- Joined

- Aug 29, 2019

- Messages

- 723

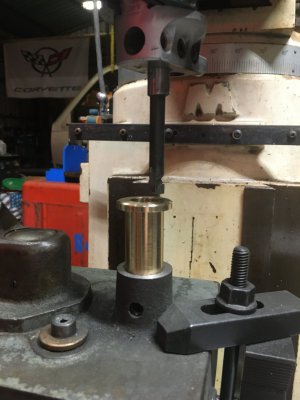

I finally got the bushing for the Apron hand wheel ready to press in. My question is .002 press too much for cast iron and bronze. I am beginning to think the bronze is maybe Ampco cause my horizontal band saw just did not want to saw it. I finally used a HSS parting tool and faced the remainder off with carbide. Would have been nice if I had the correct size stock so I didn't turn so many chips but that is what happens in Poor Folk USA. If necessary, I will skim another .001 off the O/D. For now, here are some pictures.

Attachments

-

IMG_3209.JPG494.9 KB · Views: 19

IMG_3209.JPG494.9 KB · Views: 19 -

IMG_3154.JPG234.8 KB · Views: 17

IMG_3154.JPG234.8 KB · Views: 17 -

IMG_3197.JPG520.1 KB · Views: 16

IMG_3197.JPG520.1 KB · Views: 16 -

IMG_3198.JPG540.8 KB · Views: 14

IMG_3198.JPG540.8 KB · Views: 14 -

IMG_3199.JPG298.4 KB · Views: 14

IMG_3199.JPG298.4 KB · Views: 14 -

IMG_3200.JPG265.6 KB · Views: 13

IMG_3200.JPG265.6 KB · Views: 13 -

IMG_3201.JPG469.5 KB · Views: 13

IMG_3201.JPG469.5 KB · Views: 13 -

IMG_3202.JPG487.2 KB · Views: 15

IMG_3202.JPG487.2 KB · Views: 15 -

IMG_3203.JPG266.6 KB · Views: 17

IMG_3203.JPG266.6 KB · Views: 17 -

IMG_3204.JPG234 KB · Views: 17

IMG_3204.JPG234 KB · Views: 17 -

IMG_3205.JPG203.9 KB · Views: 15

IMG_3205.JPG203.9 KB · Views: 15 -

IMG_3206.JPG217.7 KB · Views: 14

IMG_3206.JPG217.7 KB · Views: 14 -

IMG_3207.JPG624.4 KB · Views: 14

IMG_3207.JPG624.4 KB · Views: 14 -

IMG_3208.JPG478 KB · Views: 17

IMG_3208.JPG478 KB · Views: 17

Use a 3 prong hone if the ID shrinks .

Use a 3 prong hone if the ID shrinks .