- Joined

- Nov 10, 2013

- Messages

- 837

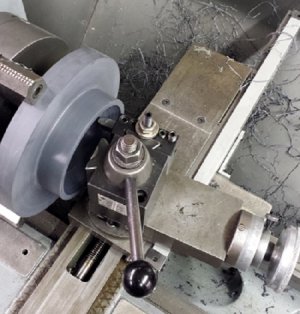

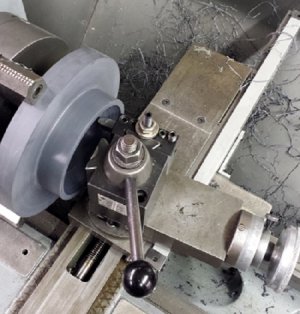

I picked up a ball vise Saturday that was missing the base and the chuck key. It was pretty rusted so I glass beaded it and rubbed it down with some scotchbrite. Today I turned a base out of PVC. I wouldn't normally post something so mundane but there was a thread last week where someone wanted to know how to cut a large radius without a radius tool. This one is a 2.75" radius. I put a HSS bit with a large radiused cutting edge in a tool holder and loosened the compound retaining nuts so I could rotate it by hand. The radius size is adjusted with the compound screw. I ran the spindle in reverse since I was only cutting on the far side of the part. I blued up the ball and tested the fit before I pulled it off the machine.

Last edited: