- Joined

- Dec 6, 2012

- Messages

- 2,709

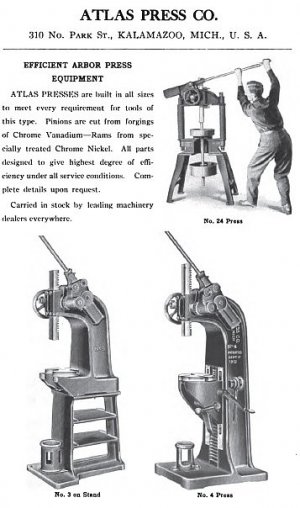

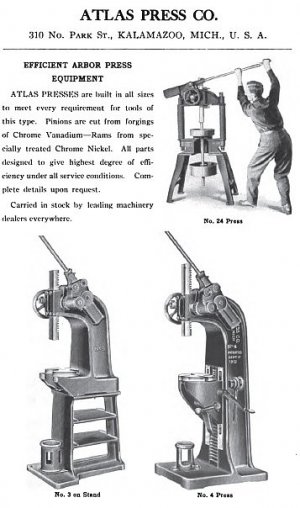

Atlas 3A/5ton Arbor Press Rebuild

As we finalize packing to visit our daughter I thought I'd put out a thank you to everyone here at HM.

I started here a couple years ago with a 10inch hobby lathe and a trip to Tennessee to retrieve a Cincy Toolmaster 1b.

You've all encouraged me to improve and not belittled me as I struggled, and asked silly questions. Thank you.

One of our members Dave Smith in Rochester MN. Sold me a rusty arbor press at far less than scrap price.

He challenged me to make something of it.

As I've seldom been able to refuse a dare, here it is.

I'd hoped to complete the platen before I posted these pics. But, as I look at the calendar, it may be a ways out.

Thus, here you go... Thank you all for the many contributions you make here!!

Have a great year!!

I don't pretend that this is good documentation of a project.

Or, that it is perfect.

However, it does reflect a progression in my skills.

When I got her from Dave Smith. She'd had her rack, handwheel, and bar cut off with a torch. The pawl was missing and the spindle was rusted solid.

Took alot of soaking in Evaporust and some carefully sprayed Kroil. I milled a rack on the Cincy Mill, turned and then slotted a handwheel, drilled out the stub of the old lever and replaced it with a pre-stressed. The band saw pic, is loading a 400pound piece of 10inch round stock for the platen.

As we finalize packing to visit our daughter I thought I'd put out a thank you to everyone here at HM.

I started here a couple years ago with a 10inch hobby lathe and a trip to Tennessee to retrieve a Cincy Toolmaster 1b.

You've all encouraged me to improve and not belittled me as I struggled, and asked silly questions. Thank you.

One of our members Dave Smith in Rochester MN. Sold me a rusty arbor press at far less than scrap price.

He challenged me to make something of it.

As I've seldom been able to refuse a dare, here it is.

I'd hoped to complete the platen before I posted these pics. But, as I look at the calendar, it may be a ways out.

Thus, here you go... Thank you all for the many contributions you make here!!

Have a great year!!

I don't pretend that this is good documentation of a project.

Or, that it is perfect.

However, it does reflect a progression in my skills.

When I got her from Dave Smith. She'd had her rack, handwheel, and bar cut off with a torch. The pawl was missing and the spindle was rusted solid.

Took alot of soaking in Evaporust and some carefully sprayed Kroil. I milled a rack on the Cincy Mill, turned and then slotted a handwheel, drilled out the stub of the old lever and replaced it with a pre-stressed. The band saw pic, is loading a 400pound piece of 10inch round stock for the platen.

Last edited: