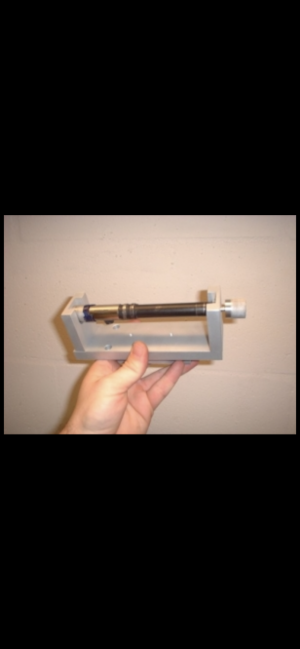

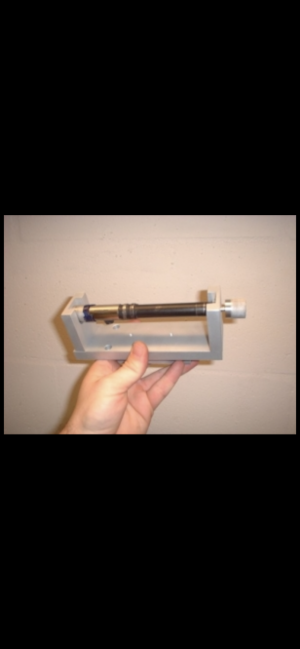

If you are going to multiple pieces, I would ask someone in the group to make one for you. It is a very simple setup. The only question is how to determine degrees of rotation. One of them uses a dial on the out side of the fixture, I guess with a decal showing degrees.

If you are only go to do this once or twice, you can make the device out of wood. On the left side support drill a hole for a dowel. Turn the end of the dowel down enough to push into the barrel snugly. On the outside make a groove in the end for reference. Make your own decal.

Middle of the barrel, make a barrel holding clamp. A piece of wood with the right size diameter hole, cut in half and screwed together.

Right side, drill a hole for dowel with tapered end, shove in the barrel, and tighten so it stays in place.

In use, place the barrel on the snug dowel and insert so the groove points at 0. Shove the tapered in through the right side support, into the barrel and fasten in place. You just want it to be able to turn with decent hand pressure. Now the whole trick with this setup is to get the jeweled section, level under the drill chuck. That is the only important part of this setup. May have to plane or shim to get the right angle.

The wooden barrel clamp only needs to fit between the barrel and the jig. It can be a tad smaller so there is clearance from clamp to bottom board. A shim will stop it from rotating. You clamp the barrel with pointer at 0 and check to see it doesn't move. Jewel the first row and loosen clamp. Rotate X degrees and re-clamp.

This is as Redneck, Back Yard, Shade Tree as it gets, but it will work since I have down some weird holders like this in the past. Best part is that it can be done in and hour or so with some scrap materials at hand. Nothing stops you from making a really nice adjustable, sliding one out of oak and getting someone to turn some tapered ends out of metal.

FYI. I'm making the same thing for clamping clarinet bodies to do milling operations. I have a commercial fixture with two tapered ends that go into the body ends. I am making an adjustable clamp that will keep the body from rotating with precision adjustment. That will allow me to reduce the pressure of the tapered ends going into the barrel but still lock the body in place under the spindle. It's called a clarinet tone hole jig. My wife's is about 40 years old and she never used it. I'm starting to do machine operations on junk clarinet bodies for practice.

PM me if you have questions or want a sketch.