- Joined

- May 17, 2012

- Messages

- 105

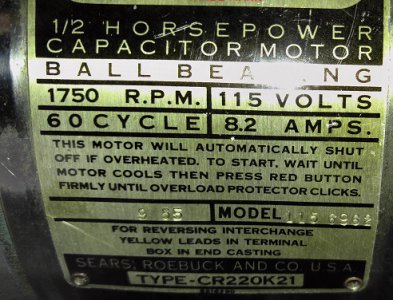

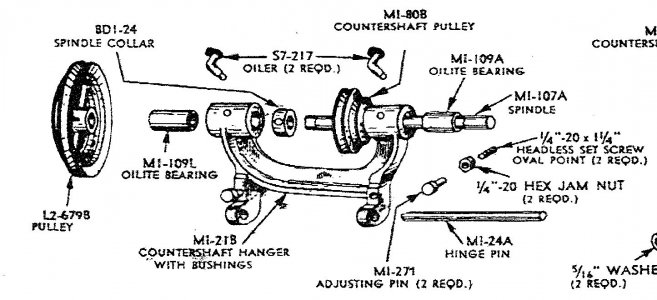

I have a new to me Craftsman horizontal mill. When I bought it, I had to dimantle it to load it into my car. I've now rough cleaned many years of dirt and am reassembling it. I've now run into a problem with the countershaft assembly that is apparent in the attached pictures.

The countershaft mounting point overhangs the mounting pad by about 1/8" to the face of the mill, with about 3/32 showing on the back end of the pad.

When a scale is placed along the side of the spindle drive pulley, it looks like the drive assembly is about 1/4" to close to the front of the machine.(spindle gap.jpg)

With the motor all the way toward the face of the machine on the base, the drive assembly looks to be about 1/4" too far toward the front of the mill. (motor-pulley gap.jpg)

When I look at the cover, it lands on the machine about 1/4" too far to the front of the machine. (cover gap.jpg)

It really seems to me that there is a problem with the mounting of the countershaft that could be corrected by elongating the mounting holes 1/4", which would allow the mount to move toward the rear of the machine and correct all the alignment problems. But, I don't want to do something that drastic in case I'm missing something simple. There does appear to be a subtle difference in the paint colors on the countershaft vs. the machine that doesn't show up in the pictures, but I don't know whether that is significant. It could be that a countershaft assembly that was originally on a different machine was installed, but the previous owner is deceased so I can't ask him.

The mill still had Atlas Press Co. belts on the machine, so the misalignment didn't seem to have a big effect, although the spindle belt was very worn and throwing rubber.

A lot of words, am I missing something simple???

The countershaft mounting point overhangs the mounting pad by about 1/8" to the face of the mill, with about 3/32 showing on the back end of the pad.

When a scale is placed along the side of the spindle drive pulley, it looks like the drive assembly is about 1/4" to close to the front of the machine.(spindle gap.jpg)

With the motor all the way toward the face of the machine on the base, the drive assembly looks to be about 1/4" too far toward the front of the mill. (motor-pulley gap.jpg)

When I look at the cover, it lands on the machine about 1/4" too far to the front of the machine. (cover gap.jpg)

It really seems to me that there is a problem with the mounting of the countershaft that could be corrected by elongating the mounting holes 1/4", which would allow the mount to move toward the rear of the machine and correct all the alignment problems. But, I don't want to do something that drastic in case I'm missing something simple. There does appear to be a subtle difference in the paint colors on the countershaft vs. the machine that doesn't show up in the pictures, but I don't know whether that is significant. It could be that a countershaft assembly that was originally on a different machine was installed, but the previous owner is deceased so I can't ask him.

The mill still had Atlas Press Co. belts on the machine, so the misalignment didn't seem to have a big effect, although the spindle belt was very worn and throwing rubber.

A lot of words, am I missing something simple???