- Joined

- Jan 22, 2014

- Messages

- 578

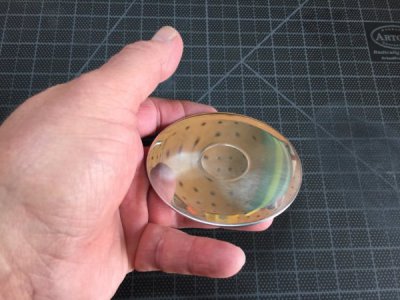

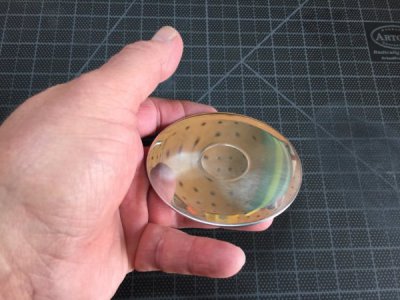

My latest project is my interpretation of Aztec or American Indian art; sun, rays, mountains and the 4 seasons. Anyway, it was a challenging project and could be used for a belt buckle, hat band or scarf cinch.

The materials I used are billet of 3.5” 6061 aluminum and a 1.5” bar of brass. I chose the brass for a contrasting inlay piece. After I drilled and parted off what could be described as a .060” washer, I made a jig to hold it while I cut the slots with a 5/8”chamfering bit on the rotary table (RT) on a compound angle to give them a variable width.

I used multiple, stepped angles with the compound slide on the lathe to shape the top of the aluminum body into a dome for a 3-D effect, then parted it off. I mounted it in the RT and cut the center (nipple) with a ½” radius cutter. I used the RT w/Angle Plate set to 10* along with the chamfering bit to make the various pictorial cuts. This gave them variable widths/depths adding to the 3-dD effect. Once I finished the top, I milled off the back side down and finished shaping it with the compound slide in the lathe providing a 2* concave finish. NOTE: At no time did I ever hold the piece by the outer diameter.

I polished everything in steps to a 5000 grit finish and then buffed it out with my 10” cotton wheels. First with Tripoli compound and then White Diamond. The thinned back side made for a very light piece. What started out in a few ounces ended up weighing just a few grams.

Grizzly G0602

LMS Hi Torque Mini Mill w/power feed

Rotary Table w/ Adjustable Angle Plate

The materials I used are billet of 3.5” 6061 aluminum and a 1.5” bar of brass. I chose the brass for a contrasting inlay piece. After I drilled and parted off what could be described as a .060” washer, I made a jig to hold it while I cut the slots with a 5/8”chamfering bit on the rotary table (RT) on a compound angle to give them a variable width.

I used multiple, stepped angles with the compound slide on the lathe to shape the top of the aluminum body into a dome for a 3-D effect, then parted it off. I mounted it in the RT and cut the center (nipple) with a ½” radius cutter. I used the RT w/Angle Plate set to 10* along with the chamfering bit to make the various pictorial cuts. This gave them variable widths/depths adding to the 3-dD effect. Once I finished the top, I milled off the back side down and finished shaping it with the compound slide in the lathe providing a 2* concave finish. NOTE: At no time did I ever hold the piece by the outer diameter.

I polished everything in steps to a 5000 grit finish and then buffed it out with my 10” cotton wheels. First with Tripoli compound and then White Diamond. The thinned back side made for a very light piece. What started out in a few ounces ended up weighing just a few grams.

Grizzly G0602

LMS Hi Torque Mini Mill w/power feed

Rotary Table w/ Adjustable Angle Plate