- Joined

- May 7, 2020

- Messages

- 267

We picked up a used Baileigh 6x78 belt grinder a few weeks ago. Brand new, commercial size grinders are stupid expensive...this one has some miles on it but seems to work fine. And Baileigh has parts support. What we didn't have was a good way to set it up. It is a no-no to drill into post tension concrete foundations and I really don't want holes in my garage floor anyway.

We'll set up the grinder next to our downdraft table / grinding station. Not luxurious but roomy enough. There will be cases where we want to move this thing and at 270 lbs wheels were a must.

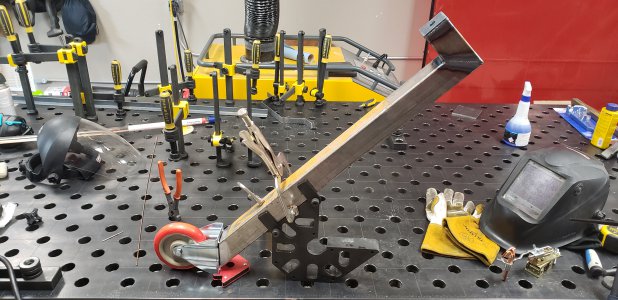

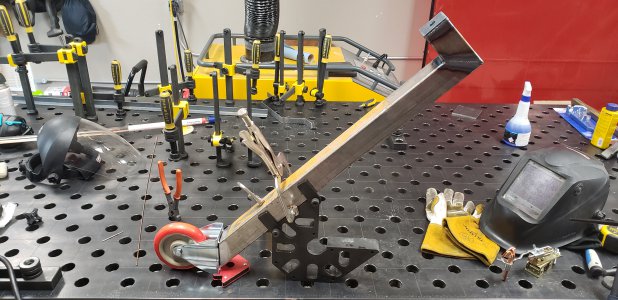

Frame rail with fixed caster and leveler. Love the Fireball Tool fixtures for welding. So versatile. Check them out (and their YouTube videos are great if you haven't seen them).

Pretty easy fabrication. Not done yet - we'll add a sort of wheelbarrow handle for lifting so we can move the grinder on the back wheels. After that we'll paint.

This will be a nice addition to the shop for weld prep, mostly beveling and removing mill scale from metal stock.

We'll set up the grinder next to our downdraft table / grinding station. Not luxurious but roomy enough. There will be cases where we want to move this thing and at 270 lbs wheels were a must.

Frame rail with fixed caster and leveler. Love the Fireball Tool fixtures for welding. So versatile. Check them out (and their YouTube videos are great if you haven't seen them).

Pretty easy fabrication. Not done yet - we'll add a sort of wheelbarrow handle for lifting so we can move the grinder on the back wheels. After that we'll paint.

This will be a nice addition to the shop for weld prep, mostly beveling and removing mill scale from metal stock.

Last edited: