- Joined

- Dec 18, 2019

- Messages

- 7,429

Have a 2" boring head for my PM25. Took it out of the gloppy oil for the first time. It's sort of cleaned up now. I have 1/2" boring bars in HSS. It's pretty obvious they aren't ready yet for use. They are not sharp edged. My only frame of reference is lathe HSS tooling. Do I run them on a diamond hone on the surfaces to make the edges sharp? Where the edge should be one can see a bright line indicating it is flat and reflecting, not an edge.

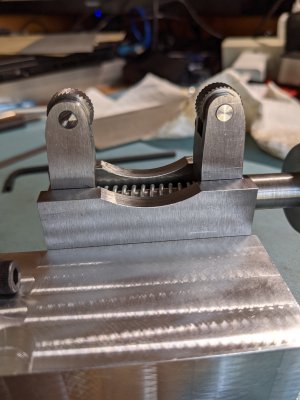

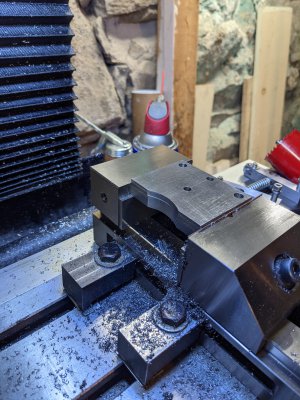

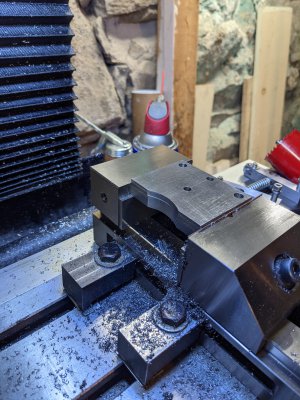

This boring came with no instructions. I understand the basics, but is there anything I should watch out for as a first time user? My first application is an interrupted cut in low carbon steel. I have cut an arc (less than a half moon) out of some plates with a hole saw. I want to slightly enlarge the hole and clean it up with the boring head. I understand tiny cuts, but anything else to be aware of?

Thanks for any tips and advice! That hole saw was really eccentric! Haven't seen anything that off balanced in a while. About 0.1" wobble. Fortunately it was all at low RPM. The cardboard in the vise prevented any lift or movement. The line you see is when I readjusted the hole saw, trying to make it less eccentric. Didn't help. If nothing else, I'd like to use the boring head to "erase" the line and make it even. Really don't have to remove much at this point, but I'd like to do it by machine so it is identical.

This boring came with no instructions. I understand the basics, but is there anything I should watch out for as a first time user? My first application is an interrupted cut in low carbon steel. I have cut an arc (less than a half moon) out of some plates with a hole saw. I want to slightly enlarge the hole and clean it up with the boring head. I understand tiny cuts, but anything else to be aware of?

Thanks for any tips and advice! That hole saw was really eccentric! Haven't seen anything that off balanced in a while. About 0.1" wobble. Fortunately it was all at low RPM. The cardboard in the vise prevented any lift or movement. The line you see is when I readjusted the hole saw, trying to make it less eccentric. Didn't help. If nothing else, I'd like to use the boring head to "erase" the line and make it even. Really don't have to remove much at this point, but I'd like to do it by machine so it is identical.