- Joined

- Jan 25, 2015

- Messages

- 2,558

You may have already seen where my top slide broken during a parting operation: https://www.hobby-machinist.com/threads/aww-fudge-busted-my-th42-compound-slide.76225/

Then a thread to build a top slide: https://www.hobby-machinist.com/threads/building-an-atlas-th42-compound-slide.76253/

Well, now a thread to modify the Atlas milling attachment so i can make a top slide.

Yeesh, it never ends! Make a tool, to make a tool, to make a tool! LOL!

I measured the vice on the Atlas milling attachment and it's just small enough that I can't fit a block big enough to make my top slide.

At least not without some serious stick out and loss of rigidity.

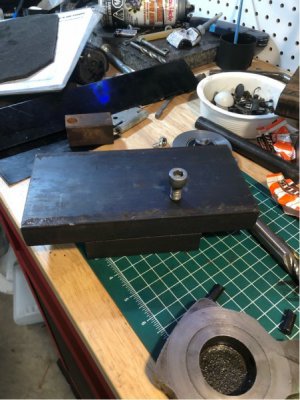

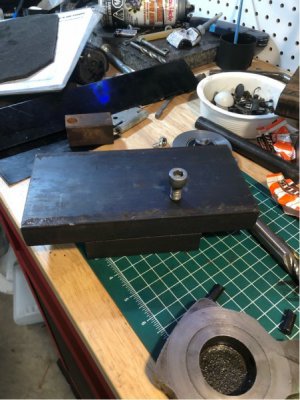

I figured I'd make a 1" thick plate that I can mount in the attachment vice and then mount my block for my top slide to that:

I started thinking about it and bolting a stub to the back of the plate and clamping that in the milling vice is just more stuff "jury-rigged" together than I want to deal with. Not to mention; the milling attachment itself isn't exactly the most rigid assembly to start with. I'd just be adding more joints and more areas for flex to it.

As I thought about it, it struck me that I could just remove the attachment vice and mount the plate right to the attachment slide. That means machining a mount to go over the Atlas stub, so I'd need to add thickness to the plate. Simple solution was to take the piece of 1" plate left over from the cutting the mounting plate and bolt that to the 1" plate, then machine the hole to go over the Atlas stub in that:

That's about as rigid as it's going to get with the attachment. I should be able to work with that.

As an added bonus, the stub for the milling vice is the same diameter as the stub on the cross slide:

So once I've got it made, I can go directly to the cross slide to mill if I want to. That will make it even more rigid than using the milling attachment. I loose 2 axis's of movement going right to the cross slide, but it should work great for applications where the work lines up with the cutter.

Eventually, I may look at machining some T-slots in the plate. But for now, machinist clamps will do.

Then a thread to build a top slide: https://www.hobby-machinist.com/threads/building-an-atlas-th42-compound-slide.76253/

Well, now a thread to modify the Atlas milling attachment so i can make a top slide.

Yeesh, it never ends! Make a tool, to make a tool, to make a tool! LOL!

I measured the vice on the Atlas milling attachment and it's just small enough that I can't fit a block big enough to make my top slide.

At least not without some serious stick out and loss of rigidity.

I figured I'd make a 1" thick plate that I can mount in the attachment vice and then mount my block for my top slide to that:

I started thinking about it and bolting a stub to the back of the plate and clamping that in the milling vice is just more stuff "jury-rigged" together than I want to deal with. Not to mention; the milling attachment itself isn't exactly the most rigid assembly to start with. I'd just be adding more joints and more areas for flex to it.

As I thought about it, it struck me that I could just remove the attachment vice and mount the plate right to the attachment slide. That means machining a mount to go over the Atlas stub, so I'd need to add thickness to the plate. Simple solution was to take the piece of 1" plate left over from the cutting the mounting plate and bolt that to the 1" plate, then machine the hole to go over the Atlas stub in that:

That's about as rigid as it's going to get with the attachment. I should be able to work with that.

As an added bonus, the stub for the milling vice is the same diameter as the stub on the cross slide:

So once I've got it made, I can go directly to the cross slide to mill if I want to. That will make it even more rigid than using the milling attachment. I loose 2 axis's of movement going right to the cross slide, but it should work great for applications where the work lines up with the cutter.

Eventually, I may look at machining some T-slots in the plate. But for now, machinist clamps will do.