- Joined

- Nov 9, 2018

- Messages

- 377

It would appear that the OEM Timken bearings on my Clausing 5428 are “standard precision”. Spoke with Clausing on the phone, and the bearing numbers they gave me are identical to many automotive bearings.

Using the original bearings, with some rear journal damage, I measured TIR inside the spindle bore, in the taper, outside the spindle, on the chuck mounting flange, and by the rear bearing, on the spindle shaft itself. I measure a TIR of around 1-2 tenths.

I’m not very well versed in the different bearing classes and tolerances.

On a medium duty, and medium precision lathe like the Clausing 5400, is there any advantage to going with the “precision” class bearings. The cost difference is massive, I got the standard precision ones for about $130, open box on eBay. But the precision class bearings, even open box would bump the cost up to around $1000 for the races and cones.

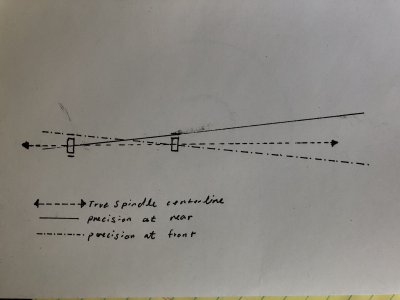

A related question, is it possible to measure bearing TIR with V-blocks and surface plate? I’d like to orient or ‘clock’ the two cone bearings so the out of round is in phase, i.e. to minimize spindle wobble. It’s much easier to compensate for a uniform runout parallel to the rotation axis than a wobble.

I did get lucky and found one precision class bearing race as an open box, I’ll fit that on the chuck side of the spindle.

Using the original bearings, with some rear journal damage, I measured TIR inside the spindle bore, in the taper, outside the spindle, on the chuck mounting flange, and by the rear bearing, on the spindle shaft itself. I measure a TIR of around 1-2 tenths.

I’m not very well versed in the different bearing classes and tolerances.

On a medium duty, and medium precision lathe like the Clausing 5400, is there any advantage to going with the “precision” class bearings. The cost difference is massive, I got the standard precision ones for about $130, open box on eBay. But the precision class bearings, even open box would bump the cost up to around $1000 for the races and cones.

A related question, is it possible to measure bearing TIR with V-blocks and surface plate? I’d like to orient or ‘clock’ the two cone bearings so the out of round is in phase, i.e. to minimize spindle wobble. It’s much easier to compensate for a uniform runout parallel to the rotation axis than a wobble.

I did get lucky and found one precision class bearing race as an open box, I’ll fit that on the chuck side of the spindle.