- Joined

- Feb 2, 2013

- Messages

- 3,957

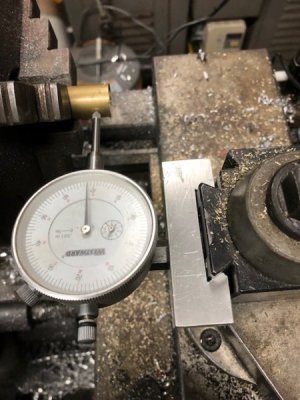

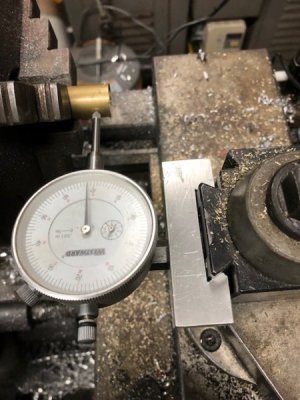

i got the idea to make my own dial indicator holder for my AXA toolposts

i have an modest abundance of 2" square solid 6061 aluminum in different lengths up to 5' long

it has holes and tapped holes from when it was in service as meat processing equipment,

so i cut it into differing lengths trying to find pieces without holes.

i use my Delta 10" saw with a 60 t carbide blade and wax as a lubricant.

often times the dimensions of the aluminum i'm trying to reduce is beyond the safe holding capabilities of my hands.

rather than losing a digit or 2, i have pondered different ways of holding the materials in the trusted saw.

, it hits me

, it hits me

drill and tap the deck of my saw to accept small toe clamps.

by chance i had some 1/4"-20 x 2-1/2" bolts that worked perfectly to anchor the toe clamps

then i had to further reduce the billet by 1/2" lengthwise.

so i rotated the billet 90° and clamped the piece once again.

after that hurdle i cut the dovetail by reducing the center section of the dovetail with a 5/8" 2 flute endmill at roughly .040" DOC per pass

i finished the dovetail with a carbide inserted dovetail cutter made by Randy Richards.

i constructed a standoff from 1/2" Hex 12L14, threaded at both ends male 1/4"-20 tpi to 1/2", drilled and tapped the indicator holder to 1/4"-20 TPI.

i turned and knurled a brass nut and brass washer to permit use on either axis by removing and rotating the indicator and replacing the nut

i'm considering adding an adjustment screw,

but i kinda like the flexibility of just holding it where i want it then clamping it there

Thanks for reading !

i have an modest abundance of 2" square solid 6061 aluminum in different lengths up to 5' long

it has holes and tapped holes from when it was in service as meat processing equipment,

so i cut it into differing lengths trying to find pieces without holes.

i use my Delta 10" saw with a 60 t carbide blade and wax as a lubricant.

often times the dimensions of the aluminum i'm trying to reduce is beyond the safe holding capabilities of my hands.

rather than losing a digit or 2, i have pondered different ways of holding the materials in the trusted saw.

drill and tap the deck of my saw to accept small toe clamps.

by chance i had some 1/4"-20 x 2-1/2" bolts that worked perfectly to anchor the toe clamps

then i had to further reduce the billet by 1/2" lengthwise.

so i rotated the billet 90° and clamped the piece once again.

after that hurdle i cut the dovetail by reducing the center section of the dovetail with a 5/8" 2 flute endmill at roughly .040" DOC per pass

i finished the dovetail with a carbide inserted dovetail cutter made by Randy Richards.

i constructed a standoff from 1/2" Hex 12L14, threaded at both ends male 1/4"-20 tpi to 1/2", drilled and tapped the indicator holder to 1/4"-20 TPI.

i turned and knurled a brass nut and brass washer to permit use on either axis by removing and rotating the indicator and replacing the nut

i'm considering adding an adjustment screw,

but i kinda like the flexibility of just holding it where i want it then clamping it there

Thanks for reading !