. I have a users manual for the machine at the shop but apart from a parts list it is useless for figuring out how/what's wrong.

I spent some time fooling with it and found some things that might be clues.

The actuating lever doesn't seem a solid when in is engaged or crisp when I disengage it manually.

The 1/2-2o rod that controls the feed depth doesn't have as much up and down play as I remember. In fact it has very little vertical movement.

I fiddled with things, removed the large headed screw on the head that is above the afore mentioned depth control rod, behind it was a small rod that moves up when the spindle is up all the way and down by the action of gravity. It seemed to be stuck as it didn't drop by it's own weight. I put some penetrating oil in with it an it seemed to fix it but started acting up after while. I gave it another dose and decided to let it sit overnight.

Has anyone else encountered a similar problem?

Can anyone point me to an explanation of how the depth control mechanism works? Not how to set it but how it works.

Thanks

Lowell