- Joined

- Jun 20, 2022

- Messages

- 235

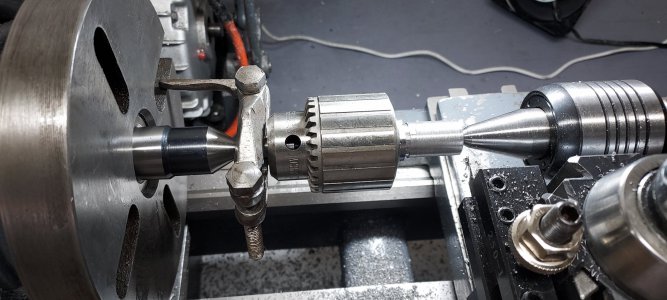

I needed a stubby 1/2" straight shank drill chuck for my round column mill (same shank as a center/edge finder, if you have a round column you probably understand why this is helpful). Bought a NOS Jacobs 32 off E-Bay for $25. It has 1/2-20 threads. Started to think "I should make an arbor myself, and make one that reduces runout in the chuck." I believe I was _mostly_ successful at doing so, and therefore figure the group might get something out of this, or possibly add some ideas how to do this easier or better.

Steps........

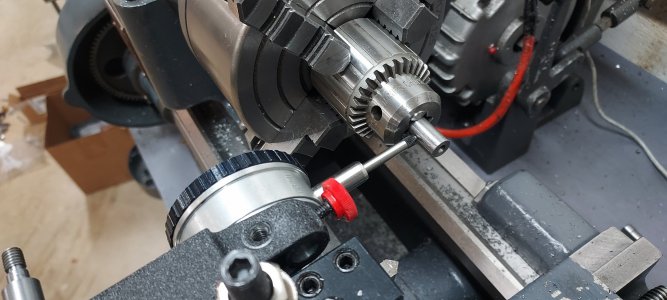

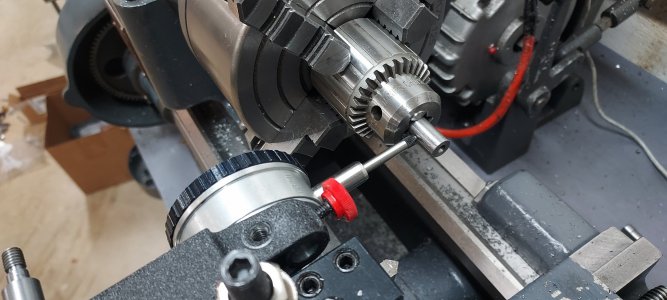

1) Cut 1/2-20 threads in a piece of 3/4" 1144 stressproof. Mount chuck in situ on the lathe and check runout with a ground rod......about .009" to .010" TIR

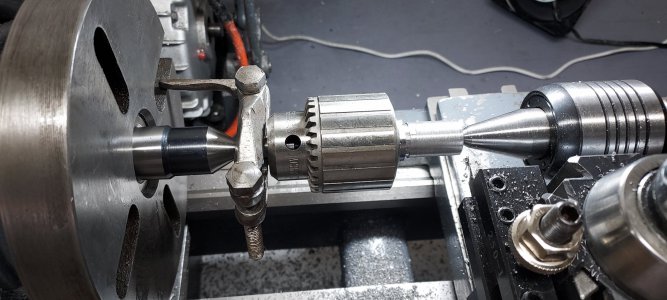

2) Turn a piece of 3/8" scrap. Mount it in the drill chuck in a 4 jaw chuck. Dial in the 4 jaw so the rod, not the drill chuck is running true. Center drill the 3/8" scrap and LEAVE IT IN PLACE AS IS FOR ALL REMAINING STEPS.

3) Cut off arbor, mill flats for 5/8" wrench in the 3/4" collar. Face and center drill the back of the arbor. Mount the arbor on the drill chuck.

4) At this point I have center drills on both ends. I then turn the 3/4" shank down to 1/2" between centers. I check for taper, adjust tailstock, and cut the shank down to 1/2" I should say.

The hoped for result being that the 1/2" shank will be concentric to the jaws of the drill chuck, NOT to the threads on the back of the chuck.

-----------------------------

The result: With various sized ground rods mounted in the chuck in an R-8 collet on my mill I measure between .0015 to .003" TIR. So I think I actually made a substantial improvement. My lathe bed has some twist so possibly the TIR is due to center drilling the temporary center slightly off due to the twist, or possibly drill chuck jaws just don't repeat no matter what you do. In either case I turned a piece of leftover 1144 into an arbor........

Steps........

1) Cut 1/2-20 threads in a piece of 3/4" 1144 stressproof. Mount chuck in situ on the lathe and check runout with a ground rod......about .009" to .010" TIR

2) Turn a piece of 3/8" scrap. Mount it in the drill chuck in a 4 jaw chuck. Dial in the 4 jaw so the rod, not the drill chuck is running true. Center drill the 3/8" scrap and LEAVE IT IN PLACE AS IS FOR ALL REMAINING STEPS.

3) Cut off arbor, mill flats for 5/8" wrench in the 3/4" collar. Face and center drill the back of the arbor. Mount the arbor on the drill chuck.

4) At this point I have center drills on both ends. I then turn the 3/4" shank down to 1/2" between centers. I check for taper, adjust tailstock, and cut the shank down to 1/2" I should say.

The hoped for result being that the 1/2" shank will be concentric to the jaws of the drill chuck, NOT to the threads on the back of the chuck.

-----------------------------

The result: With various sized ground rods mounted in the chuck in an R-8 collet on my mill I measure between .0015 to .003" TIR. So I think I actually made a substantial improvement. My lathe bed has some twist so possibly the TIR is due to center drilling the temporary center slightly off due to the twist, or possibly drill chuck jaws just don't repeat no matter what you do. In either case I turned a piece of leftover 1144 into an arbor........

Last edited: