My Emco FB2 mill is out of tram by 0.05 mm over 150 mm along the Y axis. Negligible along the X axis ( adjustable ). I performed a face milling operation with the following parameters :

material : hot roll steel ( called "A3" by the vendor )

tool : 10 mm carbide end mill

rpm : 1100

travel direction of the tool : back and forth along the Y axis

cutting fluid : nil

depth of cut : 0.1 mm

overlapping between neighboring passes : 2 mm

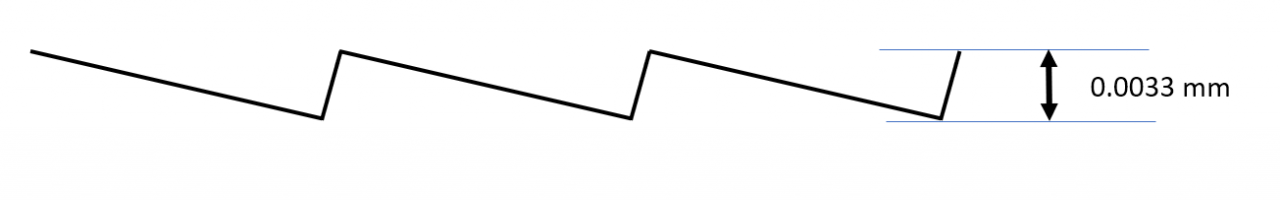

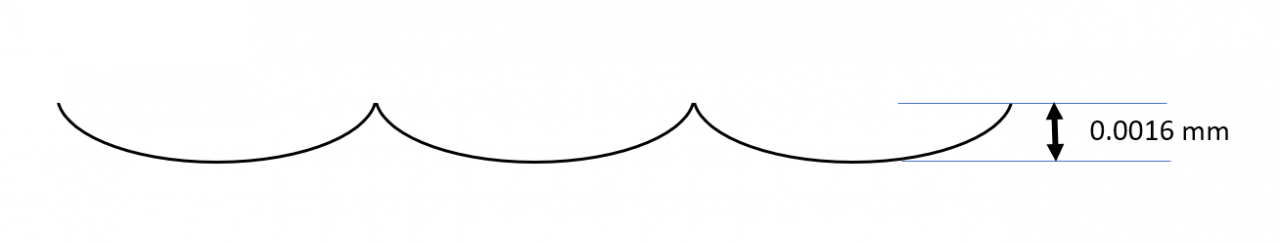

The result is shown in the photo. As expected, the machining marks are series of arcs instead of complete circles due to the imperfect tram but my question is not about the finish but the flatness of the surface.

As the tool is not perfectly perpendicular to the table, I would expect the tool to dig slightly deeper into the metal at the center so the surface cut out by each pass should be slightly concave having the two sides higher than the center. I checked that by inking the machined surface with a marker pen and rubbing the surface with the base of my vice ( should be very flat ) and the result indicates that the opposite is true, ie, the sides are lower ( ink not rubbed off ). Just wondering if I am missing something here. Any comments ?

What I am trying to do at the end is to make a wedge shim having the surfaces as flat as possible with my out-of-tram mill and subsequently use the shim to fix the misalignment problem ( more details in this thread ).

material : hot roll steel ( called "A3" by the vendor )

tool : 10 mm carbide end mill

rpm : 1100

travel direction of the tool : back and forth along the Y axis

cutting fluid : nil

depth of cut : 0.1 mm

overlapping between neighboring passes : 2 mm

The result is shown in the photo. As expected, the machining marks are series of arcs instead of complete circles due to the imperfect tram but my question is not about the finish but the flatness of the surface.

As the tool is not perfectly perpendicular to the table, I would expect the tool to dig slightly deeper into the metal at the center so the surface cut out by each pass should be slightly concave having the two sides higher than the center. I checked that by inking the machined surface with a marker pen and rubbing the surface with the base of my vice ( should be very flat ) and the result indicates that the opposite is true, ie, the sides are lower ( ink not rubbed off ). Just wondering if I am missing something here. Any comments ?

What I am trying to do at the end is to make a wedge shim having the surfaces as flat as possible with my out-of-tram mill and subsequently use the shim to fix the misalignment problem ( more details in this thread ).

Attachments

Last edited: