- Joined

- Jan 2, 2019

- Messages

- 7,161

So, my 13x40 Bolton lathe has an unusual DIN 55027 spindle mounting that took me a while to figure out what it was. They seem to be more common in Germany or maybe even Russia but pretty much rare as hen's teeth here in the states. I did get a quote on a Rohm part but it was over $600 for one backplate shipped over from Germany. So, what I ended up doing was buying three A1-5 A5 Rapidhold backplates off eBay for $100/ea. I figured the taper was the same so I could make it work somehow. Somehow was today....

Stock Bolton chuck on the right, A1-5 on the left, yes the drive cog is in the wrong place but I can fix that if it ever seems necessary. The taper should hold fine for my use.

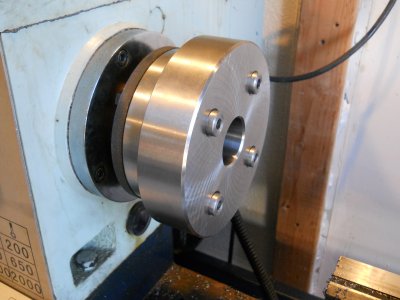

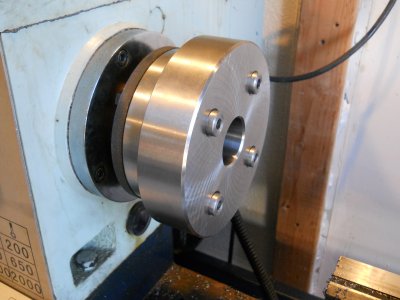

Turned some 1144 to the external dimensions I needed,

Drilled it through and parted it with my coldsaw since I don't have a parting blade yet.

Tapped it to 10mm x 1.5

Inserted on the front side of the backplate

Cut and tapped the mounting lugs the same way and cut some allthread to length and bolted it up. Now I'm ready for a 4 jaw, an ER collet chuck, and something else I haven't decided on yet.

John

Stock Bolton chuck on the right, A1-5 on the left, yes the drive cog is in the wrong place but I can fix that if it ever seems necessary. The taper should hold fine for my use.

Turned some 1144 to the external dimensions I needed,

Drilled it through and parted it with my coldsaw since I don't have a parting blade yet.

Tapped it to 10mm x 1.5

Inserted on the front side of the backplate

Cut and tapped the mounting lugs the same way and cut some allthread to length and bolted it up. Now I'm ready for a 4 jaw, an ER collet chuck, and something else I haven't decided on yet.

John