- Joined

- Jan 2, 2019

- Messages

- 7,125

Finally had a chance to check out the lathe as yesterday evening was spent helping our daughter with student loans for her masters program.

Stuff fits into one of three categories, bent, broken, and just needs improvement. There were a bunch of not very tight fasteners, I don't know if they were loosened at some point or just that way from the factory but I'm figuring the latter so everything needs to be checked over regardless of if it's busted or not.

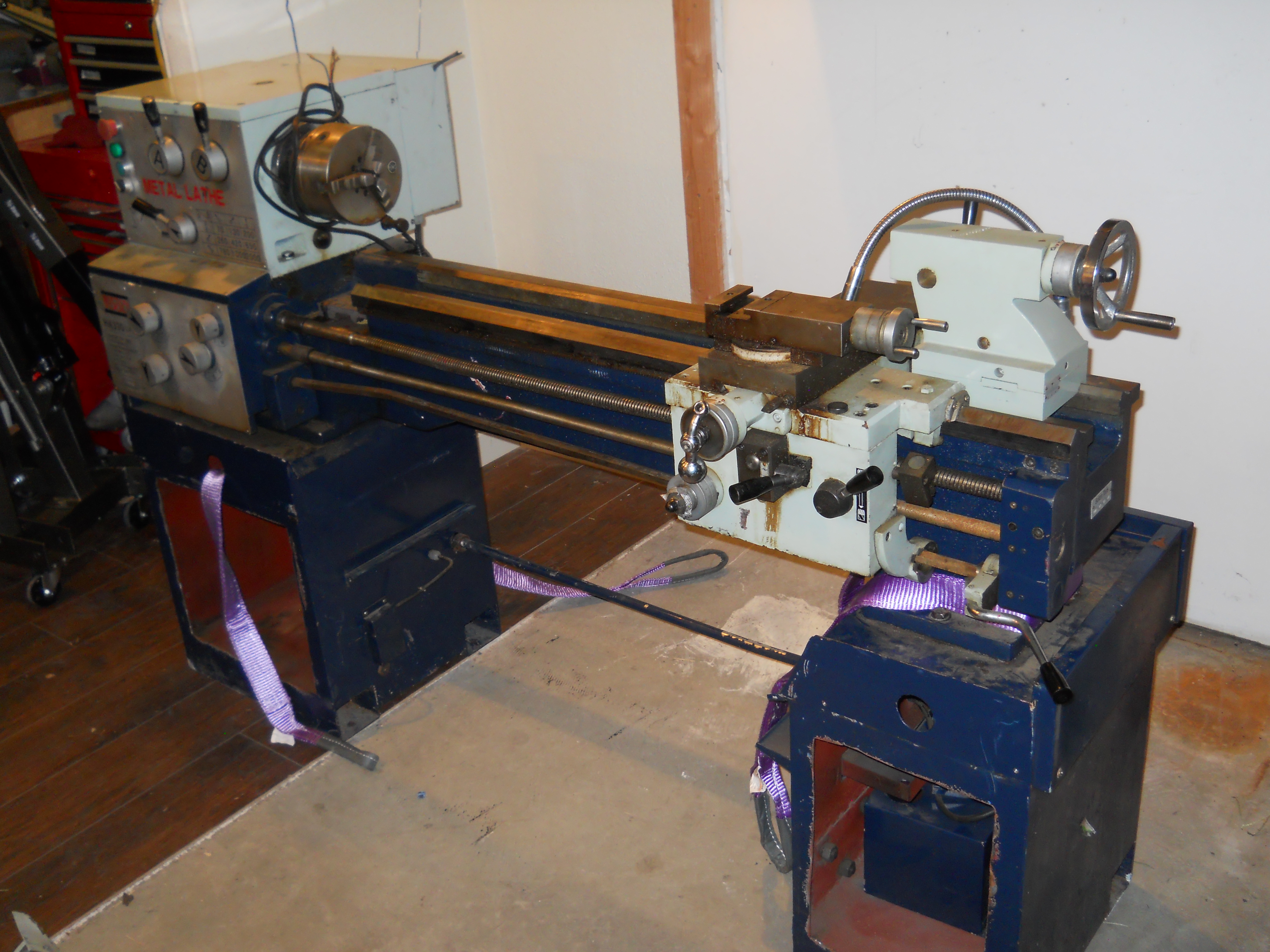

Here's the machine as it landed in my shop, surprisingly it's almost exactly the same color I painted the Craftsman that I traded for it.

First I pulled all the control rods.

I figure I can straighten these out with a little finesse, at least good enough to make replacements if needed. You can see the shaft sleeve is broken which is a part I may try to source from a similar machine.

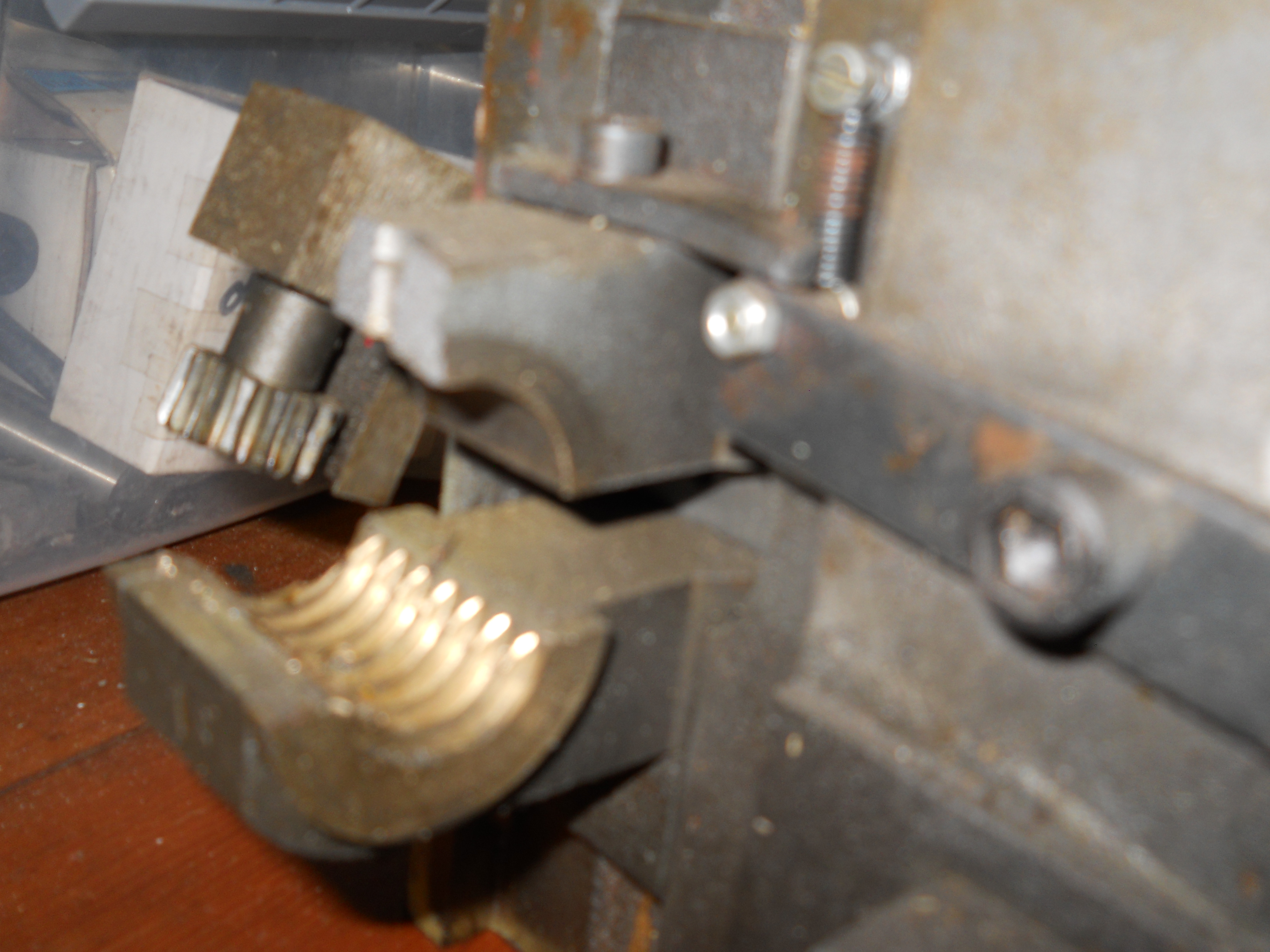

Then I pulled the apron and found a broken screw nut seat.

If the terms I'm using seem strange that's because I'm going from what the parts list calls them so I can hopefully cross-reference things.

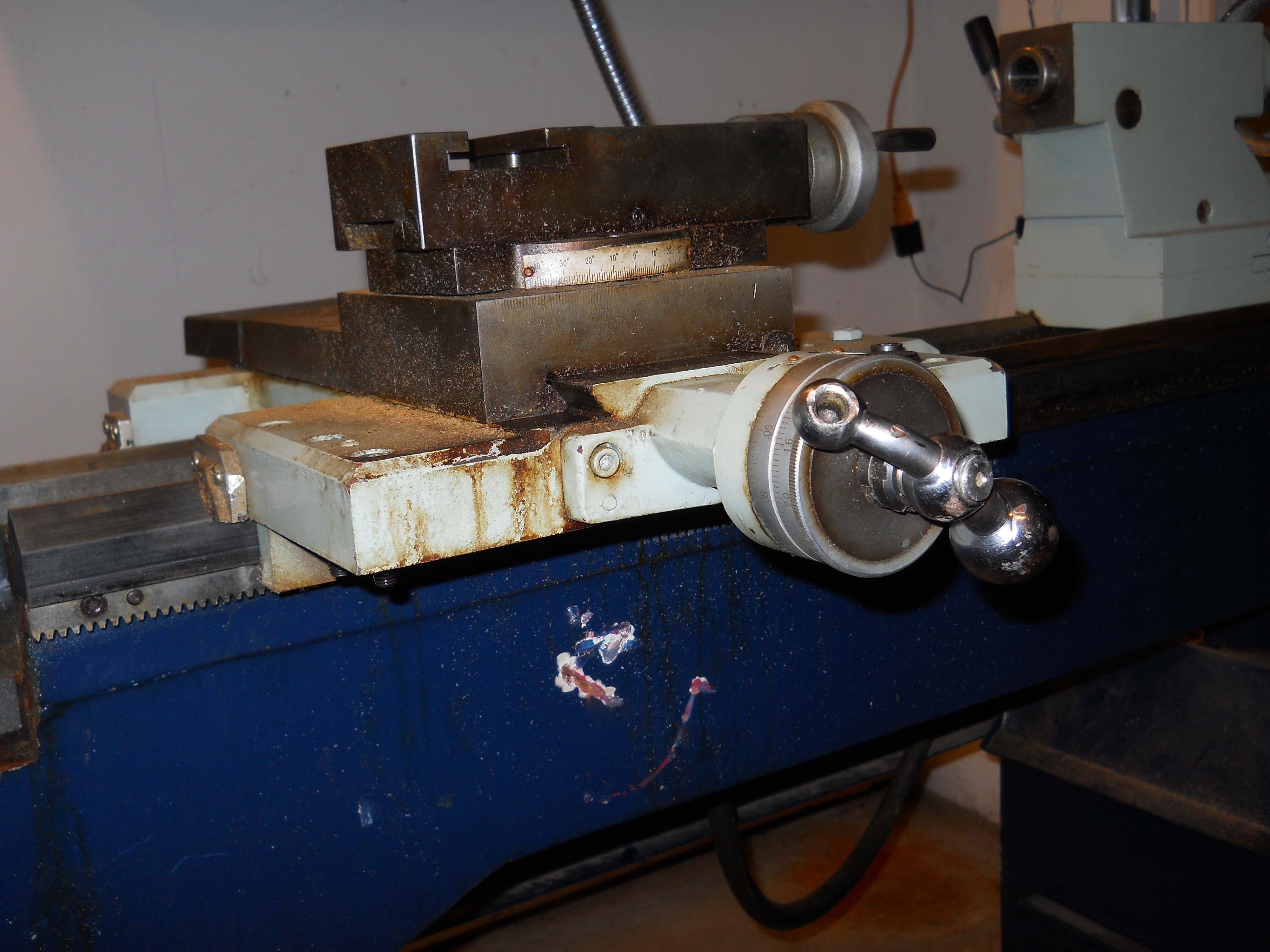

The cross slide screw is definitely bent but that may have to wait a while.

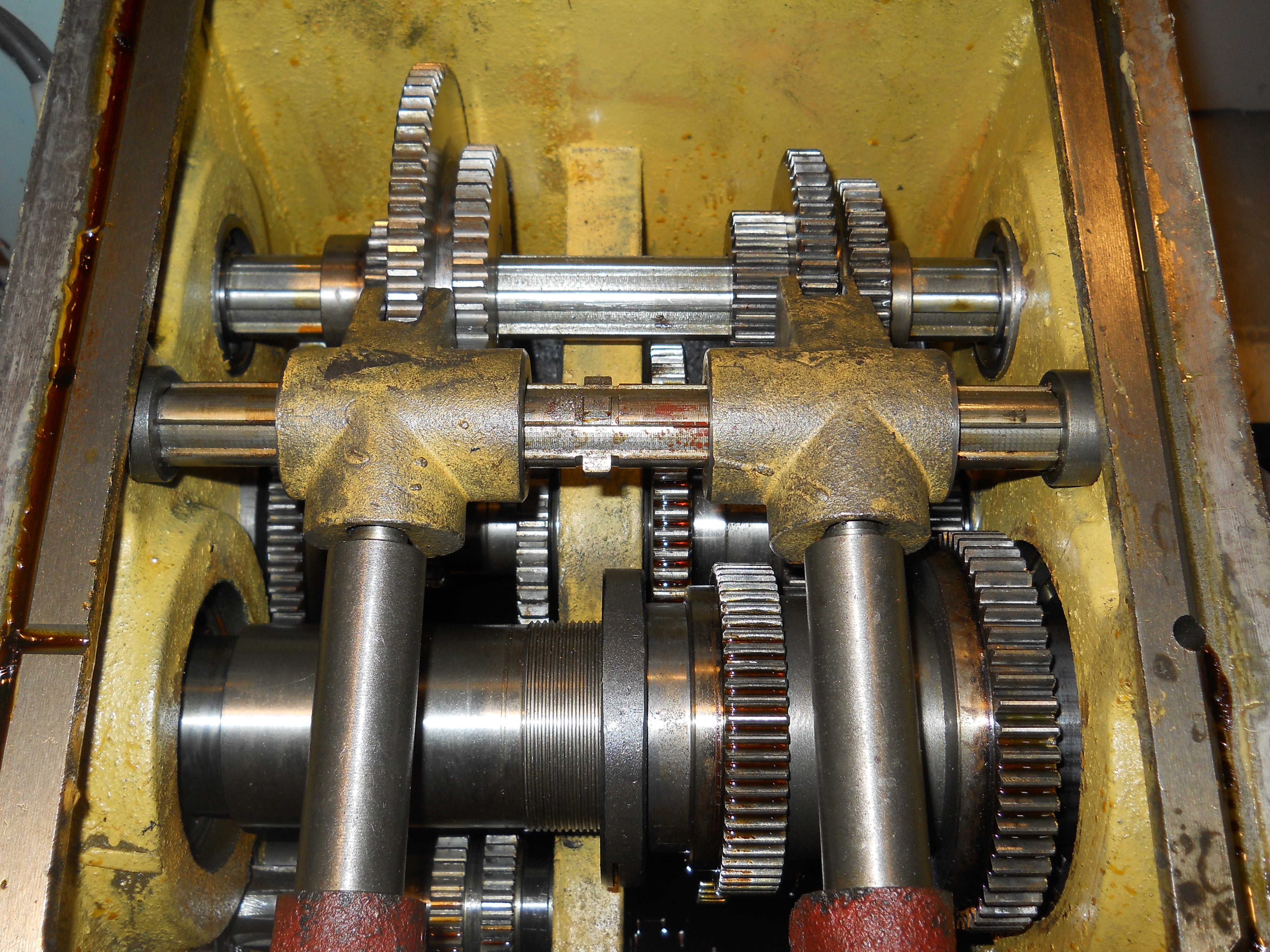

The gearbox seems fine.

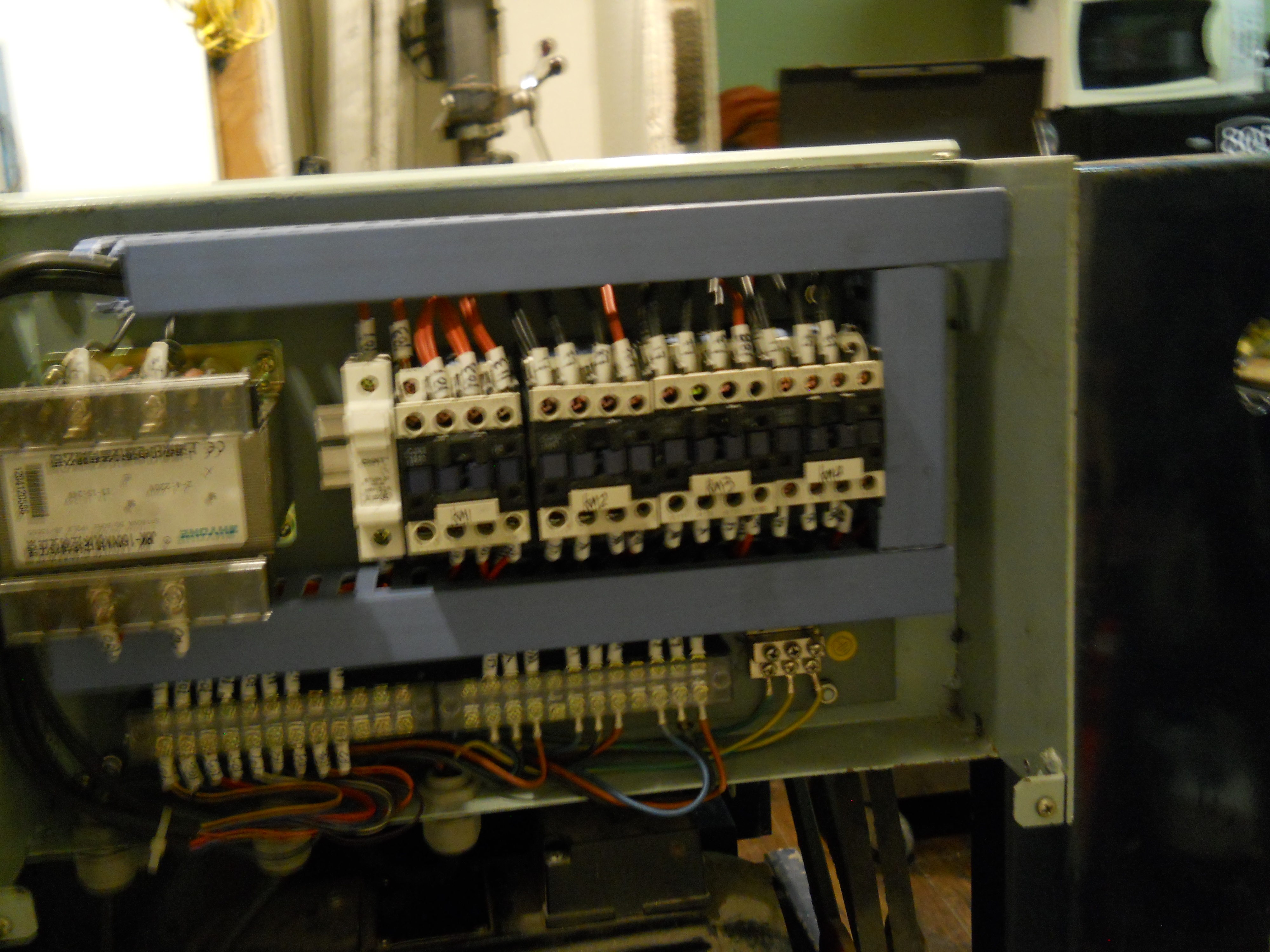

And the electrical looks good.

Of course the biggest issue is the gap which decided to separate and go for a tumble down the highway on the ride home.

@Aaron_W suggested JB Weld which I didn't think was such a great idea at the time but I am seriously considering some sort of epoxy, maybe the 3M Titanium stuff I used in my race engines.

Well, I definitely have some work ahead of me but I'm confident I can make it into a capable machine eventually. Please chime in if you have suggestions for other makes/models that may have similar parts, It looks like all the other 13 or 14 x 40's coming out of China. It was built in 2012 and from what I can tell it was never really used from new since it appears to still have the factory cosmoline on it's bed and other parts.

John

Stuff fits into one of three categories, bent, broken, and just needs improvement. There were a bunch of not very tight fasteners, I don't know if they were loosened at some point or just that way from the factory but I'm figuring the latter so everything needs to be checked over regardless of if it's busted or not.

Here's the machine as it landed in my shop, surprisingly it's almost exactly the same color I painted the Craftsman that I traded for it.

First I pulled all the control rods.

I figure I can straighten these out with a little finesse, at least good enough to make replacements if needed. You can see the shaft sleeve is broken which is a part I may try to source from a similar machine.

Then I pulled the apron and found a broken screw nut seat.

If the terms I'm using seem strange that's because I'm going from what the parts list calls them so I can hopefully cross-reference things.

The cross slide screw is definitely bent but that may have to wait a while.

The gearbox seems fine.

And the electrical looks good.

Of course the biggest issue is the gap which decided to separate and go for a tumble down the highway on the ride home.

@Aaron_W suggested JB Weld which I didn't think was such a great idea at the time but I am seriously considering some sort of epoxy, maybe the 3M Titanium stuff I used in my race engines.

Well, I definitely have some work ahead of me but I'm confident I can make it into a capable machine eventually. Please chime in if you have suggestions for other makes/models that may have similar parts, It looks like all the other 13 or 14 x 40's coming out of China. It was built in 2012 and from what I can tell it was never really used from new since it appears to still have the factory cosmoline on it's bed and other parts.

John