- Joined

- Nov 18, 2012

- Messages

- 1,352

Hi Folks,

90% of the time I use a Jacobs 56B spindle chuck for small work that I do. Next up is the independent 4 jaw, and occasionally one of my collet systems.

My friend has a project and asked if I would machine about 100 spacers that are 12 mm in diameter to close dimensions. Since the spacer is anodized and very slippery and I can only grab about 0.400" of it I figured time to use my 12 mm MT2 collet to get me close to the spindle.

In the 40 years I have had this lathe I have never had a crash...not bragging just saying..but since I will be working close to the threaded spindle decided that it is time for a spindle protector. Awhile ago Jster showed a video using a 1-8 tap to make the internal threads. My spindle is 1-10 and I don't have a tap, and I hate setting up all the change gears to cut the threads, since I have it set up now for a fine finish feed and it is running nice a quiet.

So I decided to just make a counter bored sleeve to slip over the threads and secure it with a brass set screw. After getting the sleeve made out of some 6061-T6 I started to wonder if I could make "fake" threads sort of inserted like false teeth. Since the pitch of the thread is 0.100" it is nice to work with.

So I thought I would try and centre drill, tap drill and tap a series of holes to form two helix. The threads are 8-32. I took a few pictures so here we go.

Centred and located the origin on the sleeve in the rotary table. The idea is to drill the first hole, rotate 90 degrees advance Y 0.025", drill, advance to 180 advance Y to 0.050". continue for one revolution. Then advance another 0.100" to provide a second helix and repeat.

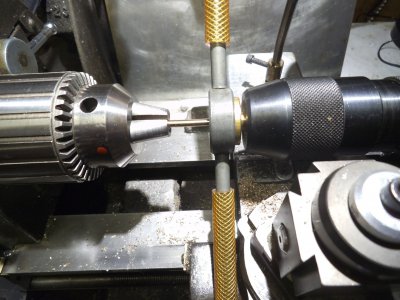

Then use the chuck to locate a tap for hand tapping.

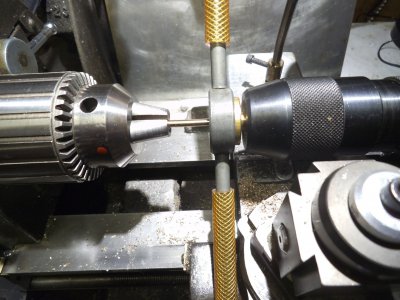

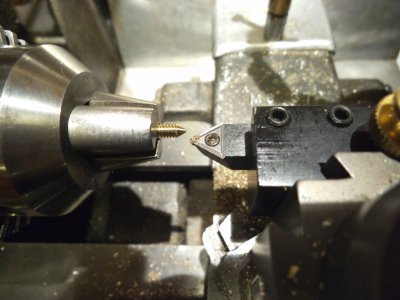

Turn some brass rod and thread\

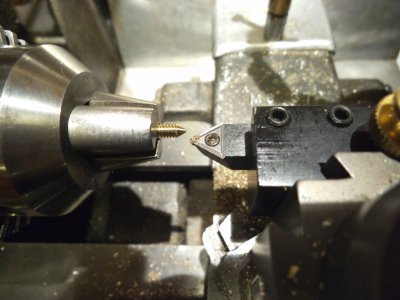

Machine the tips

parting off

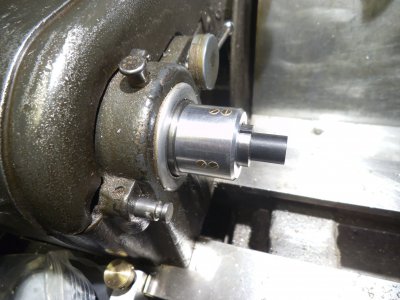

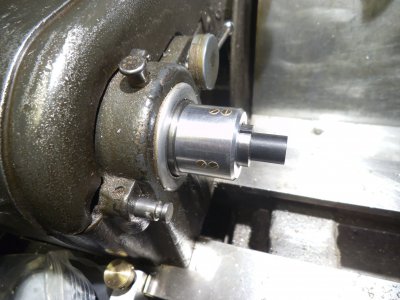

Inside view of sleeve before cleaning up

Installed

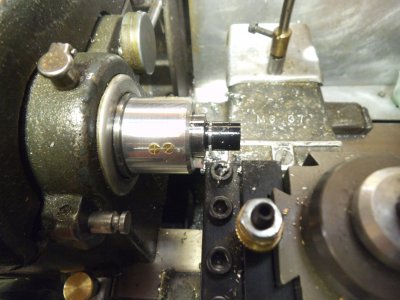

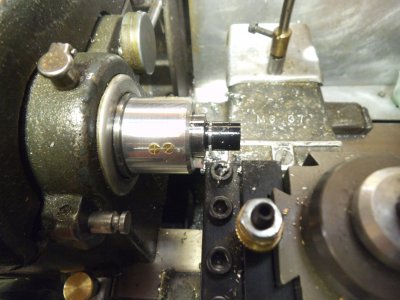

In use parting off spacer

Well what started out intending to me quick and simple, turned out to be more work...But it works very nicely, plus I have threaded before and never tried this method so thought I would share.

David

90% of the time I use a Jacobs 56B spindle chuck for small work that I do. Next up is the independent 4 jaw, and occasionally one of my collet systems.

My friend has a project and asked if I would machine about 100 spacers that are 12 mm in diameter to close dimensions. Since the spacer is anodized and very slippery and I can only grab about 0.400" of it I figured time to use my 12 mm MT2 collet to get me close to the spindle.

In the 40 years I have had this lathe I have never had a crash...not bragging just saying..but since I will be working close to the threaded spindle decided that it is time for a spindle protector. Awhile ago Jster showed a video using a 1-8 tap to make the internal threads. My spindle is 1-10 and I don't have a tap, and I hate setting up all the change gears to cut the threads, since I have it set up now for a fine finish feed and it is running nice a quiet.

So I decided to just make a counter bored sleeve to slip over the threads and secure it with a brass set screw. After getting the sleeve made out of some 6061-T6 I started to wonder if I could make "fake" threads sort of inserted like false teeth. Since the pitch of the thread is 0.100" it is nice to work with.

So I thought I would try and centre drill, tap drill and tap a series of holes to form two helix. The threads are 8-32. I took a few pictures so here we go.

Centred and located the origin on the sleeve in the rotary table. The idea is to drill the first hole, rotate 90 degrees advance Y 0.025", drill, advance to 180 advance Y to 0.050". continue for one revolution. Then advance another 0.100" to provide a second helix and repeat.

Then use the chuck to locate a tap for hand tapping.

Turn some brass rod and thread\

Machine the tips

parting off

Inside view of sleeve before cleaning up

Installed

In use parting off spacer

Well what started out intending to me quick and simple, turned out to be more work...But it works very nicely, plus I have threaded before and never tried this method so thought I would share.

David