I can't remember the process to adjust the headstock bearings on my 618 AtIas lathe.

I had replaced the Timken headstock bearings a couple of years ago. Anyway I just recently decided to give the lathe a proper leveled bench so I built a welded mounting plate out of 2 pieces of 1x3” 1/8” wall rectangular tubing and set those side by side inside some 1x1” angle iron. I beefed up the wood bench it was on:.. leveled the wood bench.... set the steel mounting base on the wood bench and mounted and leveled the lathe.

I then shimed the carriage and adjusted the gibbs to removed the slop. Then checking the headstock play with a .0005 dial indicator. I found my headstock mounting bolts had worked lose so I tightened them and used locktite on the threads.

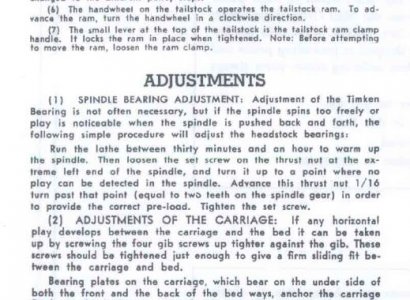

My problem now is I still am getting 3 thousandths of play in my headstock spindle. I know there’s an adjustment for the bearings but for the life of me I can not find an article on the adjustment nor do I remember how it’s done.

I had replaced the Timken headstock bearings a couple of years ago. Anyway I just recently decided to give the lathe a proper leveled bench so I built a welded mounting plate out of 2 pieces of 1x3” 1/8” wall rectangular tubing and set those side by side inside some 1x1” angle iron. I beefed up the wood bench it was on:.. leveled the wood bench.... set the steel mounting base on the wood bench and mounted and leveled the lathe.

I then shimed the carriage and adjusted the gibbs to removed the slop. Then checking the headstock play with a .0005 dial indicator. I found my headstock mounting bolts had worked lose so I tightened them and used locktite on the threads.

My problem now is I still am getting 3 thousandths of play in my headstock spindle. I know there’s an adjustment for the bearings but for the life of me I can not find an article on the adjustment nor do I remember how it’s done.

Last edited: