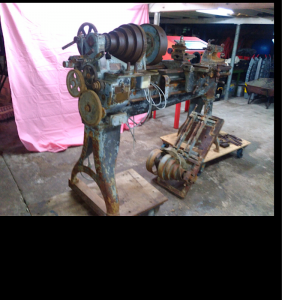

Hi well all together now, I’m using a little 1/3 hp motor to run her until my new 2hp 4pole 1400rpm motor arrives I even did a little turning today I made some thrust bushes out of pvc just so I got the sizes correct before ordering or making a new set from bronze it’s for the headstock the original were a fibre like material and they had collapsed before I acquired the lathe.

I made a new 1/2 split nut for screw cutting and that works well and the power feed works after I cleaned the engage clutch

And she has a new colour, she is now machinery grey epoxy enamel with black.

I gave her a good oil and can’t believe how well she runs, a little noisy with the gear train engaged, the tumbler gears make the most noise being straight cut gears, a fellow restorer sent me a video, he has the same lathe, so I could compare the noise and they sound very similar, I don’t know how they run a shop with lineshafts and dozens of machines in the past it must have been deafening, so I gave myself a year or two to get her working but she drove me hard and completed her in months not years I very pleased with the out come, a little bit of history lives again Craig